RJ45 Interface Optical Module Guide: Selection Advice for Copper Cable Environment Compatibility

Network administrators encounter complications when adding RJ45 SFP modules during a transition from copper cabling to fiber optics. Organizations that need to maintain “backward” RJ45 support can feel overwhelmed by a host of modules and solutions that attempt to balance compatibility, price, and performance. Many network administrators lack the ability to carry forward their existing RJ45 cabling routing, which could include an office, closet, or floor environment, when upgrading. Copper SFP modules help organizations leverage an existing copper infrastructure, not only saving the cost of rewiring, but also continuing the ever-changing world of optical fiber. To learn about practical adapter solutions that enable flexible network designs integrating both copper and fiber, review our SFP+ to RJ45 Adapter Application Guide. It explains how to maintain legacy infrastructure while advancing to fiber.

It’s important for network administrators to understand the technical parameters around RJ45 networking: speed standards for RJ45, cable quality, and power utilization. An equally troubling issue lies in troubleshooting legacy compatibility issues with aging copper devices and addressing thermal management concerns in a high-density module deployment. The strategies for a copper-fiber network-facing integration experience are: selection of the most appropriate modules, the elimination of the case or problem, and planning for the future both for reliable applications and for cost efficiency.

What Are RJ45 SFP Modules and When Are They Essential?

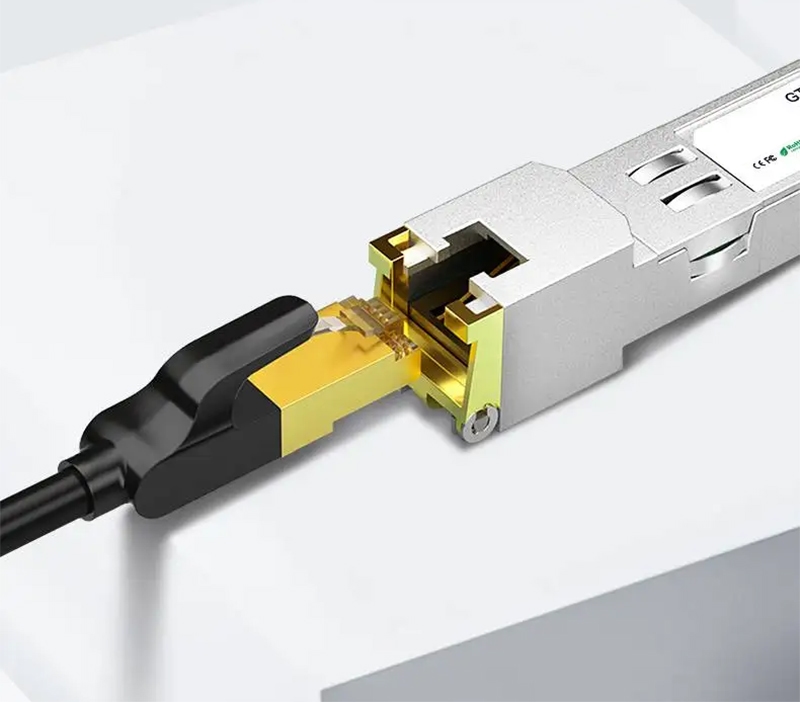

RJ45 SFP modules connect traditional copper Ethernet cables to SFP switch ports initially intended for fiber optic connections. Rather than transporting light signals like fiber modules do, these adapters convert the electrical signal transmission over copper medium. If we think of an analogy to the adapters we often use with our car, sometimes USB-C adapters, it is similar to a language adapter. Using an RJ45 SFP module allows us to keep using legacy copper data flows and push them into a newer optical hardware ecosystem.

