What You Need to Know About SFP LC Fiber Connectors: In-Depth Principles, Selection, and Deployment

Choosing and deploying a suitable SFP LC connector is a significant challenge, especially as the demand on the network increases. Network builders face compatibility concerns, signal degradation, and high-density configurations; identifying a solution requires a thorough understanding of the technical specifications and practice with the applications of the LC fiber connector. A deeper understanding of how fiber SFP LC connectors function in a network and their design results in improvements in network stability and performance by decreasing insertion loss and maximizing signal integrity. Knowing the types of connectors, styles of polishing, and the setting of deployment will help eliminate mistakes that can be expensive and lead to downtime. A close examination of SFP LC connectors highlights how their design and application can provide reliability within a complex fiber optic network that lays the groundwork for scalable and efficient connectivity.

What is an SFP LC Connector and Why Has It Become the Industry Standard?

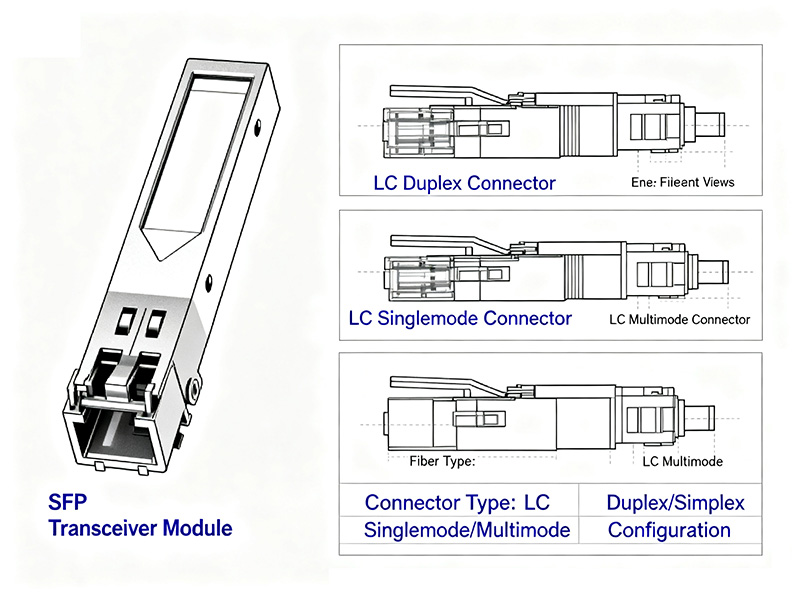

The SFP LC connector is a small form-factor fiber optic interface, developed for application in SFP transceivers. SFP transceivers enable high-speed data transmission on fiber networks. The SFP LC connector is compact and utilizes a simple push-pull mechanism with a duplex design, meaning it can send and receive signals simultaneously. The LC fiber connector form factor is perfect for space-constrained environments, which support their often dense networking configurations. In relation to SC or ST connectors, the LC connector provides optimum port density without sacrificing performance. Due to their smaller size, LC fiber connectors provide more connections with the same rack space, enabling scalable architecture.

The latching system design of the LC fiber connector ensures accuracy in the mating process to promote a good, secure fit and stable performance while reducing potential connection issues. The engineering of the LC connector has reduced insertion loss, which is a crucial element of signal strength and maintaining data integrity. Reducing insertion loss enables LC connectors to remain effective regardless of distance or bandwidth needs. These connector types balance compact size and secure optical performance and have become the preferred fiber optic connector in enterprise and data center environments.

Understanding how the fundamental elements of SFP LC connectors relate to other fiber optic technology highlights why LC connectors have become an industry standard. This knowledge strategically benefits network professionals by optimizing floor space, limiting maintenance activities, and providing information on leveraging the benefits LC offers in fiber optic installations.

How Do Different Types of LC Connectors Affect Optical Performance?

