Understanding Fiber Optic Color Codes: A Simple Guide

Fiber optic cable color codes are an industry standard meant to identify each fiber within a fiber optic cable or specify the fiber type. Understanding these codes is an important part of any technician’s role in the installation, troubleshooting, and maintenance of new and existing fiber-optic networks.

Without color codes, complex fiber cables would quickly become a confusing mess, and cabling would be riddled with mistakes, resulting in downtime and misconfigurations that affect a company’s bottom line.

The most common standard for fiber optic color coding is the EIA/TIA-598-C standard, which identifies jacket colors (the outer jacket around each single-mode or multi-mode fiber), internal fiber color (the colors of the individual internal fibers), and connector color codes (colors assigned to connectors that go into the devices). These color codes help drive efficiency and accuracy during the management of fiber optic networks and when deploying communication infrastructure.

This article will explore fiber optic color codes: jacket color codes, fiber color orders, connector color codes, and real-world applications.

Fiber Optic Color Coding Standards Overview

The fiber optic color code is primarily based on the EIA/TIA-598-C standard, the protocol for the identification of fibers that manufacturers and installers across the world follow.

The EIA/TIA-598-C specification defines a set of colors that fiber jackets, the sequence of internal fibers, and connector colors will follow for use throughout the industry. Other standards for fiber optic color codes include IEC and DIN, especially in Europe and Asia, which are built on or complement EIA/TIA-598-C.

Fiber optic color coding can be divided into three main categories: outer jacket colors, internal fiber colors, and connector colors.

Outer jacket colors allow the technician to quickly identify what types of fiber, like single-mode or multimode, are being used. Internal fibers follow a color order within the cable, making it easier to identify the fiber without having to separate them, as is required during splicing or termination. Connector colors represent the fiber type and polish style for compatibility and installation purposes.

Military applications may use different or additional color codes to comply with their operational requirements. Military color codes can be very different from civilian or commercial color codes. Fiber and fiber coding in the military require installation technicians to be aware of color code variations when working on military and government projects.

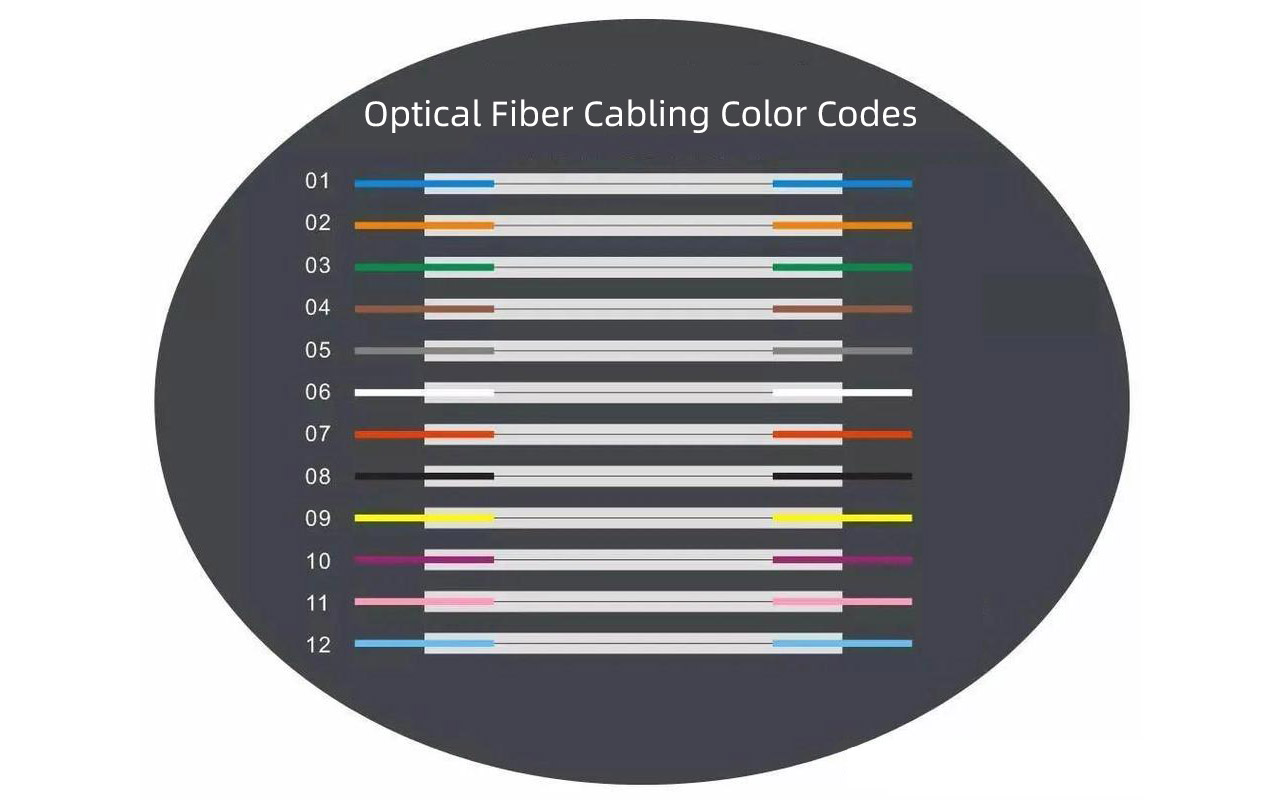

At the heart of fiber color coding is the 12 standard colors arranged in a fixed order: Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, and Aqua. This color order repeats with cables that require more than 12 fibers, along with a stripe or marker to identify associated codes. This color order is necessary for maintaining consistency and avoiding any mishaps when managing fiber.