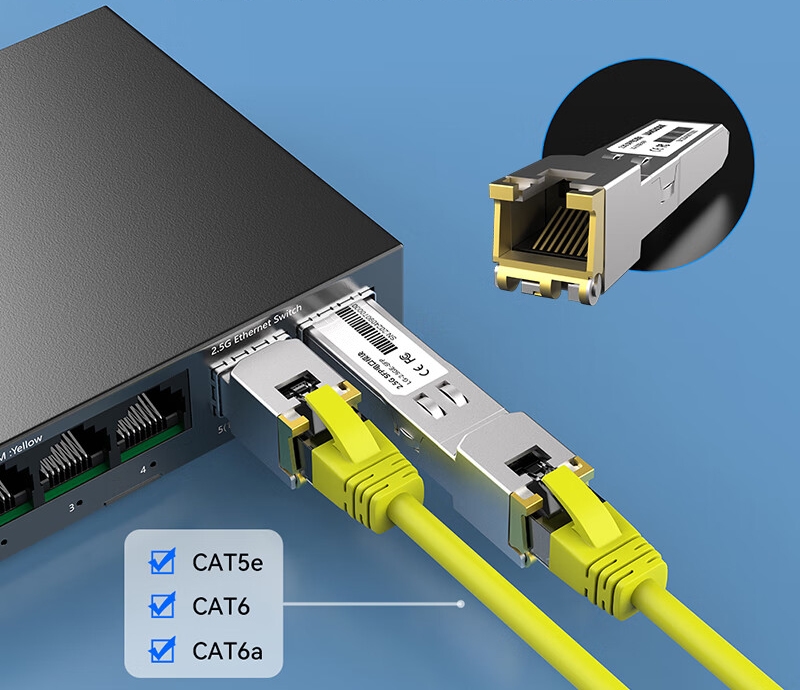

RJ45 SFP modules have an important use case for environments that rely heavily on Cat5e, Cat6, or Cat6A cabling. The square footage for cabling can become substantial quickly, so rather than replacing copper cabling, these modules will allow organizations to maintain the existing cabling while upgrading the switch hardware. For legacy copper cabling, these modules have an ideal use case in buildings or data centers where copper cabling dominates, dramatically reducing the initial costs of implementation by not having to perform a full cabling replacement.

The important aspect of an Ethernet cable using copper is that the copper transmits the electrical signal, which is much more susceptible to electromagnetic interference and limited in distance compared to fiber optics. Fiber optics can do long-distance, high-bandwidth, and noise-free transmission, which is a main reason why fiber optics is replacing copper cabling. Using copper optic modules will depend on the balance of existing constraints of the user’s infrastructure and performance of the user’s network. Understand the key distinctions between copper and fiber SFP modules, including transmission methods, performance, and cost factors, in our detailed Copper SFP vs Fiber SFP Modules guide.

Key Takeaways:

- RJ45 SFP modules will deploy electrical signaling in the SFP switch slot.

- RJ45 SFP modules are a cost-effective interface for legacy copper systems.

- Electrical signaling is limited by distance due to electromagnetic interference and noise transmission, whereas optical transmission is less affected.

The IT Manager’s $25K Infrastructure Dilemma: New Fiber Switches, Old Copper Cabling

The IT Manager’s $25K Infrastructure Dilemma: New Fiber Switches, Old Copper Cabling

A mid-sized company found themselves in a challenging position acquiring fiber switches as they had an installation of extensive legacy Cat6 copper cabling. Where they were to implement fiber optics, their install would result in replacing an expensive and time-consuming copper run, which could cost as much as $25,000 and easily delay the project.The solution presented itself through the use of RJ45 copper transceivers. These modules provide a plug-in to the new fiber switches that directly connect to their existing copper infrastructure, all but negating the need for newer and more expensive cabling, wiring, and terminations. This allowed the organization to maintain existing operational continuity and keep their hardware upgrades from being delayed.Copper SFP deployment allowed the crew to improve timelines by weeks and reduce costs. This approach allowed them to leverage existing cabling and reduce the cost overruns and downtimes associated with replacing existing cabling.

Comparison Table:

| Option | Cost Estimate | Deployment Time | Operational Impact |

| Full Copper Replacement | ~$25,000 | Several weeks | High disruption risk |

| RJ45 SFP Module Deployment | Significantly lower | Minimal | Continuous connectivity |

This scenario highlights copper transceiver deployment’s strategic advantage in fiber migration environments.

Why Power Consumption and Heat Management Matter More Than You Think

Copper RJ45 SFP modules have a much higher power draw than their fiber optic counterparts. Fiber modules send signals over photonics and have much lower electrical consumption. Sending signals via electricity over copper requires more power, which can impact switch power design and operational costs. High-density installations can make thermal issues even more complicated to manage. The higher number of RJ45 SFPs installed in a switch chassis will produce excess thermal energy, which heat sinks, fans, or optimal airflow can relieve. Unfortunately, without good thermal management, the excess thermal energy can limit the reliability and life of the device. Network engineers and architects need to calculate power and thermal budgets by summing the number of modules and their per-module consumption for a deployment. That means determining the maximum number of copper SFPs that will fit in the chassis and designing the cooling systems that will meet specifications. For comprehensive strategies to manage power, thermal challenges, and optimized deployment of RJ45 SFPs, explore the Ultimate Guide to SFP to RJ45 Adapter.

