Ultimate Guide to SFP Module Temperature: Strategies and Practices to Prevent Overheating Disasters

Although compact in size, SFP modules are of central importance to virtually all network communications. However, there is a hidden vulnerability to SFP modules that can lead to network outages or permanent damage to hardware without the user’s knowledge—overheating. And by the time you realize an SFP module has overheated, things could have already gone awry, leading to costly downtime and repairs.

It is imperative to understand how to address SFP module temperature fluctuations in order to keep your network properties stable and minimize any risky ventures with your investment. In this guide, we will cover everything from what causes heat, to monitoring your SFP module temperatures in real time, techniques for managing heat, and preventative maintenance. With these best practices, we can prevent the overheating headache from happening to begin with, leading to better network operations overall.

Why Is SFP Temperature the Invisible Killer of Network Stability?

SFP temperature can quietly threaten network stability much more than many understand. Even the slightest increase above the safe level will impact performance, and it’s also proven to reduce the overall lifespan of your SFP or equipment. When you think of your network as a runner, heat is like cramping, and when your race pace slows down after all your training, you are at risk of injury. In this instance, injury means outages or failure of the hardware.

An increase in temperature directly correlates to the increase in failure of optical modules, which are the key to transmitting data seamlessly. When heat builds up in your network, signal quality declines and error rates go up—connection will occasionally be sporadic or stop altogether. Connecting this all together is known as the SFP temperature effect and is the reason reliability can’t be counted on by enterprises.

The operating temperature can directly relate to the lifespan of optical modules. Certain modules running too hot for an extended period of time will fail to operate effectively, resulting in a surprise replacement. This leads to network downtime and additional cost to maintain the existing network.

Typical impacts of higher SFP temperature include:

- A lack of signal accuracy leading to data loss or retransmissions

- Internal components wear out faster than limits, resulting in the optical modules winding down faster than expected

- Network instability due to the module—leading to unpredictable outages

As is so often the case, when you can’t see the threat, you don’t understand the threat. Understanding SFP operating temperature is important in a way that secures every other component or operation of the network as it relates to performance and longevity. That is why preventing an overheating failure is so crucial to having a reliable and efficient operation.

What Causes SFP Modules to Overheat? Four Main Heat Generation Factors Explained

SFP modules run on power and generate heat, and as you know, heat can build up and cause overheating for a number of key reasons. Knowing the reasons before overheating happens will help you mitigate problems with overheating and ultimately maintain a healthy network. Here are the four areas that contribute to overheating:

SFP Power Consumption

You may see different SFP model numbers, such as 10G, 25G, or 40G, and it’s important to know that power consumption varies greatly for these different module types. As a rule of thumb, if it is a higher-speed module, it more than likely uses more energy and then generates more heat. You can think of this similar to a car engine going faster—it’s burning more fuel per hour and creating more heat in the engine. The SFP power consumption is a key driver of how much heat a module generates when powered on.

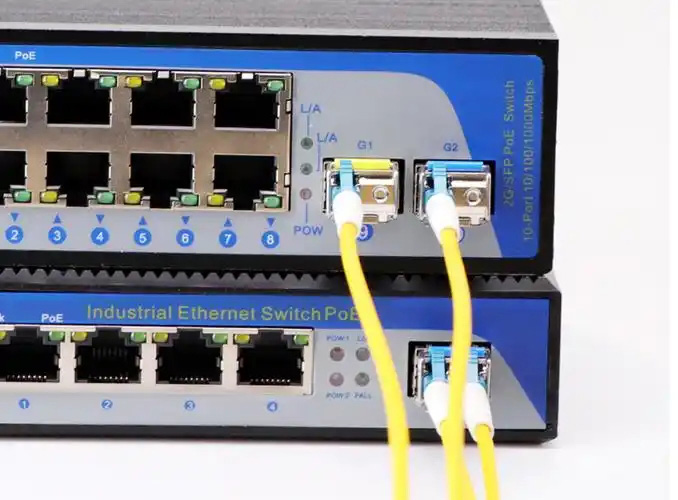

Port Density

Too many SFP modules placed tightly together in a piece of equipment, like in a switch or router, can concentrate heat. Each port is generating heat, and they are closely spaced together, which means they are sharing that heat, thereby increasing the temperature on any given port. Think about several light bulbs in a very small room—collectively, they increase the room temperature much faster than one bulb would.

