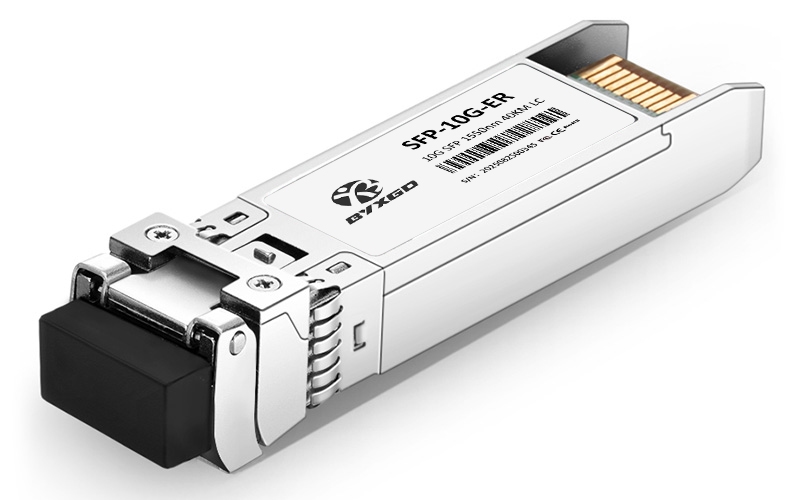

SFP+ SR, LR, and ER Modules: Your Definitive Guide to Choosing and Deploying 10G Fiber Optics

High-speed data transmission in enterprise and data center networks is driven by 10G optical modules. Choosing the proper SFP+ module, whether it be SR, LR, or ER, can have significant impacts on performance, reliability, and costs. Knowing the key differences, compatible fiber types, and correct use cases can help you avoid making a costly mistake by getting the wrong one and fewer deployment headaches. This guide will break it down, giving you some usable tools to use for improving your network infrastructure.

Understanding SFP+ SR, LR, and ER: Parameters and Distances

SFP+ SR, LR, and ER modules are the cornerstone of 10G fiber optic networking. Each module is designed for a specific link distance and fiber type. Understanding the basic differences between each module is important to prevent an expensive misconfiguration and provide you with the best network design. The differences are primarily based on operational wavelength, compatible fiber media, and maximum distance.

What Are the Fundamental Distinctions Between SR, LR, and ER Modules?

SR (Short Reach) modules utilize a wavelength of 850nm and only function over multimode fiber (OM3 or OM4), delivering reliable data transmission at approximately 300 to 400 meter distances. They are well suited for intra-building or data center connectivity, where the fiber path is confined to a short distance.

LR (Long Reach) modules operate with a wavelength of 1310nm and require single-mode fiber to extend the effective distance to roughly 10 km. This is adequate to cover campus backbones or metropolitan network traverses.

ER (Extended Reach) modules perform a 1550nm wavelength transmission over single-mode fiber and can extend distances beyond 40 km. They support long-haul applications and are suitable for linking buildings or other regional applications.

When selecting modules and using distances or fiber types outside the specifications, signal errors and degraded throughput will occur, resulting in a possible link failure. Once you understand and review these basic differences, you can select modules practically and effectively without errors.

Why Does Fiber Type Matter? Multimode vs. Singlemode Explained

The type of fiber optic cable will directly impact the compatibility of a module and the overall performance of a network.

- Multimode fiber (OM3/OM4) has a larger core size, allowing multiple modes of light; however, the distance is limited due to modal dispersion experienced with multimode fiber, and so SR modules will be used exclusively.

- Single-mode fiber has a smaller core size, which allows the propagation of a single mode of light and is able to support larger distances to LR and ER modules.

If a single-mode module is used with multimode fiber or vice versa, the signal quality will be very poor or there will be no connectivity. If the fiber quality degrades or the cable ages, this will further limit performance. So, confirmation of the integrity of the fiber type is important prior to making a module selection.

How Do Leading 10G Modules Compare? Exclusive Detailed Head-to-Head Analysis

Below is a succinct comparison of some of the more recognized 10G SFP+ optical modules to demonstrate variances:

- Cisco GLC-10G-SR – The SR model, working at 850nm, with multimode fiber, has a maximum reach of 300m and is generally employed in data centers.

- Finisar’s FTLX8571D3BCL – is comparable to Cisco’s GLC-10G-SR module with DDM, the same parameters operate at 850nm, with multimode fiber; however, it has a reach of up to 400m.

