Outdoor Ethernet Cable vs Indoor Ethernet Cable: How to Choose the Best Network Cable for Your Environment

Today’s Ethernet cables create the foundation for reliable and fast connectivity in our homes, offices, and outside. Regardless of the complexity of your network setup, it is enormously important to select the correct cable to guarantee you procure the optimal condition of performance and durability you can have in your cabling system. There are two main styles of Ethernet cables, so named for the environment for which they are being designed: indoor Ethernet cables and outdoor Ethernet cables.

Indoor Ethernet cables are designed for indoor rock-solid applications having predictable temperature and UV exposure. They typically have more pliable jackets and are designed to accommodate running through walls, ceilings, and conduits. Outdoor Ethernet cables are designed to endure harsh external conditions including UV, moisture or deposits, extremes of temperature, and physical wear. They often have rugged waterproof marine jackets with additional protective layers that ensure longevity in even the harshest conditions if installed outside or underground.

When you are selecting to install either an outdoor Ethernet cable or indoor Ethernet cable, it ultimately depends on where the cable will be installed and what environmental stresses it would encounter. Using the wrong Ethernet cable can lead to network outages, physical damage and distortions, or could even result in replacement cables or costly labor. By reading this resource, we will help you understand the differences between indoor Ethernet cables, outdoor Ethernet cables, and help you choose the right network cable for your setup.

Key Differences Between Indoor and Outdoor Ethernet Cables

Construction and Jacket Material

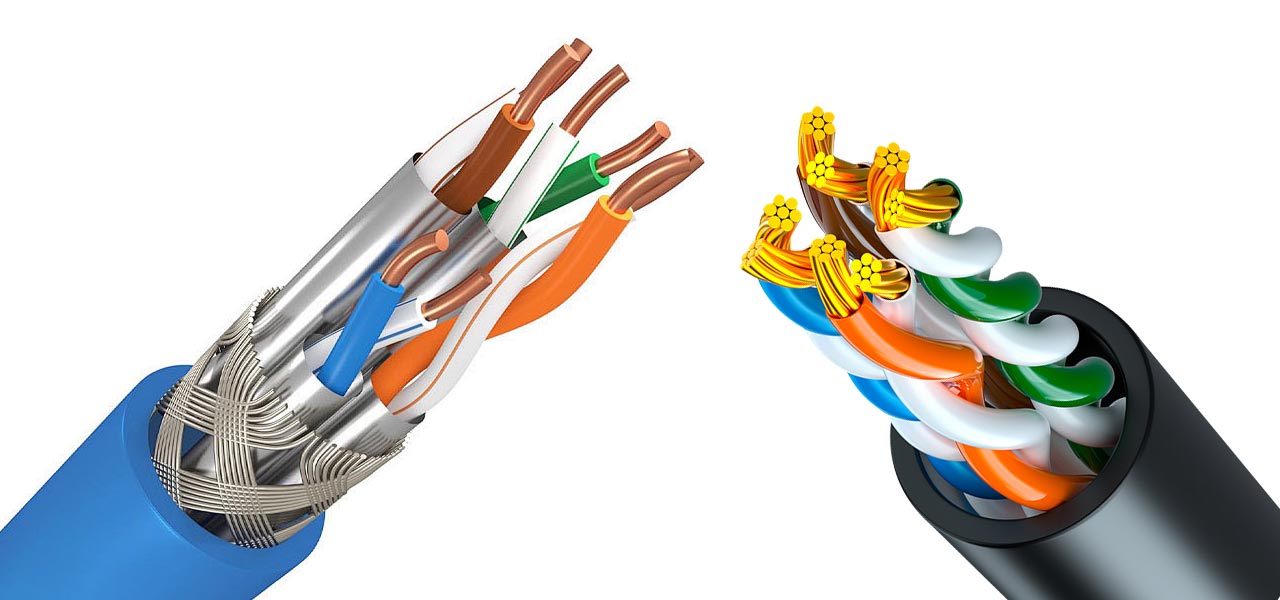

The main difference between outdoor and indoor Ethernet cables is their jacket material and construction. Outdoor Ethernet cables are designed with robust, protective jackets made from polyethylene (PE), PVC with UV inhibitors, or low-density polyethylene (LDPE) materials. These jackets are very effective at UV resistance and waterproofing, in addition to protecting against physical wear and tear, and can be exposed to the elements and sunlight for long periods of time.