Ambient Environment

The air surrounding an SFP module determines how effective and timely heat is dissipated into the environment. If you are in a poorly ventilated data center or cabinet, or your room is hot, then cooling will be impeded, and that will lead to elevated SFP temperatures. Environmental heat is like humidity on a hot and sticky day—it makes it a challenge for devices to cool.

Insufficient Cooling Solutions

If cooling is insufficient, heat will build up quite rapidly. Passive heat sinks, fans, or incoming airflow must be adequate for the equipment used. If adequate cooling is not provided, the SFP modules will not be able to dissipate heat properly and will eventually exceed thresholds for some equipment specifications, ultimately risking failure.

In summary, overheating occurs when power consumption rises, multiple ports are grouped together as heat sources, ambient heat limits dissipation, and cooling is insufficient. Specifying what action you take in each of the four areas will provide balanced examples of heat generation and heat removal, to save network components and provide stable performance.

How Can You Spot Early Warning Signs of SFP Overheating Before a Failure?

It is important to recognize the signs of SFP overheating early to prevent network outages. Just like a car gives indications that it is going to stall, so does your network; the difference is, the signs generally happen long before a module has failed, and having the ability to recognize those signs is crucial to being able to act in a timely manner.

Temperature Logs

Keeping temperature logs and monitoring the information over time will show unusual spikes. Most SFPs support Digital Optical Monitoring (DOM), which reports the current temperature. Monitoring the logs regularly will help you recognize patterns of evidence that convince you overheating is a concern.

Unexpected Noise or Speeding Up Fans

Cooling fans may take it to the next level and could speed up or potentially become loud as they try to cool off the device with rising heat. When fans suddenly speed up their RPM range or begin making noises that are out of the normal, it is most likely an indication that something internal is heating up. Comparable to a blow dryer being plugged or unplugged, it could mean the device is stressed out and starting to heat up.

Intermittent Connectivity Issues

Heat is an enemy of signal integrity, and signals interrupting data transmission can easily point back to SFP temperature issues. If the connection is interrupted multiple times, or the data transfers experience sluggish speeds or seem to freeze, those “glitches in signal” are similar to the light in a typical old-fashioned light bulb—if it keeps blinking, you will know it will not be long until it goes out completely.

Network Temperature Alert Systems

Multiple network devices allow you to configure alerts on the temperature of the device. Those alerts can be helpful because they give you an indicator to check on temperature. If the temperature exceeds a certain limit, then a network alert could occur, which allows the administrator to take corrective action faster due to concern regarding the temperature.

A few key reminders to help recognize overheating early:

- Review and analyze temperature data on a regular basis

- Watch for abnormal noise or suddenly speeding cooling fans

- Investigate or monitor sluggish or above-normal slowness issues when using the network

- Implement a real-time network device temperature alert system, if the hardware supports it

Awareness and highlighting early signs of overheating can help to improve the life expectancy of the optical module and the network. Addressing issues in a timely manner early on can help to mitigate small problems from becoming costly failures.