Jacket Color Codes for Different Fiber Types

The color of each jacket helps to quickly discern the type of fiber optic cable and the function it is intended for—whether it is indoor or outdoor, single-mode or multimode.

Using these visual identifiers, a technician or network engineer can quickly determine the fiber specifications without having to look at a printed label or use measuring devices. Properly color coding fiber cable increases efficiency during the process of installation, maintenance, and troubleshooting by eliminating mistakes.

| Fiber Type | Non-Military Jacket Color | Military Jacket Color | Suggested Print Nomenclature |

| OM1 62.5/125µm Multimode | Orange | Slate | 62.5/125 |

| OM2 50/125µm Multimode | Orange | Orange | 50/125 |

| OM3 50/125µm Laser-Optimized | Aqua | Undefined | 850 LO 50/125 |

| OM4 50/125µm Laser-Optimized | Aqua/Violet | Undefined | 850 LO 50/125 |

| OS1/OS2 Single Mode | Yellow | Yellow | SM/NZDS, SM |

| Polarization Maintaining Single Mode | Blue | Undefined | Undefined |

For enhanced clarity in mixed fiber cables, often containing assorted fiber types, there are printed legends on the cable jacket.

When color coding is not enough (which may happen in more complex installations with multiple fiber types), these legends assist technicians in distinguishing fiber types.

In real-world installations, jacket color coding is helpful. In data centers with high-density cabling, technicians can easily identify the fiber based on the color-coded jacket, which will minimize downtime during upgrade or repair.

In outside plant environments, jacket color coding helps field technicians differentiate between fibers designed for outdoor environmental exposure and those designed for indoor use. In premises wiring, jacket colors are used to help the technician differentiate between single-mode and multimode fibers to ensure proper input/output connections and proper network performance.

Jacket color coding is critical to fiber optic cable management. It streamlines the workflow, creates less opportunity for human error, and helps with efficiency by providing a fast and effective way to quickly identify cable types at a glance.

Internal Fiber Color Sequence and Ribbon Fiber Color Code

To help maintain organization and make identification easy during installation and maintenance, optical fibers inside fiber optic cables are designated by a standard color sequence.

The most common color designation uses a 12-fiber color sequence as follows:

| Fiber Number | Color |

| 1 | Blue |

| 2 | Orange |

| 3 | Green |

| 4 | Brown |

| 5 | Slate |

| 6 | White |

| 7 | Red |

| 8 | Black |

| 9 | Yellow |

| 10 | Violet |

| 11 | Rose |

| 12 | Aqua |

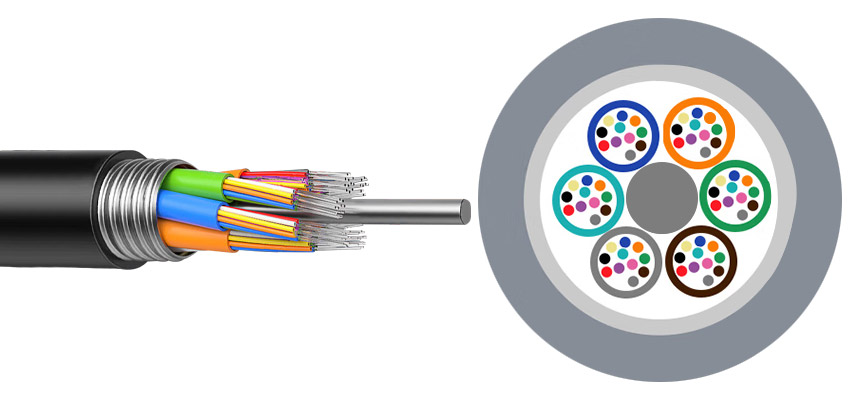

The color sequence appears again in cables with more than 12 fibers. Additional markings can include stripes or binders for identification of fiber groups.For example, in a 24-fiber cable, the first twelve fibers follow the standard base color schema, and the second group of twelve fibers uses the same base colors but includes a stripe or other distinction.

This system helps prevent confusion as the technician is splicing or testing. In high-fiber-count cables, color-coded fiber ribbons are also used. These group fibers into flat ribbons, each with a unique color sequence, allowing for efficient mass fusion splicing and cable management.This process is designed for improved efficiency, allowing a technician to manage multiple fibers at once while still maintaining color identification.

