SFP Safe Plug-and-Play Ultimate Guide: Operation Procedures to Hardware Damage Prevention

SFP modules require a high level of care and precision, as they perform a very important function for your network, and anything done improperly can cause damage to hardware, costly downtime, or negatively impact the performance of the network. We are all familiar with some of the risks faced when handling SFP modules, including bent connectors, static discharge, and dust contamination, which can all negatively impact reliability.

By understanding how to safely and properly install and remove SFPs, you can prevent these problems and extend the life of your equipment. Following safe procedures for the installation and removal of SFP modules will make your life easier and help to increase your network uptime. A reliable set of procedures that breaks down the process step by step will allow you to stay organized and help things run smoothly.

Knowing how to perform these important steps for SFPs will reduce failures caused by mishandling and provide a more stable, efficient network environment.

What Makes SFP Safe Handling the First Line of Defense for Network Stability?

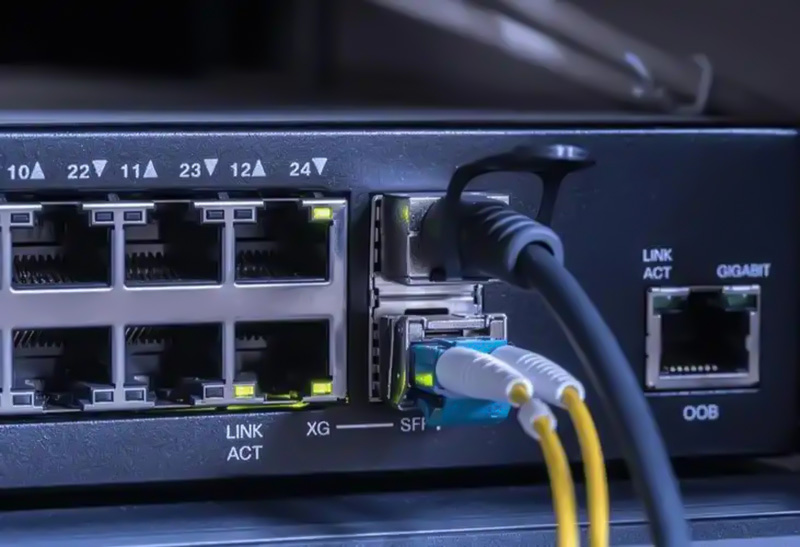

Safely handling SFP modules is akin to having a bouncer look after your network to avoid damaging your hardware, which in turn will create unexpected downtime. If the SFP module is physically misaligned in the SFP port, then the sensitive plastic connectors inside the SFP module can become bent or break. If the SFP module is pushed in incorrectly or twisted, then the gold fingers that carry the signals may become damaged or misaligned, eventually leading to poor connectivity or a complete failure of the connection.

Why does this matter? We have all experienced hardware being destroyed because of careless or improper handling, which leads to unplanned network outages. When the SFP is stuck or broken, data transmission halts and all devices connected to that SFP lose a route for communication. Fixing a broken SFP will include costs associated with replacement and possibly lead time for repairs, which equals loss of time and money spent on repairs that affect critical operations.

Safe handling procedures of SFP modules and ports follow the same principles, recognizing that movements during insertion and removal must avoid excessive force or twisting. Always inserting aligned is key; alignment, insertion process, and removal are all key attributes to avoiding hardware challenges. A safe process for inserting or removing an SFP should also include always putting on clean, dust-free gloves. You have now minimized the chances of contaminating the connectors inside the SFP module and the ports that the SFP module connects to.

Now, with all of these tools to ensure the safe handling of the SFP module, we can confidently state that safe SFP insertion or removal has transformed from an action to a practice of prevention. Safe handling protects the health of the module but also the overall health of the network itself. Any mistake while handling an SFP module exposes single points of failure that escalate into very serious operational shortcomings.

In conclusion, awareness of the safe handling of your SFP will lead to deliberate consideration every time you install or remove one. A deliberate consideration during every SFP installation or removal will minimize the possibility of hardware damage and ensure you get maximum lifetime of equipment to support the network’s stability. Safe handling of the SFP module is the very first and best form of defense to avoid hardware damage and continued network outages.

How Does Preparing Tools and Environment Ensure a Flawless SFP Operation?

Before we start installing an SFP module, we prepare the right environment and tools to be used, like preparing a clean workspace before cooking a meal. Proper preparation can often help prevent problems that could be hidden and lead to damage once something is handled.

