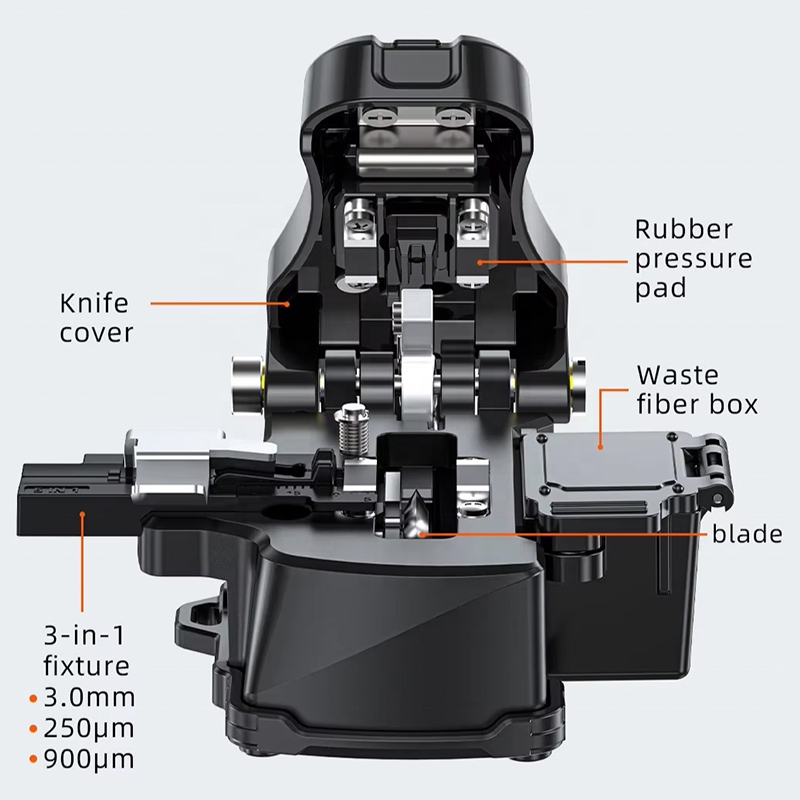

Tumtec A3 Fiber Optic Cleaver is also referred to as a Fiber Cutter with High Precision. The Tumtec A3 Cleaver features engineering precision combined with simplicity of operation, providing exceptional end face quality for Hot Fusion applications and Mechanical Splicing. It is specifically designed for Fiber to the Home (FTTH), Data Centers, and Lab applications.

High Precision, Durable Engineering

The Tumtec A3 Cleaver is manufactured from Tungsten Steel Blades with Multi-Layer Thermal Hardening and Fine Grinding. Each blade has 24 cutting surfaces and can cut up to 50,000 times, providing clean and consistent cuts. The average cutting angle of 0.3° results in a smoother end face, which reduces splice loss. The aerospace-grade aluminum alloy body provides the tool with lightweight and high durability. The tool allows for extensive use and can sustain accidental drops without compromising accuracy.

The 2-meter drop test on the Tumtec A3 Cleaver has demonstrated an average blade angle deviation of 0.3° after the drop and simulates the normal operational stress of ten thousand times. Data for drop testing of the Tumtec A3 is based on tests conducted at BYXGD laboratories. The actual results may vary slightly depending on the environmental conditions and usage habits.

Streamlined Operation with Automatic Blade Return

A3 incorporates a blade return mechanism, which enables operators to execute their cuts in a seamless manner on an ongoing basis. When the cutting is completed, the blade will reposition itself automatically to its starting position without requiring any additional movement from the operator. This feature is valuable for mass fiber termination applications. Additionally, A3 incorporates a blade height adjustment feature, so that operators can adjust the height of the blade throughout its entire lifetime to provide consistent and accurate cuts over time.

To adjust the blade height:

Loosen the fix screw.

Adjust the height of the blade by turning the adjust screw clockwise to raise the blade height; turning the adjust screw counterclockwise to lower the blade height.

Once you have set the height of the blade, re-tighten the fix screw to the current position and keep it locked in place.

As a result, you now have a cutting tool that will serve you well for several years and provide stable cutting performance for multiple fiber construction sizes.