To superimpose the critical imperatives:

- Copper RJ45 modules will have a higher power load because they are sending signals through electricity.

- Thermal management is necessary for the stability of high-density configurations.

- Power load calculations help inform the appropriate thermal infrastructure to specify the heat limit of the copper SFPs.

How to Select the Right RJ45 SFP Module for Your Network Requirements?

How to Select the Right RJ45 SFP Module for Your Network Requirements?

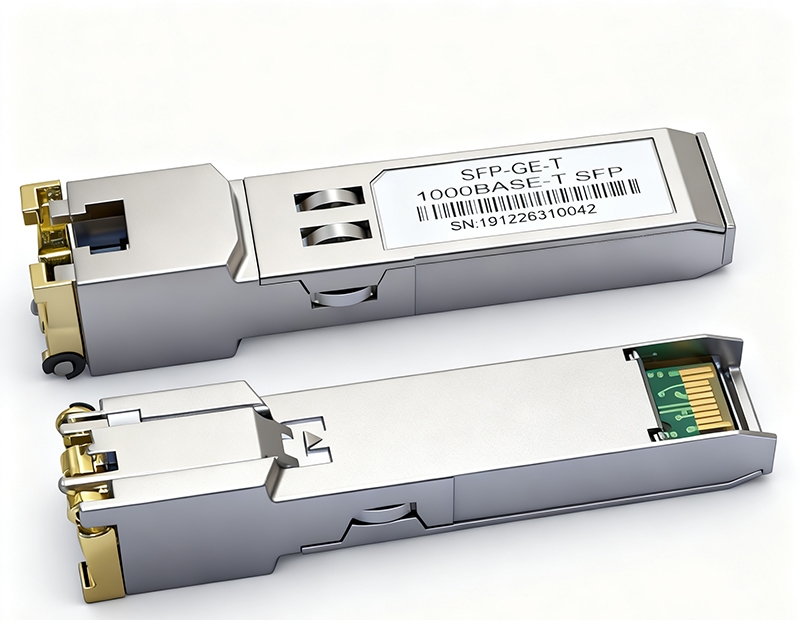

When selecting an RJ45 SFP module, it’s essential to stay within the particular network hardware and cable environment. While you want everything to work correctly, the most important thing to get right is speed. Standards are 1000BASE-T for gigabit Ethernet, and that is where things become ambiguous; 10GBASE-T for ultra-high speed. Compatibility with your equipment and cables is essential to avoid overloading with speeds that might lead to stretching any limitations either with your cabling or creating a bottleneck in more than one area.

There is a certain distance and cable quality standard that comes into play here as well — this affects how you can most effectively utilize the speed that is being offered by the RJ45 SFP module. For example, you can run a Cat5e cable for a gigabit link, but because of limitations on distance, you cannot consider using that Cat5e cable for 10 Gbps. Alternatively, if you wanted to run Cat6 or Cat6A to operate at 10 Gbps, you should also consider distance; they would be a better solution, but that’s going to be dependent on distance, as interference is an issue.

You should also be aware that not your cables but your vendor’s catalogs and any certifications you can rely on, such as an OEM Multi-Source Agreement certification or typical vendor catalogs, are key places to sift through available transceivers for use with switch hardware. Similarly to the earlier mentioned caveat of keeping your connections stable, having reliable transceivers — you’re essentially already halfway there with the vendors having already validated you have to use the transceivers listed for a given model of switch with the correct firmware — which would minimize the time you have to spend troubleshooting equipment.

Selection Requirements:

| Criterion | Specification/Consideration |

| Speed Standards | 1000BASE-T, 10GBASE-T support |

| Cable Compatibility | Cat5e (1G), Cat6/Cat6A (up to 10G) |

| Compliance | MSA-certified, vendor compatibility matrix |

Adhering to these criteria equips network engineers for seamless copper SFP integration.

The Auto-Negotiation Nightmare: When Legacy Equipment Refuses to Connect

The Auto-Negotiation Nightmare: When Legacy Equipment Refuses to Connect

Even with technology advances, auto-negotiation conflict continues to be a significant issue on virtual networks at times when older RJ45 SFPs and switches are deployed. Older switches, routers, and other equipment may not have the capability to complete link negotiation for copper transceivers that have potentially mismatched media-dependent interface (MDI)/MDI crossover (MDIX) port configurations. To summarize, MDI and MDIX specify the ability for reciprocity of signal transmission. Typically, modern-day switches may incorporate auto-MDI/MDI crossover capabilities, which eliminate crossover cabling or at least minimize configuration issues when interfacing with older devices. In many instances, older hardware will not auto-cross and will require manual crossover or be set to fixed ports designated as either MDI or MDIX.