An antistatic wrist strap is an important part of the whole process to prevent electrostatic discharges (ESDs). Even a small static shock can fry circuits on these sensitive transceiver chips, leading to failures either right away or later in the future. The antistatic wrist strap will ground you to prevent static electricity from transferring to either the SFP module or the network device itself.

Cleaning supplies are just as important to the preparation. Dust and dirt particles may not seem harmful when you examine them, but they are extremely harmful when it comes to fiber optic connectivity. Cleaning supplies should include lint-free cloths and a cleaning solution that does not have alcohol on the label. Cleaning the ends of the fiber optic connections and the surface of the SFP module is essential to removing dust and dirt particles that can degrade the transmission signal.

Dust-free and static-free environments create a protective bubble. Dust particles can settle inside ports and create micro-interruptions. Static triggers occur without physically seeing something happen to the SFP module or network device, but they can cause irreversible damage to either. If you can conduct any installation or uninstallation in a completely clean, dust-free, and static-free environment, the risks of damaging photo-transistor connections and optical signal transmission reduction of both the SFP module and network device are significantly reduced.

Some conversation starters about getting ready to install SFP modules are:

- Have an antistatic wrist strap on and fastened to a grounded object.

- Clean the ends of the fiber optics and ports before inserting the module.

- Keep the work area free of dust by using air blowers or clean air cabinets.

- Avoid being near the equipment while wearing any synthetic fabrics or materials, as additives and synthetic fibers can generate static.

Following a few of these basic start-up preparations will allow SFP module installations to be seamless without any surprises. The combination of proper tools and the right environment creates a safety blanket that is effective and prevents both visible damages and invisible failures.

Being solidly prepared is one main step toward preserving the integrity of the module’s onboarding and ongoing network performance metrics. It will create a safe location for delicate components as well as ensure the installation and uninstallation process goes smoothly from start to finish.

How to Install Your SFP Module Perfectly Every Time

Installing an SFP module is like putting together a puzzle: you have to be sure the connectivity aligns perfectly for everything to slide into place smoothly. Following these five simple steps ensures a reliable connection and secure connection to be fully operational for the longevity of your device and the module.

Step 1: Run a visual inspection of the module and the port

First, you should inspect the module and the port for dust or debris. If either the module or port shows evidence of dirt, you can gently rub it to remove the dirt. Always be cautious when you are cleaning dirt off the connectors, as it can easily scratch the delicate surface; dirt on either the module or port can block connections.

Step 2: Align the module as needed

Next, you should be sure to align the module connector with the port slots correctly. Visualize sliding a card into a reader; it shouldn’t be tilted, it has to fit straight in. Always be cautious about inserting the module at an angle instead of straight, as this can cause the gold fingers to bend and cause damage.

Step 3: Insert the module firmly and gently

Once aligned properly, push the module straight into the port until it completely sits. You do not want to apply a significant amount of pressure to make contact; this can easily break a connector. It also needs to be noticeable that there is contact, but not too little that it does not connect at all.

Step 4: Listen and feel the click

The click sound from the latch confirms the module is secure and in place as expected. Hearing this should give you peace of mind that the module will not loosen while you are using it to connect to the appropriate network or device.

Step 5: Verify the module has been installed

Lastly, whether it is through a device status LED on the device or a management interface, confirm the SFP module has been installed correctly and that the device will recognize the newly installed SFP module.

Avoiding Insertion Angle Errors

A small angle when inserting can bend gold fingers, which can disrupt the signal. Think of trying to insert a plug upside down. It is important to stay with the correct angle. Getting the SFP module at the right angle allows you to avoid damaging your equipment and making bad connections.

Following this SFP installation step-by-step method helps you ensure you are installing the module safely without worry. If you continue to do this consistently, you can maintain a good working network and keep your equipment functioning longer.

How to Remove an SFP Module Safely Without Causing Hardware Damage

When removing an SFP module, do so carefully, taking care of the module and carefully removing it from the SFP port. Following the proper order will avoid any damage and will enable smoother removal.