Conversely, indoor Ethernet cables are usually designed with thinner, more flexible jackets made from PVC or a comparable material. Indoor cables’ jackets make installation easier, which is reliable and safe inside buildings where cables are not exposed to the elements. Indoor cables also do not have the jackets to withstand moisture and UV, which can quickly degrade their performance if installed outdoors.

Environmental Resistance

Cables meant for outdoor use need to face numerous challenges from the environment. Outdoor cables are made to resist extreme temperatures, normally between -40°C to 75°C, and are constructed to prevent moisture, snow, rain, and physical abrasion. Most outdoor cables will have other features, like water-blocking gel or flooded cores, to prevent water from getting in, for continued data transmission capabilities, even in wet or underground installations.

Indoor cables, on the other hand, are intended for use in controlled environments, such as offices, homes, and data centers. These cables do not tolerate exposure to sunlight or moisture and are not intended for use outdoors or for direct sunlight exposure or extreme temperatures. Indoor cables can crack and lose signal, and ruin completely, when they are exposed to these factors.

Installation Types and Use Cases

The installation environments of indoor cables and outdoor cables can be remarkably different. Outdoor Ethernet cables are generally manufactured for direct burial in the ground, aerial installations on poles, outdoor security cameras, or connection to a building. They are designed to withstand the weather and external hazards of nature.

Indoor Ethernet cables are for any wiring inside of a building. The wiring can be run through walls, ceilings, and conduits in offices, homes, schools, and data centers. Indoor cable design is focused on flexibility instead of ruggedness, and they have fire-safe ratings (CM, CMR, CMP).

Scenario 1: Outdoor Ethernet Cable for Harsh Environments

Choosing the correct outdoor Ethernet cable is important when running network cabling in harsh outdoor conditions to maximize performance, durability, and reliability. Outdoor cabling is designed for extreme elements like moisture, UV light, fluctuating temperatures, and physical stress that normal-rated cabling will not tolerate.

Direct Burial and Aerial Outdoor Cables

Outdoor Ethernet cables come in different types, which are tailored to specific installation methods. There are “direct burial” cables that are intended to be buried in the ground without any conduit, with thick, heavy jackets, developed to be filled with water-blocking gel to prevent moisture from getting in. Direct burial cables are recommended for outdoor runs where the cable would be in soil, in water, and/or potentially susceptible to physical damage.

Aerial cables are intended to be run above ground outdoor cables hanging from poles and/or buildings. Aerial cabling typically includes a second strength member type, steel reinforcement or aramid yarns, to handle the tensile and environmental stress, the same protection needed for direct burial cables. There has to be a robust jacket, made of PE or low-density PE, to protect from UV damage and physical wear and tear.

Gel-Filled Waterproof Options

To protect against moisture infiltration, many outdoor cables contain gel-filled cores or water-blocking tapes to seal the cable interior from the outside world. This feature helps prevent moisture from conducting down the cable length, a process which could otherwise short out the cable and break the signal. Waterproofing is a necessity for outdoor cables that are exposed to the elements, such as rain, snow, or moisture underground.

Temperature Tolerance and UV Protection

Outdoor Ethernet cables are designed to work and perform properly in a wide temperature range, in some cases from -40° Celsius to 75° C. This temperature tolerance means they will work through freezing winter cold all the way to very hot summer heat. Additionally, outdoor Ethernet cables are treated for UV protection so they will not degrade or become brittle when exposed to the sun for long periods—this is yet another feature not available in the indoor version of the same cable.

| Feature | Outdoor Ethernet Cable (PE/LDPE Jacket) | Indoor Ethernet Cable (PVC Jacket) |

| UV Resistance | Yes | No |

| Waterproofing | Yes (gel-filled options available) | No |

| Temperature Range | -40°C to 75°C | 0°C to 60°C |

| Direct Burial Rated | Yes | No |

| Jacket Thickness | Thick | Thin |

Scenario 2: Indoor Ethernet Cable for Controlled Environments

Indoor Ethernet cables are specifically developed to meet the criteria of controlled environments like data centers, office spaces, homes, and schools. Unlike outdoor cables, which require durability for weather and physical abuse, indoor cables are more flexible and focus on building codes for fire safety and ease of installation inside a building.