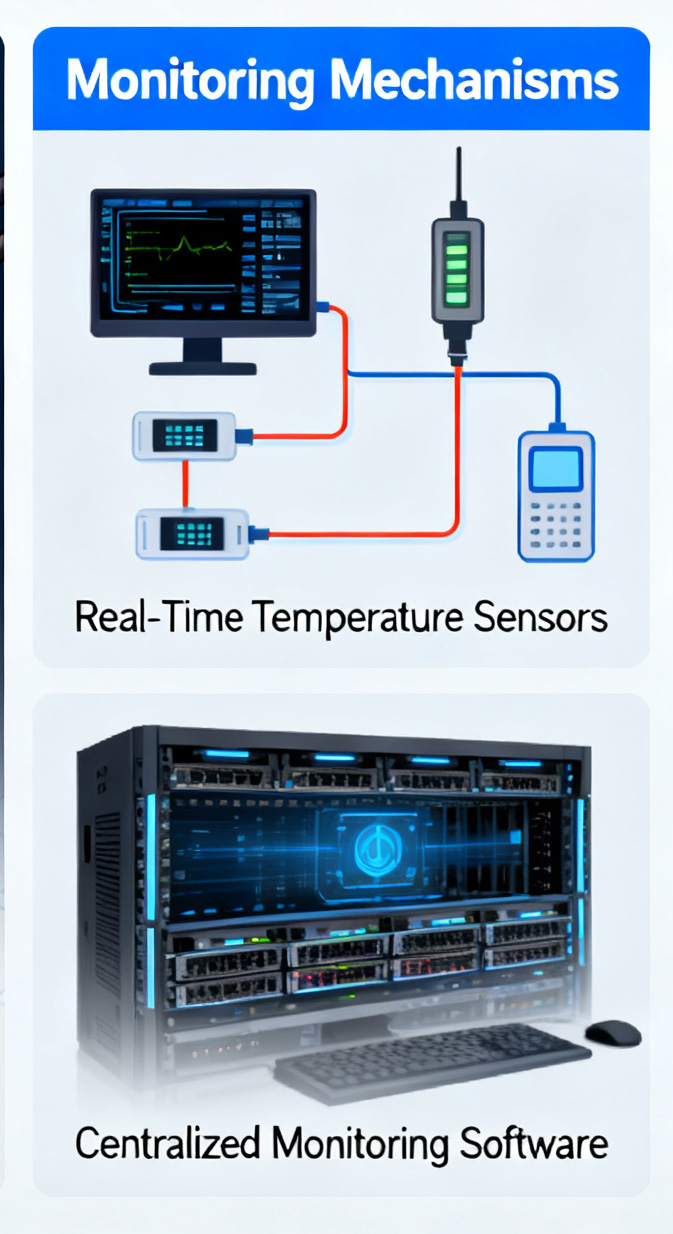

How to Monitor SFP Temperature in Real Time Using DOM and SNMP?

Ensuring SFP temperature management involves continuous, accurate observation over time. Digital Optical Monitoring (DOM) is an embedded thermometer within the module, providing not only SFP temperature readings but also crucial data like voltage and laser bias current. Therefore, monitoring SFP temperature levels could not be any simpler or more trustworthy.

DOM is a continuous reader of these parameters and conveys the information via the module’s interface. Network engineers can observe temperature trends without having to open the equipment or interrupt service. You can think of DOM as a smartwatch for your SFP, continuously reviewing health metrics.

To receive alerts in real time and store everything for review, integrate Simple Network Management Protocol (SNMP) with DOM readings. SNMP will allow the extraction of temperature data from multiple devices and generate a dashboard for continuous monitoring.

The steps for SNMP configuration to monitor SFP temperature can simply be summarized as the following:

- Enable SNMP on your network devices such as Cisco or Juniper switches

- Identify the OID for the SFP module temperature-related data

- Create temperature thresholds for alerts to notify your engineers of abnormal readings

- Utilize a network management system to store and visualize your temperature data

Once enabled, SFP temperature readings will be used to quickly respond to an overheating event discovered by SNMP alerts. Monitoring temperature incorporated with the DOM via SNMP creates stability in the network by responding to issues early while also confirming cooling is effective over time.