- Cisco GLC-10G-LR – The LR model works at 1310nm with single-mode fiber, the maximum distance is 10km. The LR model is generally utilized as the campus backbone network.

- Juniper EX-SFP-10GE-LR – This is also an LR model with a 10km reach on single-mode fiber. This part is certified for Juniper switches.

- Finisar’s FTLX1471D3BTL ER, is rated at 1550nm over single-mode fiber, with an achievable range to 40 kilometers and acceptable in many long-haul applications.

The comparison presented provides some guidance to clarify module performance at a glance. Obviously, it may help network professionals to quickly understand performance differences and better prepare you for any upcoming planning or purchasing decisions regarding sections of any networks. Users, professionals, the overview provided will support your life cycle decision-making.

How to Choose the Right SFP+ Module Based on Network Distance and Application

Selecting the right SFP+ module depends on several factors, but you want to be most aware of the physical layout of your network and the type of fiber you’re running. For shorter links, typically under 300 meters and running on OM3 multimode fiber, SR modules are the most cost-effective option. For longer links under 10 kilometers, where you still need an SFP+, you will need LR modules.

LR modules will require you to have single-mode fiber to maintain the signal integrity. Over shorter links, like in inter-building connections of over 10 kilometers, you will want to utilize ER modules. By properly selecting your module to fit your specific distance and fiber type, you will get better performance, fewer errors, and hopefully just more money you could have spent on features you did not need.

It is about weighing the cost against the performance; for example, don’t buy longer-range modules for short runs…the LR/ER modules typically cost more and consume more power. Choosing modules to fit your specific environment protects your network investment.

How Did a Data Center Optimize Performance Using SR, LR, and ER Modules? Case Study

A large data center was experiencing intermittent latency spikes and frequent link resets on backbone connections. They had originally deployed their network using primarily SR modules and could see no clear rationale as to why some links were not stable on longer runs. The team performed a site audit of their fiber infrastructure and made the following strategic deployments of SFP+ modules:

- SR modules were retained for short intra-rack and nearby rack connections.

- LR modules were swapped in for SR modules on mid-range (up to 150 meters) campus backbone fiber.

- ER modules were used for the longest inter-building fiber routes, which proved to be too far for reliable LR connections.

Using the multi-tiered SFP+ module approach to managing the impact of different link distances reduced latency by 25% and cut network downtime by half. The ensuing reduction in operational costs was 15%, which also stemmed from optimizing power consumption and fewer SFP+ replacements needed. This deployment was successful because it indicates that the characteristics of the link distance should dictate the SFP+ modules chosen for deployment and not a simple default assumption.

Why Is Compatibility Vital? How to Avoid Costly Mistakes

Compatibility between SFP+ modules and associated equipment is a critical factor in link reliability. Using modules that are not certified by the original equipment manufacturer (OEM) or, more importantly, ignoring the EEPROM coding standards can lead to unrecognized transceivers, intermittent connectivity issues, or worse, performance degradation.

These are significant issues that can affect your network’s operation. These types of issues can also lead to expensive troubleshooting and replacement, wiping out any savings you might have achieved by purchasing cheaper, uncertified modules. Industry-grade equipment must have appropriate transceiver support in device firmware, in the physical port being used, and most importantly for tracking purposes, EEPROM identification. Compatibility should always be at the forefront of your mind for obtaining stable, long-lasting network links.

What Are the Essential Compatibility Checks Before Purchase? Pre-Purchase Checklist

To avoid discrepancies that could affect hardware compatibility, please refer to this checklist:

- Verify your switch or router has an approved SFP+ module list.

- Ensure the EEPROM codes of any proposed modules match the expected codes.

- Confirm your firmware can support the modules you have selected for implementation.

- Validate that your modules and equipment share compatible fiber types and connector standards.

- Only purchase from authorized dealers or the manufacturer to mitigate issues with counterfeit products.

- Examine the stated power consumption and thermal capabilities of your modules to confirm they are acceptable for your environment.

Following this checklist should ease your mind and create less risk as you deploy modules to your network systems; it should also put you at ease regarding your choices as you continue as a network professional.