An incompatibility can be experienced as a simple link failure or flapping, ultimately causing some degree of instability in the network. Combatting the auto-negotiation issue of legacy RJ45 connections will typically require some action from the command-line interface by disabling auto-negotiation, selecting a specific speed, selecting a duplex mode, or simply setting MDI/MDIX port behavior to achieve consistent and stable connectivity with older equipment.

Troubleshooting Table:

| Issue | Solution |

| Auto-negotiation failure | Disable auto-negotiation; set fixed speed/duplex |

| MDI/MDIX mismatch | Adjust port crossover settings |

| Firmware misalignment | Verify and update switch and SFP firmware |

Mastering these fixes reduces downtime in copper-fiber mixed environments.

What Are the Real-World Distance and Performance Limitations?

While RJ45 copper SFP modules indicate transmission distances of up to 100 meters on Cat6 twisted pair cabling, in actual practice, there are often a number of practical limitations that can reduce this distance. These limitations can include, but are not limited to, the condition of the cable itself, environmental conditions around or within the cable installation, and electromagnetic interference. As these issues arise, the physical integrity of the cable—such as fraying, compression, and poor termination points—can result in cable attenuation as well as packet loss. Just like fraying, compression, or physical degradation of the cable, nearby power generation equipment and heavy industrial electronics also generate EMI (electromagnetic interference). All of this interference can further jeopardize signal quality over those distances.

Temperature also plays a major role in the performance of copper conductors; resistance in a conductor is dependent on the conductor’s temperature. As those expected range limitations under such conditions continue to build and influence the copper and its link, they will reduce its achievable performance at distance, even under perfectly manufactured standards. Network administrators who are responsible for promoting stable links will often implement monitoring or assess error rates on a link in real time. Once the signal degrades the link, the network administrator can attempt repairs before considerable loss of service occurs.

Environmental Effects Table:

| Factor | Impact on Signal Quality |

| Cable Damage | Increases attenuation, errors |

| Electromagnetic Interference | Causes noise and packet loss |

| Temperature Variations | Alters resistance, affects stability |

Understanding these realities sets accurate expectations for copper SFP performance under varying conditions.

The Data Center Success Story: Connecting 200 Legacy Servers Without Fiber Ports

The Data Center Success Story: Connecting 200 Legacy Servers Without Fiber Ports

A large data center found itself in the midst of a modernization project for its network fabric while continuing to operate hundreds of legacy servers, but only outfitted with copper NICs. Upgrading the server NIC cards or even just rewiring much of their infrastructure for fiber optics would pose an unreasonable financial burden and could lead to service outages. The facility decided to implement RJ45 copper transceivers in their new fiber switches. This approach may have been decidedly old-school, but it was a cost-effective means of continuing to provide uninterrupted connectivity to the servers using the copper links they had transitioned to in the new tier of the network.

This was a staged migration, and the throughput and reliability remained unchanged while the old NICs were replaced by the new fiber switches when necessary, including for critical operational requirements. This was a reminder and an example of the value that can be derived from copper SFP modules for your data center modernization project.

Action Items:

- Implement copper SFPs to allow compatibility between the fiber switch and legacy servers.

- Mitigate the costs of upgrading NICs for over 200 servers by using the copper SFPs.

- Maintain consistent performance through the changing of infrastructure.

Troubleshooting Guide: Solving the Most Common RJ45 SFP Issues

Effective fault detection starts with a separation process that involves verifying the cable is not damaged first, and then ruling out faulty transceivers. It is worth considering the fact that many physical issues are the root cause of an unstable link; thus, visual inspection, along with cable testers, can often locate these physical failures very quickly and efficiently. Secondly, we can use the command-line interface (CLI) commands, such as “show interfaces” or “show errors”, to obtain more information about the port setup. CLI tools are generally a good method to troubleshoot, simply because they usually assist with isolating the port that has issues with flapping or mismatched speeds. The aforementioned tools are used to identify high levels of errors and add some degree of visibility to an otherwise “dynamic” status link.