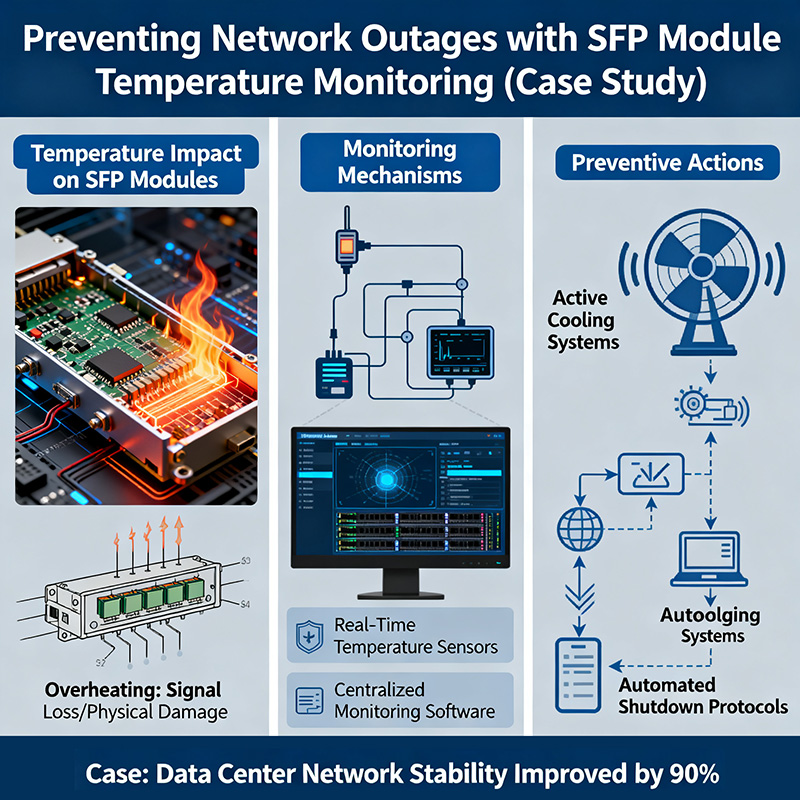

What Can We Learn From a Real Case Where Temperature Monitoring Prevented Network Downtime?

Once upon a time, an organization had gone for months experiencing network downtimes that had no apparent cause or explanation for the IT professionals involved. After a few months of troubleshooting various aspects of the network, they discovered that the SFP modules would get hot as traffic peaked. This is a clear example of how simple temperature monitoring helps to prevent major network downtimes.

The organization had engaged a temperature monitoring system that gave them real-time alerts, took the temperature of certain parts of the infrastructure (Digital Optical Monitoring), and enabled alerts using SNMP, which is a common management system in IT. They had set upper and lower threshold alarms, which triggered alerts to the IT team members as they approached unsafe levels of high and low temperature. This way, the IT team could take necessary action to help prevent disaster before a hardware failure happened.

After monitoring for just a few days, the monitoring sporadically indicated a slightly higher than established limit in several modules. The IT professionals acted within minutes to improve the cooling measures for the SFP modules and redistribute some workloads. Although the system indicated an alarm of risk for outage, the thorough monitoring system and steps taken helped mitigate downtime and reduced the likelihood of damaging an optical module.

The following is a summary of the SFP overheating case study:

- Monitor temperatures with alarm thresholds as early warning indicators to identify temperature limits

- Use monitoring systems with preset limits for fast intervention

- Slight temperature increases indicate system risks we can manage

- The key to mitigating network downtime is maintaining constant temperatures

This example showcases monitoring as a powerful tool to mitigate threats. Having temperature monitored and controlled as part of your network helps to identify issues before they develop into costly, service-interrupting problems.

How to Choose Between Passive, Active, and Environmental Cooling Solutions for SFP Modules?

Maintaining the appropriate operational temperature for SFP modules is dependent upon a cooling method selection. Cooling methods vary by cost, complexity, and effectiveness, making it important to match cooling methods with the needs of the network.

Passive cooling consists of heat sinks or thermal pads that are attached to modules. The heat sinks or thermal pads will absorb and dissipate heat, with no moving parts, similar to when you cook something in a metal pan on the stove. Once it is removed from the heat source, it cools down fairly quickly. Passive cooling methods tend to be cheaper and do not require any power, but they provide the best cooling effectiveness when there is already sufficient airflow.

Active cooling relies on fans or blowers to move air across the modules to remove and dissipate heat. Active cooling methods will quickly force heat away, much like if you were using a fan to cool off on a hot day. Active cooling is also better than passive cooling at managing high evaporative heat, but they are more costly, noisier, and require maintenance consideration.