- Power Down the Port (or Disable the Port)

At a minimum, you should turn OFF the port you plan to remove the SFP module from. Doing this minimizes possible electrical and data errors. I am always cautious when removing hardware and try to minimize potential risks. - Carefully Release the Latch

Once deactivated, locate the module’s latch or pull tab. You will either press down or pull the tab upwards gently to unlock the SFP module. You don’t want to apply too much force and break the latch release mechanism. - Pull Module Straight Out

Once unlocked, pull the module entirely straight out of the SFP port and keep the pull path as straight as possible (without twisting or pulling upwards or downwards). Think about pulling it out the same way you open and close a drawer—straight motion is how to properly withdraw the module without damaging the connectors. - Assess Module & Port

Take a moment to assess the module and the socket. Look for any damage and remove any debris or obstruction to maintain optimal connectivity.

What to do when a module is stuck from removal?

If, after following the steps above, the SFP module remains “stuck,” do not apply heavy force. Once again, make sure the latch has not engaged another notch. If you can easily separate the latch, you might try applying a small amount of isopropyl alcohol on the latch mechanism. You could also try slightly wiggling as you pull straight out of the module at the same time, but do not twist too strongly, as there may be components in the way of straight removal.

Being patient and taking your time to follow the steps will minimize the risk of overly damaging the hardware SFP module during removal. It is a valuable investment, and you do not want to add either to your IT costs or inhibit your business productivity by downing network hardware.

Correctly and safely removing the SFP module is just as important as properly installing the module. The approximation of these steps is required for care to maintain stability in the system. If you master the proper wording below, you should eliminate any costs associated with either damage or support for the general optimization and performance of a network.

What Real-life Lessons Can You Learn from a Network Crash Caused by SFP Mishandling?

A typical SFP troubleshooting involves a case where a client experienced a total outage of their entire network, the eventual cause was a result of improper handling of the SFP modules. This all began when the technician removed and reinstalled SFP modules out of order.

What happened? Instead of following the proper protocol, the technician removed the SFP modules while never disabling the ports and he removed some modules at an angle causing the gold fingers to bend. The technician either reinserted the modules that had already been removed back into the switch without cleaning, which may have added to the problems. The careless way to improve device communication caused some of the hardware to be damaged and the network would become unstable.

The immediate result: The network went down with cascading failures. There were link losses which caused failover loops, which added to the downtime. Devices were unable to communicate which blocked necessary services. The client faced significant costs due to the business disruptions created until repairs could be done.

Troubleshooting steps involved:

- Physical inspection confirmed damaged SFP modules and damaged SFP ports.

- Bent modules replaced and damaged ports repaired.

- All fiber connections were cleaned prior to reinstalling new modules.

- Device logs and firmware were reviewed to ensure no further issues would arise.

- Implemented safe handling procedures for future operations.

Lessons learned:

- Always disable the ports in the switch prior to removing the SFPs to prevent power signal issues in the switch.

- Be gentle with SFP modules, and observe alignment with the ports to minimize damage.

- Always clean connectors before inserting and reinstalling the module to create quality signals.

- Systematically follow all recommendations steps to preserve the health of hardware.

This case study shows how simple misuse can lead to an outage, and complex faults can emerge from a seemingly simple mishandling of the equipment. Following or referring to a safe handling guide for SFP modules is critical to the health of the hardware. Understanding our actions and mistakes will help the rest of our teams avoid both outages and costly repairs later.

How Can You Avoid Common SFP Handling Mistakes to Become a Pro?

Most SFP handling errors are the result of either a careless mistake or a poor habit and may cause drastic physical damage to your hardware. The most common SFP handling mistakes consist of too much force, lack of cleanliness, and not taking ESD precautions.

Too much force when inserting or removing the SFP is the number one cause of bent or broken gold fingers. If you have a fragile SIM card, you would never try to push that card too hard into the connector. You would damage the contacts — it is the same with the SFP. Gentle, even pressure removes the risk of costly physical damage.

While it may not seem serious to allow dust and oil to accumulate on connectors, this will impact your performance and your signal quality will degrade. It might be similar to trying to listen through a dirty window pane; you can hear the message, but not clearly. This is what the ends of your fiber optics are like if you do not clean them regularly. You use lint-free cloths to clean fiber connections, and alcohol-based cleaning solutions can also be effective in restoring signal quality.

ESD precautions are also frequently not taken as all SFP modules are likely exposed to silent electrical shock. Often, the static discharge can have a permanent effect on internal circuits. Wearing an antistatic wrist strap or admonishing staff to ground themselves before touching a module can avoid this risk involved in these electronic devices.