Thirdly, we have a structured troubleshooting process, which generally follows the steps noted here:

- Clearing an erroneous port or module as a possible cause of the problem

- Setting speed and duplex parameters on port configurations, according to the device it is connected to

- Replacing modules or cables to localize the defective parts

- Harmonizing firmware versions to eliminate aspects of incompatibility

Stepwise Diagnosis Table:

| Step | Action | Purpose |

| 1 | Inspect/Certify Cable | Detect physical damage |

| 2 | Check CLI Status | Identify interface errors |

| 3 | Reset Ports / Configure Settings | Eliminate transient faults |

| 4 | Replace Hardware | Isolate defective components |

| 5 | Verify Firmware | Confirm compatibility |

This methodical process expedites effective repairs, minimizing network disruption.

Cost-Benefit Analysis: RJ45 SFP Modules Versus Complete Infrastructure Upgrades

Cost-Benefit Analysis: RJ45 SFP Modules Versus Complete Infrastructure Upgrades

When it comes to deploying copper RJ45 transceivers, there is typically a lower initial capital expense than a complete replacement of cabling in an office environment. This applies to the labor involved in installation, the material costs, and the disruption in operations to complete the work, saving money from start to finish. The long-term savings in comparison to a major rebuild of the network will be gained over a projected 5-year period. The indirect costs ultimately will offset the savings mentioned above. Copper-based networks experience downtime more often than fiber due to the effects of interference or age-related degradation of the cabling and equipment. In addition, troubleshooting the operational complexities of a copper-based network creates maintenance costs that can quickly erode any savings achieved on net operational expenses.

Copper solutions also face challenges with scalability. With the move toward bandwidth needs of 25G and higher, copper is no longer feasible; the entire network infrastructure will need to consist of fiber equipment. In delaying a complete infrastructure upgrade from copper to fiber, you are limiting the future growth, performance, and relationship between the network as a whole and segments of the network later. Investment considerations should take into account the short-term cost savings versus long-term flexibility.

Financial Summary Table:

| Aspect | Copper SFP Deployment | Full Infrastructure Upgrade |

| Initial Investment | Low | High |

| Maintenance Complexity | Moderate | Low |

| Scalability | Limited | Scalable |

Future-Proofing Your Network: When to Choose Alternatives to RJ45 SFPs

The 10G speed limitation of copper RJ45 transceivers means that 25G or 40G Ethernet is not going to be viable applications for copper RJ45. If your network needs these speeds, you will need to have alternatives. Media converters that convert a copper signal to a fiber optic signal give networks the ability to gain distance and additional bandwidth. Hybrid switches support copper and fiber ports, growing your network stepwise without completely changing out your copper. A strategic migration planning strategy will allow you to operate short term with copper SFP and have a long-term fiber buildout plan. Stepwise builds with fiber trunks will complement existing copper links, minimize stranded assets, and provide a clear path forward. Establishing performance verification checkpoints will provide clear stepwise communications to keep the plan on track.

Summary of recommendations:

- Stay within the inherent limits of copper; develop a speed utilization plan to exceed 10G.

- Use media converters and hybrid switches as transitional technologies.

- When implementing fiber, there are many options to invest in.

Work toward converting to fiber on a stepwise basis as you build your fiber investment while migrating away from copper. Work with your regional fiber contracts to give you cost and performance options.

Conclusion

Deciding on RJ45 transceivers that work best for you involves balancing the speed level needed and the quality of the cables being used. Successful deployments of RJ45 transceivers typically operate within the IEEE standards established for 1000BASE-T and 10GBASE-T, while still supporting cable types like Cat5e, Cat6, and Cat6A with high reliability of their performance. You should also think about power usage and heat impacts when deploying in a dense switch environment. Review compatibility based on vendor compatibility matrices as well as MSA compatibility to ensure smooth deployment. When considering the cost savings associated with copper transceivers, deploying fiber gradually gives you options for future upgrades—a strategy that enables you to design a future-ready network system with minimal risk of wasting money and investment.

The IT Manager’s $25K Infrastructure Dilemma: New Fiber Switches, Old Copper Cabling

The IT Manager’s $25K Infrastructure Dilemma: New Fiber Switches, Old Copper Cabling How to Select the Right RJ45 SFP Module for Your Network Requirements?

How to Select the Right RJ45 SFP Module for Your Network Requirements? The Auto-Negotiation Nightmare: When Legacy Equipment Refuses to Connect

The Auto-Negotiation Nightmare: When Legacy Equipment Refuses to Connect The Data Center Success Story: Connecting 200 Legacy Servers Without Fiber Ports

The Data Center Success Story: Connecting 200 Legacy Servers Without Fiber Ports Cost-Benefit Analysis: RJ45 SFP Modules Versus Complete Infrastructure Upgrades

Cost-Benefit Analysis: RJ45 SFP Modules Versus Complete Infrastructure Upgrades