Environmental cooling focuses on the immediate surrounding data center environment by engaging HVAC systems (heating, ventilation, air conditioning) or cold-aisle/hot-aisle approaches. If the room temperature and airflow are managed, this is the best for all equipment to have optimized conditions regardless of the type of equipment, including SFP modules. However, there will be a larger capital investment involved and changes to current infrastructure.

| Cooling Type | Cost | Effectiveness | Ideal Scenario |

| Passive Cooling | Low | Moderate (needs airflow) | Small setups, low heat output |

| Active Cooling | Medium-High | High | Dense racks, high traffic |

| Environmental Cooling | High | Very High | Large data centers |

Selecting the appropriate cooling solution depends on several factors, including the heat dissipation requirements of the SFPs, space limitations, and budget considerations. Options can even be combined to provide the best solutions. An example of heat dissipation where passive cooling is supplemented with environmental airflow could help increase efficiency but would not cause excessive expense.

Taking into consideration the advantages and disadvantages of different methods helps develop a customized cooling plan that protects the SFP modules and maintains a stable network.

Why Does Cabinet and Rack Layout Matter for SFP Heat Management and How to Optimize It?

The arrangement of network equipment inside cabinets and racks has a significant effect on heat management as well. A poor arrangement can trap heat much like having a room full of people can restrict airflow, allowing the temperature to continually rise and the SFP modules to heat up.

Proper data center cabinet/rack layout takes airflow into consideration. The design of cold and hot aisles provides a means to separate the cool intake air and the warm exhaust air, avoiding any mixing between the two. Likewise, hot air is channeled from the cool air directly to the fronts of the equipment, which assists in efficiently cooling the equipment.

Cable management plays into this as well. Untidy cables or too many cables can block airflow and essentially act like a blanket around the SFP modules, causing additional heat to be trapped. A well-managed cabling system can improve airflow and ventilation if the manager is mounted either vertically or horizontally.

Adequate layout involves practicing the following:

- Location of high-power devices in regions with better airflow

- Avoiding overcrowding of network equipment by providing some space (when possible) between racks

- Providing vents or perforated doors to allow more adequate heat escape

By properly cooling your network equipment and being strategic about cabinet design, you can help keep the SFPs at a safer temperature. This will help achieve longer module life and more consistent network performance, while also minimizing thermal stress.

Taking the time to adequately plan the layout of the cabinets will ultimately provide a better foundation for your entire cooling effort, making temperature control more predictable and efficient.

How to Select Low-Power or Industrial-Grade SFP Modules to Minimize Heat from the Start?

Starting with a proper SFP module directly impacts the heat generated and the overall stability of the network connection. There are a few DRST options available—low power SFP modules and industrial grade SFP modules.

Low-power SFP modules are essentially efficiency-focused. A low power SFP module functions similarly to hybrid cars and their fuel consumption—they consume less electrical energy and produce heat accordingly. For example, power consumption for common low-power options is roughly between 0.5 and 1 watt, while a typical SFP module tends to be 1.5 watts or more.

Industrial SFP modules emphasize durability, longevity, and temperature tolerance. The environmental conditions remain extreme; however, there are SFP modules that can operate under conditions such as a wider temperature range of -40°C to 85°C.

When creating an SFP selection, I would commit to including:

- Power Consumption—Active power consumption: the less, the better; generally less heat and cost of cooling.

- Temperature Range—The greater the range, the better; generally refers to industrial extremes.

- Reliability—Reliability depends on the manufacturer’s reputation, but industrial modules tend to have stricter testing as well.

To reduce heat generation at the source, searching for low-power and industrial-grade SFPs is a good way to balance efficiency and durability. This decision to select low power or industrial-grade SFP modules is a significant contributor toward reducing thermal stress at the source, which will in turn contribute to the optical module’s longevity and sustainability.

What Are the Common Mistakes Leading to SFP Overheating and How to Avoid Them?