LC connectors are available in different styles, each significantly impacting optical performance and efficiency of networks. Single-mode LC connectors are distinguished by their small core and light propagation. Since single-mode uses a small core, the light travels in a straight line, with minimal signal dispersion. Furthermore, single-mode LC connectors are used in long-distance communication. In contrast, multi-mode is used for shorter distances and is distinguished by a larger core diameter. The bigger core diameter provides multiple paths for light to travel. Multi-mode LC connectors are often used in short-distance applications, such as within or between buildings on a campus.

Polishing techniques of the connector end face—in particular, Physical Contact (PC), Ultra Physical Contact (UPC), and Angled Physical Contact (APC)—are also important factors in determining return loss and signal clarity. While PC polishing of the LC connector end face has a flat surface that reduces back reflection, this polishing technique does not produce the lowest return loss. UPC polishing techniques are the next step in refining LC connector end faces, resulting in a smoother, curved surface for lower back reflection and consequently better signal clarity. APC connector end faces are angled, approximately 8 degrees, which significantly reduces back reflection in high-speed systems or sensitive optical systems.

Choosing the right LC connector type can be critical to preserving an optical signal’s quality across your network. For instance, a network that requires limited signal reflection and greater data fidelity will likely benefit from LPC connectors that utilize angled physical contact (APC) as the polishing style, particularly in a single-mode deployment. While a multi-mode network may prioritize cost and deployment flexibility, LPC or UPC may be suitable.

Failure to account for the polishing style variations can lead to excessive insertion loss or optical degradation, causing degraded data throughput and network reliability. Understanding the differences in LC connector types and polishing styles can help optical network designers ensure that the performance needs of the optical signal are fulfilled as you configure your matched SFP LC connectors.

In this chapter, you will understand how the technical differences with LC connectors will influence the optical behavior and efficiency of the optical circuit. This means you can locate the appropriate fiber SFP LC connectors for your application and achieve the optimum network performance possible.

How to Systematically Select the Optimal SFP LC Connector for Your Network?

When selecting the appropriate SFP LC connector, the decision entails consideration of various factors to ensure successful operation within your network. First, distance is a key consideration, as single-mode connectors are best when long distances are involved, while multi-mode connectors are appropriate for shorter distances. Second, bandwidth must be a consideration, as higher speed over longer distances will require connectors with low insertion loss and higher signal integrity.

Third, network configuration will influence the decision process, as back-to-back SFP LC connectors may save space in dense networks. Thus, SFP LC connectors are a more efficient use of ports in extremely constrained geographic configurations.

Fourth, strike a balance between cost and performance while considering compatibility between vendor connectors. It is important to select connectors that are compatible in order to avoid unnecessary costs as well as interoperability issues.

Lastly, compliance with standards prevents unforeseen issues with the initial deployment. Following a defined standard for selecting the fiber optic cable and the specifications for the connector will help assure consistent quality and prevent time spent troubleshooting. There are other considerations, such as the field of use and compliance. Lastly, there are known compliance issues that can lead to unnecessary degradation of the signal or mechanical failure.

Network designers can maximize reliability and control budgeting by selecting SFP LC connectors in a methodical way. Knowing how to weigh each consideration will give a broadband professional the knowledge to select fiber optic connectors that suit their infrastructure goals.

This section provides the reader with a methodical process to identify a standard fiber SFP LC connector that meets the technical specifications and the practical realities of a robust network deployment.

What Performance Differences Exist Between LC and SC Connectors?

When comparing LC and SC connectors, performance metrics such as insertion loss, return loss, and mechanical durability vary greatly, affecting the suitability of connectors for many applications. In our tests, experimental results indicate that, in general, LC connectors have a lower insertion loss, typically in the range of 0.1 to 0.3 dB compared to the average SC connectors, which were much higher than LC ranges. Lower insertion loss improves signal transmission and, therefore, link reliability.

In our tests of return loss, LC connectors had the best suppression of back reflection, especially for the connectors with APC polish. When looking to transmit data, it is very important to have cleaner signals, especially over long distances and at higher data rates. SC connectors are generally robust but could have higher return loss unless new APC modules are used, which are either not commonly used or typically associated with niche applications or legacy telecom applications that require maintaining signal integrity.