5-in-1 Universal Fiber Holder

Three strands of protection are included for multi-mode and single-mode versions of the 4:5 Fiber Optic Connector, which include the following connectors:

• 3.0 mm drop cable

• 900 μm tight-buffered fibers

• 250 μm coated fibers

• 125 μm bare fibers

• Pigtails and patch cords

By allowing multiple fiber types to be processed without the need to switch holders, the 5-in-1 fixture results in substantial time savings and increased productivity for the end user by simplifying processes, improving cutting accuracy, and creating workflow efficiencies.

Technical Design and Anti-Damage Construction

Using a soft rubber compression pad, the Tumtec A3 reduces the chance of fiber breakage caused by uneven pressure or cold weather effects. It has a base that does not slip on uneven surfaces, adding to its stability. The fiber scrap box built into the A3 collects debris, keeping workspaces free of clutter and creating a safer environment for technicians working in confined areas such as distribution boxes or clean labs.

Reliable and Repeatable Cutting Performance

A clean cut that is perpendicular to the fiber axis is essential for minimizing splice loss. The Tumtec A3 provides a consistently clean, perpendicular fiber surface with every cut. Testing has shown that even after extensive use and multiple drops, the A3 maintains cutting accuracy within approximately 0.3°, demonstrating the precision and stability of the tool’s mechanical components. Due to the high level of consistency offered by the Tumtec A3, it can be used by teams performing repeat fiber terminations or by technicians requiring tight control over each operating procedure.

Maintenance Made Simple

The Tumtec A3 is a low-maintenance device. It comes with a hex key and cleaning brush for simple maintenance. Regularly cleaning the fibers on the pressure plate and the cutting surface helps eliminate any debris and maintain optimal functioning of the cutter.

If you notice a rough or inconsistent cutting edge, ensure the following:

That the fiber is correctly aligned in the Fiberglass Holder;

That the blades and clamps are clean;

That the height of the blade is properly adjusted.

By following these three simple procedures, you can ensure long-term cut quality and maximum cutting efficiency from your Tumtec A3.

Who Should Use the Tumtec A3?

The Tumtec A3 is ideal for FTTH or FTTx installs and maintenance, Data Centre Optical Cabling, Telecoms, Network Service Providers, Laboratory Fiber Testing, and R&D. Its compact and durable design makes it easy for any field engineer or lab technician who requires an efficient and reliable cutting tool with repeatable accuracy.

Complete Package

Each Tumtec A3 set includes the following:

- Tumtec A3 Fiber Optic Cleaver

- 5-in-1 Universal Fiber Holder

- Protective carrying case

- Cleaning brush

- Hex wrench

- Instruction manual

- Product box

Everything required to start precise fiber cutting is included right out of the box.

Technical Specifications

| Specification | Details |

| Model | Tumtec A3 (5-in-1 Fixture) |

| Product Type | Fiber Optic Cleaver / Fiber Cutter |

| Blade Material | Tungsten Steel |

| Blade Cutting Surfaces | 24 |

| Blade Lifespan | Up to 50,000 cuts |

| Cutting Angle | Approx. 0.3° |

| Coating Diameter | 0.25 mm & 0.9 mm |

| Cladding Diameter | 125 μm |

| Cleave Length | 9–16 mm |

| Applicable Fibers | FTTH drop cable, pigtail, jumper, bare fiber |

| Fiber Holder | 5-in-1 Universal Clamp |

| Automatic Blade Return | Yes |

| Anti-Fiber Bounce Design | Yes |

| Waste Fiber Collector | Yes |

| Body Material | Aluminum Alloy |

| Product Weight | 0.18 kg |

| Dimensions (W × D × H) | 78 × 89 × 56 mm |

| Package Weight | 0.3 kg |

| Package Dimensions | 120 × 107 × 66 mm |

| Place of Origin | Guangdong, China |

| Brand | Tumtec |

Designed for performance and reliability, the Tumtec A3 Fiber Cleaver’s superior quality is the result of a combination of components, including the solid aluminum construction and the adjustable precision mechanics of the cleaver, which provide exceptionally precise cutting results over thousands of operations with a single blade made from tungsten steel.

The cleaver maintains consistent cutting accuracy (~0.3 degrees) following impacts from drops and extended use in the field (as shown in laboratory test results by BYXGD). However, actual performance may vary significantly depending on environmental conditions.

The Tumtec A3 will prove equally effective as a fiber cutter for fiber installation, fiber maintenance, and laboratory work. Thus, it is one of the most respected fiber-based cleaving tools readily available in the market today.

Reviews

Clear filtersThere are no reviews yet.