How to Ensure Flawless Installation and Maintenance of SFP+ Modules

The first step to a reliable network is to make sure that your installation is done correctly. Cleaning the fiber end faces is the first step. Make sure that you are removing dust and other contaminants that negatively affect the quality of the signal. Place the SFP+ module into the port carefully but firmly until it clicks into place. Don’t force it. It is better to remove it and do it a second time to avoid damaging it.

Make sure that you are using the appropriate type of SFP+ module for the environment that you are deploying into. A commercial-grade module is adequate if it will be installed in a data center. However, if the module will be deployed outdoors or in an extreme environment, it is best to go with an industrial-rated module that has a wider temperature range.

In terms of preventative maintenance, periodically check to ensure that the fiber connections are secure and clean the connectors on a regular basis. Most modules have a built-in diagnostic tool that will assist you with monitoring the health of the module. Following a consistent routine with these items will minimize unplanned outages and prolong the life of your optics.

How to Troubleshoot Common Issues Like Signal Loss or No Link Using CLI

A systematic troubleshooting approach can quickly lead to discovering the root cause of problems like signal loss or no link. No link can be caused by several things, such as improperly seated modules, dirty connectors, or not using compatible modules. High error rate is often an indication of physical fiber damage or a problem related to power level.

CLI commands can be useful to find out information: On Cisco devices, enter show interfaces transceiver detail to see Tx/Rx power, temperature, and voltage. On Juniper routers, run show interfaces diagnostics optics for similar data.

When analyzing the output, you will find that low Rx power is usually a good sign of either dirty or compromised fibers. You will also see that abnormal Tx power means that the module might be faulty. You might also check the temperature if there is hardware stress or if it is out of temperature specifications. This will speed up the process of diagnosis, which means faster resolutions to issues and ultimately more uptime.

What’s Next After 10G? Future Trends in SR, LR, and ER Optical Modules

The advancement beyond the 10G SR, LR, and ER modules is a response to bandwidth demands and increased data rates. The new 25G, 50G, and 100G SR/LR/ER modules will all use the same fiber types and wavelengths as their counterparts, ensuring backward compatibility. In addition to being faster than their predecessors, this new technology will provide additional diagnostics and increased efficiency, allowing users to upgrade network hardware without having to replace cabling.

An understanding of this evolution will prepare the network professionals of the future to make system upgrades fluidly, while also educating their business leaders to make budgeting decisions that optimize efficiency and growth, and contain costs.

What Is Your Final Checklist for a Successful SFP+ Module Deployment?

The successful deployment of the 10G SFP+ SR, LR, and ER modules is contingent on a few key steps you’ll want to take. The first step is to properly match each module to the link distance and fiber type. Use an SR for short multimode runs, LR for short single-mode runs, and an ER for long-distance multimode runs.

The second step is to ensure that you’re using vendor-certified modules and to review the EEPROM codes to verify compatibility. If you skip this step, the link can fail. The third step is to follow proper installation practices. This means cleaning the connectors, firmly seating the modules, and of course, ensuring that you’re installing the equipment within the manufacturer’s environmental specifications.

The final step is to regularly monitor and diagnose the health of your network and clean your fiber as required. By doing this, you can prevent degradation of performance and unplanned downtime. This checklist provides a clear and consistent methodology for effective, low-cost network upgrades.

What Are Your Top FAQs on 10G SFP+ SR, LR, and ER Modules?

- What is the maximum distance you can transmit data with 10GBASE SR? Normally, you can reach roughly 300-400 meters with OM3 or OM4 multimode fiber.

- Can I use SFP+ LR modules on multimode fiber? No; you have to use single-mode fiber with LR modules, or the signal will experience integrity issues.

- How do I find the right module from the part number? Review the vendor specs for identifiers or details on the module, and look for identifiable information about “SR,” “LR” (or a variation), as well as the wavelength and fiber type.

- What things can contribute to signal degradation at the link layer? Physical damage to the fiber, dirt or oil on the connector, incorrect pairing of the module with fiber, and old cable.

- How do I verify that the module will be compatible with my current switches? Check the vendor list of devices, compare the EEPROM code on the module to the code of the devices, and if possible, test the modules before you deploy large quantities.

Are there third-party SFP+ modules that are reliable and less expensive than buying ‘OEM’ SFP+ modules directly from the vendor? Some third-party modules can be cheaper, but higher rates of failure may occur at the same time. Third-party suppliers may not provide the same support as the device vendor after the sale, so the reliability of third-party modules can sometimes be a gamble.