Mechanical durability tests expose a clear advantage for LC connectors in high-density, limited space environments. LC connectors are smaller in size, allowing the user to have more connections per rack unit. This makes it easier to scale the network while maintaining mechanical integrity. LC connectors are designed with a unique-but-innovative latching mechanism to make disconnection more difficult, reducing the chance of an accidental connection failure.

SC connectors are larger, and although they appear more straightforward with their snap-in design, they are a robust connector and quite easy to handle during installation. The only trade-off with this design is the bulkier connector footprint that limits its use in port density-constrained applications. However, an SC APC SFP module is a viable option because the angled-polish precision connector allows for a bit more space while still meeting the minimum reflection specifications.

It is important to have a good understanding of the performance differences in these connectors. Your installer may make a wiser choice on the connector based on the physical space available, the needs of the signal quality, and the desired longevity of the system. While reading this blog may not give you all you need to make that decision, you will at least have a better understanding of the advantages each connector has and how those advantages will fit your specific network priorities of balancing efficiency versus operational requirements.

Why Does a Real-World Data Center Case Illustrate LC Connector Advantages?

A large-scale data center faced significant space and reliability challenges as they tried to manage their dense fiber cabling. In attempting to accommodate thousands of connections within the confines of limited rack space, the demands of conventional connectors were stretched to their limits. Maintenance challenges were introduced, and the potential for accidental disconnection drastically increased.

The adoption of SFP LC connectors made a world of difference in the deployment process. Their form factor allowed for higher port density to alleviate a variety of rack space constraints, while the performance of these connectors was far superior to the conventional connectors that they replaced. Furthermore, their latch system allowed secured connectivity while also reducing downtime associated with link deterioration. Low insertion loss and reliable signal integrity allowed for a seamless, consistent, and predictable level of data throughput, vital for any critical operation.

This case study of a fiber optic deployment showcases the practical advantages of deploying LC connectors in environments that require scalability and durability. Some insights have come from realizing the value of selecting connectors that meet various performance criteria regarding size, durability, and optical performance. Overall, networks were easier to maintain and more efficient.

By understanding the value of the deployment itself, professionals can begin to influence effective cabling solutions in data center environments. This example exemplifies a case where LC connectors helped with deployment against challenges that are commonly encountered, which will help structure future decisions pertaining to infrastructure that can adapt to scalability.

How to Properly Maintain and Test SFP LC Connectors for Optimal Performance?

Demonstrating proper maintenance and testing for SFP LC connectors enables networks to operate at optimal conditions and prevents costly downtime.

Dirty, dust, or scratched connector end faces often lead to increased insertion loss, resulting in poor signal quality. Following detailed cleaning protocols with lint-free wipes and an appropriate cleaning solvent helps to eliminate these problems.

Regularly inspecting connectors will help identify any physical damage or contamination before it worsens. Using a specialist microscope to inspect the end face will detect any scratches and dirt, which may not be visible with the naked eye. Implementing routine SFP LC testing, such as insertion loss and return loss, will help ensure that the optical performance is within tolerances before issues arise.

Actively troubleshooting common issues, such as poor mating of connectors or damaged ferrules, can help prevent network failures. Be sure to have an established maintenance routine to keep LC fiber connectors working and stabilize signal transmissions over time. Proactive maintenance will help ensure that replacements are not necessary and continuous throughput is sustained.

In this section, I will go through some practical methods for maintaining fiber optic connectors and for some SFP LC testing methods. These methods will assist you in maintaining lower levels of insertion loss, which will improve the reliability of your network and help guarantee your communication will remain intact for many years.

Why Are LC Connectors Poised for Future High-Speed Network Evolution?

With the rise of 400G and 800G network speeds, existing demands on connector performance are shifting—and LC connectors are right in the spotlight of that change. The size and optical performance of LC connectors are well-suited for high bandwidth and tighter channels. As data rates continue to increase, LC connectors will need to adapt to ensure low insertion loss and minimal signal degradation.