Memorizing the fiber color order can be overwhelming, and many technicians have developed mnemonic devices to help. A common phrase for the first six colors is: “Blue Orange Green Brown Slate White.”Just using the first six colors adds accuracy to your installation and troubleshooting efforts. Knowing all twelve colors can help as well.

It is important for anyone working with an optical fiber network to memorize and understand the optical fiber color order or fiber splice color code. It is also a good practice to keep a cheat sheet or reference for optical fiber color coding to maintain a consistent and error-free working knowledge of the fiber.Much of your network’s reliability depends on proper color coding of the fiber.

Connector Color Codes and Their Significance

The color coding of the connectors gives immediate visual cues for the installer to recognize what fiber type and polish style the connectors employ.

Knowing the different polish styles allows the installer to correctly pair two connectors. The two most used polish styles are UPC (Ultra Physical Contact) and APC (Angled Physical Contact). UPC connectors typically have a blue or beige color, while APC connectors are green.

The back-reflection performance differs based on the polish style, and APC will generally provide lower back-reflection than UPC. This is ideal for high-precision single-mode applications.

| Fiber Type | Polish Style | Connector Color | Typical Use Case |

| OM1 62.5/125µm | UPC | Beige | Multimode legacy systems |

| OM2 50/125µm | UPC | Beige | Multimode legacy systems |

| OM3/OM4 50/125µm | UPC | Aqua | High-speed multimode networks |

| OM5 50/125µm | UPC | Lime Green | SWDM multimode |

| Single-mode OS1/OS2 | UPC | Blue | Standard single-mode |

| Single-mode OS1/OS2 | APC | Green | Low back-reflection single-mode |

Standard connector types, such as SC and LC, adhere to these color conventions to ensure compatibility and simplify network design.In fiber optic cabling, it’s important to have proper color coding to avoid mismatches that may cause signal degradation or equipment damage.The installer ensures that the fiber and the connector are compatible by checking that the connector colors match before proceeding to splice or patch the fibers—avoiding an expensive mistake.Understanding the color and use of fiber optic connectors is important for a reliable network configuration and, therefore, for efficient installation, troubleshooting, and upgrading of networks.

Real-World Applications and Scenario Analysis of Fiber Optic Color Coding

Color coding in fiber optics drives installation efficiency and minimizes errors in data centers, telecommunications, and enterprise networks.A standardized fiber order color system enables technicians to quickly identify fibers for cable management and connection. This clarity is crucial in data centers with thousands of fibers, where simple identification mistakes can lead to costly downtime.Color codes also facilitate faster fault isolation and resolution. Once a technician locates a fault, they can trace color-coded fibers through patch panels and splices without hesitation, allowing quicker repairs and reduced outage time.

Using detailed fiber optic color coding charts provides quick references to the fiber sequence and jacket colors.During upgrades, color codes improve the efficiency of network expansions and the integration of new fiber types. Emerging fiber types, like OM5 (lime green), must be identified accurately for proper documentation and integration.

In short, following established standards and methodologies while using fiber optic color charts helps ensure that networks are well-organized and future-proof.Color-coded networks enhance visual management and reduce documentation errors over time as networks grow. Overall, consistent fiber optic color codes are critical to reliable and scalable fiber optic networks.

Frequently Asked Questions

What is the significance of the fiber optic color codes?

They offer a universal method to identify fibers and fiber types, aiding in installation, troubleshooting, and maintenance.

How will I know if the fiber is single-mode or multimode based on color?

Single-mode fibers are normally jacketed in yellow. Multimode fibers use orange (OM1/OM2) or aqua (OM3/OM4). Connector colors also help identify the type.

What are the colors for the first 12 fibers typically included?

Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, and Aqua.

Do the fiber color codes change from region to region or based on the manufacturer?

Most commercial installations follow the EIA/TIA-598-C standard, though regional and military variations exist.

How do the connector colors fit into fiber optic color codes?

Connector colors correlate with fiber types and polish styles:

OM1/OM2 – Beige,OM3/OM4 – Aqua,OM5 – Lime Green,Single Mode UPC – Blue,Single Mode APC – Green.

What happens if I ignore the color codes when splicing fibers?

You risk splicing different fiber types together, which can result in signal loss and network downtime.

Tips for memorizing fiber color codes?

Use mnemonic devices like:

“Blue Orchids Grow Because Squirrels Want Rum, Black, Yellow, Violet, Rose, Aqua.” Color coding charts also serve as excellent references.

Conclusion

The use of standardized fiber optic color codes relates directly to the reliability and maintenance of a network. By ensuring that colors remain consistent—jacket color, internal fiber color, and connector color—the potential for mistakes is decreased, speeding up installation and troubleshooting.

Standards like EIA/TIA-598-C also enhance cross-equipment and manufacturer compatibility.Using visual aids like color coding charts and mnemonic devices helps technicians quickly recall fiber codes, improving accuracy and repeatability.

As advancements in fiber optics continue, staying updated on standards and best practices, while maintaining fiber color awareness, ensures scalable, reliable, and organized network infrastructure for the future.