In many situations, overheating is the result of simple mistakes during the installation and maintenance of networking equipment. Overlooking such mistakes can lead to catastrophic damage. On the other hand, if we recognize them, we can help prevent problems before they occur.

Mistakes:

- Improper Installation: Forcing SFP modules into place or placing them incorrectly causes the heat paths not to work properly and can ruin the contacts. Because SFP modules require proper alignment, every time we align the modules, it allows better heat transfer and signal quality.

- Forgetting to Properly Ventilate: Forcing devices into tight spaces or blocking the device’s air vents causes heat to become trapped and may result in overheating. Just like covering a radiator prevents it from heating the room, blocking SFP airflow causes problems.

- Not Cleaning: Dust is an insulator. Dust builds up inside devices and blankets SFP modules and cages, keeping heat from escaping the device. Cleaning regularly should be the priority to help cool performance over time.

Solutions:

- Rigorously follow the manufacturer’s directions on SFP maintenance best practices.

- Organizations should have a designated place for networking equipment to help with airflow.

- Schedule regular inspections and clean any dust off the SFP modules and fans.

- Utilize temperature monitoring tools to help detect any overheating prior to an SFP failure.

Avoiding these mistakes is beneficial to preventing overheating, as it will prolong the life of the SFP module and ensure stable performance of networking equipment. Simple care and routines support a cooler, healthier operating temperature for your mission-critical components.

How to Conduct Temperature Monitoring Tests to Verify Cooling Solutions Effectiveness?

To evaluate if cooling solutions are effective, we conduct a few basic thermal tests by measuring temperature before and after cooling has been applied. This process verifies that any investment in cooling will provide positive benefits.

These temperature measurements can be taken using any accurate tools such as digital thermometers, thermal cameras, or Digital Optical Monitoring (DOM) sensors located on the SFP modules. These temperature measuring devices will provide accurate temperature readings at the location of the SFP modules.

When you design a testing method, you should specify a clear order to follow: record the baseline (before using cooling) temperature readings during the normal operating network load; then apply the cooling solution (fan, heat sink, airflow, etc.); and finally record the temperatures again either for a time period or after the ambient temperature changes.

Besides just the measured temperatures, you should also record environmental factors (room temperature and humidity). Knowing these factors provides additional context and can provide greater accuracy to the cooling effectiveness evaluation.

Document your findings in a logical way such as with graphs or in a visual way such as using temperature in a tabulated form. A successful cooling application will usually show temperatures a degree or two lower than some historical data collected earlier. You should see a reduction in thermal stress on the current SFPs.

Points to consider for a successful SFP temperature test:

- Use consistent measurement tools and methods before and after;

- Make the test realistic (under the same load) with meaningful results;

- Record environmental or other monitoring as appropriate (room temperature, humidity, etc.);

- Most importantly, repeat the test periodically to validate sustained cooling performance.

Using consistent temperature monitoring tests will help you rationally measure the effectiveness of your cooling efforts, protecting your equipment and controlling network operation. Providing a more robust sense of decision making isn’t just based on assumption, but evidence.

Conclusion

Managing SFP temperature is crucial in maintaining a stable, reliable network. Evaluate your network environment to determine what causes heat and recognize the signs of high temperatures. Implement real-time temperature monitoring systems (DOM, SNMP) to stay ahead of issues. Determine cooling solutions appropriate to the size of your network and improve the airflow in your cabinets. Regular maintenance (cleaning, installing the optical modules properly) will also decrease the risks associated with overheating.

Creating a thermal-safe environment for your optical module will give it a longer lifespan and decrease your risk of potential downtime. Ultimately, by managing the temperature of your SFP, you will turn a hazard into a manageable reality and maintain the performance of your network.

Reference Sources

- Cisco Systems – Networking Hardware Documentation

Temperature and Power Monitoring for SFP DOMs - Schneider Electric – Data Center Cooling Solutions

Data center cooling solutions - Intel – SFP Module Specifications

Intel E1GSFPBXU Compatible 1000BASE-BX SFP BiDi Module - Juniper Networks – Official Documentation

ACX7020 Network Cable and Transceiver Planning