Common Applications of Indoor Ethernet Cables

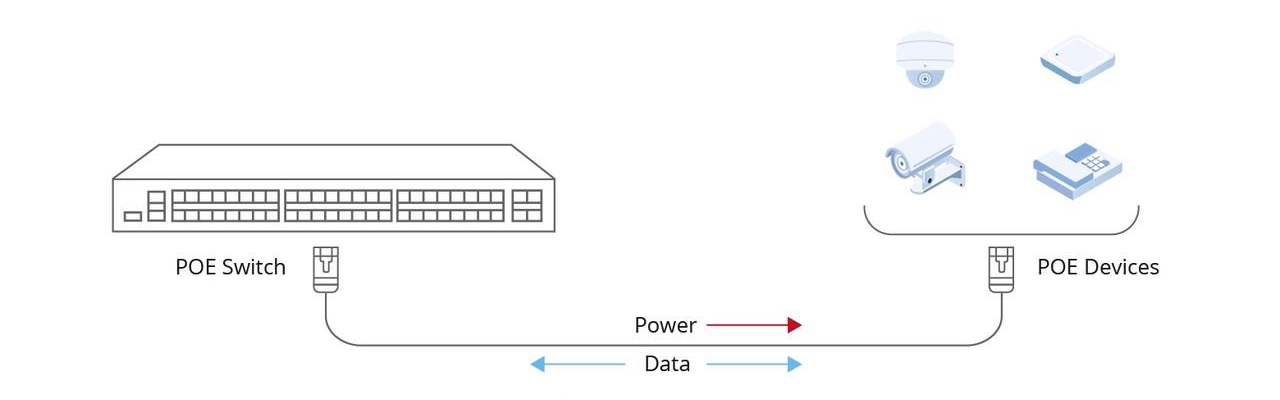

Indoor cables are used to connect devices to one another inside a structure, typically routed through racks and walls, ceilings, and conduit, or raceways. Typical uses of indoor cables include connecting computers, printers, routers, and switches to the local area network (LAN) in an office or home, providing connectivity in a classroom, and connecting administrative systems in a school. Data centers use indoor Ethernet cables as well, extensively using them for the connections of server racks and networking.

As an indoor application, the environment means that these cables do not require ruggedness or weather protection typically needed for outdoor use; however, they are subject to building code requirements for fire safety.

Fire Ratings and Flexibility

Indoor Ethernet cables include varying levels of fire rating including CM (Communications Multipurpose), CMR (Riser), and CMP (Plenum).

- CM-rated cables are intended for general, residential or office use, which meet basic flame resistance.

- CMR cables are intended for use where a vertical run through a riser shaft connecting to floors is needed, with better fire stopping capability to prevent the spread of flame.

- CMP cables have the highest fire rating, which is needed for plenum spaces, including air duct areas, which have a critical risk for spreading fire.

The types above describe the levels of fire safety under the building code requirements for indoor Ethernet cables; the cable is far less likely to spark and cause a fire.

Indoor Ethernet cables are highly flexible cables, with thinner PVC jackets, making it easier to route a cable through tight spaces, or when a cable must be routed around corners. This is a critical difference from outdoor Ethernet cables because outdoor cables include thicker jackets, which are also more rigid, to provide protection for outdoor areas.

| Feature | Indoor Ethernet Cable (PVC Jacket) | Outdoor Ethernet Cable (PE Jacket) |

| Fire Rating | CM, CMR, CMP | Usually none or minimal |

| Flexibility | High | Moderate |

| Installation Area | Indoor duct, walls, ceilings | Outdoor, underground, aerial |

| UV Resistance | No | Yes |

Scenario 3: Hybrid Installations and Compatibility

In many real-world network deployments, indoor and outdoor Ethernet cabling must work in conjunction with each other; the point where the network transitions between an outdoor environment and an indoor environment is the entry point to the building. Regardless of the location of the Ethernet equipment, it is critical to understand how to address these hybrid installations so that the integrity of the network can be maintained, signal loss avoided, and the cables can be protected from the environment.

Indoor / Outdoor Cable Entry Points

A common question occurs when running an outdoor-rated Ethernet cable from a building exterior (a pole or buried conduit) through an entry point. The premise is that an outdoor-rated Ethernet cable is rugged and waterproof; however, an indoor-rated cable is flexible, fire-rated, but not waterproof. This transition or entry point requires special attention, as this point could allow moisture intrusion, physical damage, or even signal degradation if not properly cared for.

Hybrid Installation Transition Options

There are a number of options and a combination of options for ensuring an outdoor-rated cable transitions to an indoor-rated cable reliably:

- Weatherproof connector:A weatherproof connector is an appropriate connector specifically meant to seal the end of an Ethernet cable from moisture and dust intrusion, prevent corrosion, and maintain proper signal quality at the outdoor/indoor transition.