When you sense any of these or even a combination of mistakes, just don’t do it! You can rewire these mistakes and correct yourself by:

- Paying attention to your pressure during installation and removal

- Inspecting and cleaning your connectors before you plug them in, and on a regular schedule, as needed

- Always grounding yourself before you touch a module.

Be intentional about the above errors too, as a simple breakdown in the fiber optics may lead to damage to the hardware. If you pay attention to these common errors, you will have a successful prevention of damage to hardware, and SFP modules will last as long as they are able to, and your return policy is still valid. If you make a habit before and throughout each interaction of handling the SFP modules with caution, you can be confident in your handling experience, and you can maintain some level of stability in networking by handling SFP modules appropriately.

What Are the Best Practices for Daily Cleaning and Hardware Maintenance of SFP Modules?

Keeping SFP modules clean helps keep connections clear, preventing signal loss and extending the life of the module. In addition to the reliability aspect, using a lint-free cloth helps avoid scratching gold fingers and port surfaces, and using alcohol-free cleaning solutions will get rid of oils without damaging other surfaces.

Cleaning can be done safely – label each SFP when cleaning and take care to simply wipe the gold fingers in a gentle and straight motion rather than scrubbing. Cleaning the fiber optic ports with soft brushes or specialty swabs designed for cleaning AV equipment will help minimize the debris from cleaning so the tiny fibers stay unobstructed.

Static control is key for any electronic hardware maintenance. Explained simply, the static charge will build up in and around the module causing tiny sparks inside the module, degrading the component over time. To avoid this hidden hazard, use antistatic mats for the module and the work area when cleaning the modules, and use static wrist straps to ground you when performing maintenance.

Follow these practice guidelines:

- Use lint-free cloths and do not use abrasive materials

- Use alcohol-free or isopropyl cleaning solutions designed for electronics

- Clean ports and connectors regularly and prior to installation

- Ground yourself to eliminate the possibility of electrostatic discharge during maintenance

Consistent cleaning and static control to maintain the quality of signal parameters and performance will allow for optimal module performance. In our case of handling SFP modules, gentle assessments and cleaning with good hardware maintenance habits will increase network reliability over time. Reductions in repairs and costly downtime due to contamination or electrostatic discharge begin to melt away with best practices.

How Does Firmware and Compatibility Impact Your SFP Installation Success?

Confirming the equipment compatibility for both the firmware and SFP module is very important prior to installation of the module (just like confirming software fits the hardware in a computer). Ultimately, the firmware is what controls how the SFP module will perform in communication and must be compatible with the requirements of the network device.

Having incompatible firmware has the potential to cause the module to either fail or provide unreliable connections. An incompatible module may cause error messages to appear, which must be addressed, or ultimately may cause an unexpected reboot of the module or device, either of which interrupts the proper flow of data and could cause downtime.

The simulated test data is provided exclusively for evaluation to illustrate aspects of stability over the different configurations. For example, the modules that were running fully updated firmware were using equipment that provided compatibility specifications to the firmware; these items achieved the appropriate outcome with signal drops. The modules that had mismatched equipment had devices that unexpectedly lost connections and prompted hardware resets.

To ensure checked firmware and compatibility for proper performance:

- Static test all firmware to a manufacturer’s specifications.

- Use SFP modules that meet the manufacturer’s specifications.

- When firmware is being revised, update the versions.

If compatibility of the SFP module is ignored, it considerably endangers the network device’s operational stability in achieving configurations, which may even affect the service life of the module. If these checks are worth doing and taken seriously, when in place effectively, brand new equipment combinations will generally resolve multiple issues while providing a positive experience during installation. When potential issues are prevented, you will be sure to clearly avoid the hidden issues that can cause data integrity and availability to be eroded over time. A few testing equipment scenarios that were validated enabled combination resources to avoid checks per test avoidance and save time on installation and maintenance practices.

Conclusion

Being knowledgeable about the proper handling of SFPs is essential for the health of a network. Mindfully inserting and removing SFPs will save your organization unnecessary hardware grief, downtime, and repair bills. Ensuring proper handling will protect the investment in that SFP and allow data to flow uninterrupted.

By utilizing tried-and-true handling techniques, your day-to-day practice becomes a predictable and reliable operation. The experience, like a quality manual, will keep you safe while installing and removing modules, cleaning up the area, and performing troubleshooting.

As you become more expert in performing maintenance with your network, stay mindful. Commitment to gentle handling, preparation, and checking for compatibility will go a long way in sustaining a network’s integrity and performance over time.