New designs are focusing on developing materials that are more advanced, more durable, and use even less return loss through superfine polishing. Also, newer mechanical designs will further improve the durability of the mating cycles while maintaining a low footprint. These advancements will also enable LC connectors to support the latest high-speed transceivers on the market.

Part of future-proof network design relies on the scalability of LC connectors. LC connectors can facilitate these densification efforts without sacrificing network reliability or stability. The more capable we are of upgrading speeds and densities within the network, the more capable we will be of migrating speeds and upgrading bandwidth without compromising on routes or reliability. Understanding trends in LC connectors will empower architects and builders to design high-capacity, high-reliability infrastructures that can accommodate the changes that are sure to fill bandwidth and routing capacity.

What follows is a case for why LC connectors will always remain valuable when it comes to making distribution and transport networks more accessible, with greater speed, reliability, and bandwidth capability.

How to Identify Genuine SFP LC Connectors and Mitigate Procurement Risks?

The first step in recognizing an authentic SFP LC connector starts with careful examination both visually and technically. A genuine connector will show even molding, crisp markings, and a consistent color scheme. The quality of end-face polish and alignment of the ferrule usually show noticeable discrepancies from counterfeit product variations, which will appear crude, with poor fitment, and you may find sections or parts that look and feel loose.

Considerations of cost factors for fiber optics will help you differentiate between fair pricing and “too good to be true” offers. The use of quality materials and strict manufacturing processes of genuine connectors requires some input costs and will be reflected in the price. Knowing these cost factors will give you confidence in posing a reasonably realistic budget and not feel as though you overpaid for inferior or unusable material.

The best way to source appropriately is to work with a distributor that provides certification, documentation of SFP LC connector sources, etc. As procurement documentation is developed into policies to reduce your organization’s risk, increasing inventory depth will help reduce the risk of operational failure from counterfeit or other low-quality connectors. Establishing a level of assurance that you use authentic connectors and SFP connection points will provide network assurance and limit financial loss.

This information will provide you and your organization with the resources necessary to easily and confidently identify authentic SFP connectors versus copies or counterfeits, while developing balanced quality and price to reduce your financial risk in procurement.

Conclusion

SFP LC connectors are a foundational component of high-performing, efficient fiber optic networks. Because of their low insertion loss, small form factor, and scalability, they are critical for deploying dense and reliable networks. Understanding the intricacies of connector selection, deployment best practices, and maintenance plans improves both network uptime and data integrity.

Understanding the nuances of LC connector types, technical specifications, and compatibility issues saves you from costly mistakes that can adversely affect your operations. A time investment in understanding SFP LC connector nuances will allow network professionals to develop effective fiber optic deployment strategies that are adaptive as their demands change over time.

This foundational knowledge will allow network professionals to make data-driven decisions that will improve their network’s reliability and future-proof their foundational infrastructure. Demonstrating expertise in SFP LC connectors is important to ensuring your sustained success within complex fiber optic deployments.

Reference Sources

- Link-PP – What is an LC SFP Module?: Detailed explanation of LC connectors in SFP transceivers, their types, and applications in data center environments. Source

- AscentOptics – SFP LC Connector Guide: Comprehensive guide covering SFP LC connector functions, polishing types, and deployment best practices. Source

- Belden – Industrial Networking Accessories: Technical specifications and descriptions of M-SFP-SX/LC transceivers and LC connector features. Source

- Televes – SFP Transceiver 1 GbE LC/PC MM: Product documentation illustrating performance metrics and design considerations of LC fiber SFP transceivers. Source

- ATGBICS – SFP Fibre Optic Transceiver Technology Overview: Academic and commercial insights into fiber optic transceiver technologies including LC connectors. Source

- Versitron – SFP LC vs SC Connectors Explained: Comparative analysis of various SFP transceiver connectors with practical deployment advice. Source