- Conduit or cable trays:Using physical protection such as conduit or trays to protect against mechanical damage, rodents, or careless cuts to the Ethernet cable where it is exposed to the elements or has the potential to be tread on, makes for a solid transition handling method.

- Media converters or media conditioning patch cables:When the cable types or mode of the transmission are different, e.g., outdoor-rated media to indoor-rated media, media converters translate the signals between the outdoor-rated cables and the indoor-rated cables and resolve any signal loss issues.

| Installation Aspect | Solution | Notes |

| Outdoor to Indoor Transition | Use weatherproof connectors | Protects against moisture |

| Cable Type Compatibility | Media converters or mode conditioning patch cables | Avoids signal loss |

| Physical Protection | Conduit or cable trays | Prevents physical damage |

| Cable Jacket Differences | Match jacket types where possible | Ensures longevity |

Installation Best Practices

Proper installation and construction practices are crucial to ensuring optimal performance and longevity for both outdoor and indoor Ethernet cables. Following best practices will protect your network from environmental factors, keeping it reliable in its performance.

Protect Outdoor Cables

When outdoor Ethernet cables are not protected from physical damage and environmental risks, they can be easily compromised. One common and effective way to protect these cables from damage caused by rodents, abrasion exposure, or accidental cuts is by placing the cables in black or gray electrical conduit (plastic tubing). For burial underground, direct burial gel-filled cables will provide even more moisture resistance by keeping water out along the length of the cable. Gel-filled outdoor cables are ideal for really harsh environments if water exposure will be an issue.

Use Weatherproof Connectors and Sealants

The termination ends of outdoor cables will be the weakest point for moisture or dust to enter and/or exposure to the elements. Therefore, once the cables are installed, weatherproof connectors and/or sealants will provide a tight barrier at the end of the cables as well as junction points of cables. This will help protect the cables from moisture, corrosion, or a reduction in the quality/reliability of the signal, especially if the cable is installed outdoors as an exposed connection, or directly where the cable penetrates through the wall into the interior of the building.

Avoid Exposure of Indoor Cables to Sunlight or Moisture

Indoor Ethernet cables are made for controlled environments and should be protected from UV exposure; therefore, weather sealing will not be included with the indoor cable. Indoor Ethernet cables should not be run outside or be exposed to direct sunlight, moisture, or other related environmental exposures. Indoor cables that experience sun exposure will experience cable jacket deterioration due to cracking failure and degrade the cable until it ultimately fails. If there is an outdoor run, it is recommended to always use an outdoor-rated cable if the run is outside of the building.

Frequently Asked Questions

Can you use indoor cable outside?

No, indoor Ethernet cables are not intended for outdoor environments. Indoor Ethernet cables don’t have UV protection and they don’t have a waterproof jacket, which is why they are subject to cracking, deterioration, and ultimately failure under sun, moisture, or extreme temperature conditions. Using specifically rated outdoor cables is highly recommended for any outdoor installations.

Is outdoor rated Ethernet cable waterproof?

Most outdoor rated Ethernet cables are water-resistant or waterproof. Most are made of gel-filled cores and waterproof jackets, and they are made with UV resistant jackets. For submerged applications, you will need specially rated submersible cables for underwater use.

How do you tell if Ethernet cable is outdoor rated?

Look for the markings “UV-resistant”, “direct burial”, “CMX rated”, or “weatherproof” on the cable jacket. These cables have thicker PE or LDPE jackets compared to indoor rated cables that have a PVC jacket.

What is the best Ethernet cable for underground installation?

The best cable to use for underground runs is a direct burial rated Ethernet cable that has gel-filled cores and UV-resistant PE jackets which will allow for moisture and physical damage resistance.

Final Thoughts

Picking the right Ethernet cable is key to being durable, performing well, and being safe in your network. Outdoor Ethernet cables are built from the ground up for unforgiving conditions, with UV compatibility; waterproofing; rugged construction; wide-temperature, and moisture resistance while indoor Ethernet cables are for inside protected and controlled environments (offices and data centers), with a focus on flexibility and fire safety.

However, selecting a cable should be based on the environment where you’ll be installing the cable. Understanding the differences in cables and the scenarios in which they are to be used gives you a foundation to build out a secure, reliable, and long-life network infrastructure that’s right for you.