Optical Module Cleaning Techniques and Tool Recommendations: Maintaining Performance, Avoiding False Alarms and Failures

Dirty optical module can cause erroneous error reports, resulting in the unnecessary replacement of a module costing upwards of $150-$800. Even microscopic particles, in the range of 0.5-9 microns in size, can cause optical power degradation of 0.5-3dB, which results in loss of network uptime at an average of $5,400/hour for the enterprise network and $50,000/hour for critical infrastructure.

Cleaning SFPs to professional standards can prevent an estimated 80% of contamination-related failures. Quality optical fiber cleaning tools can be obtained for $50-$200, providing 15:1 firm returns over the costs associated with responding to troubleshooting.

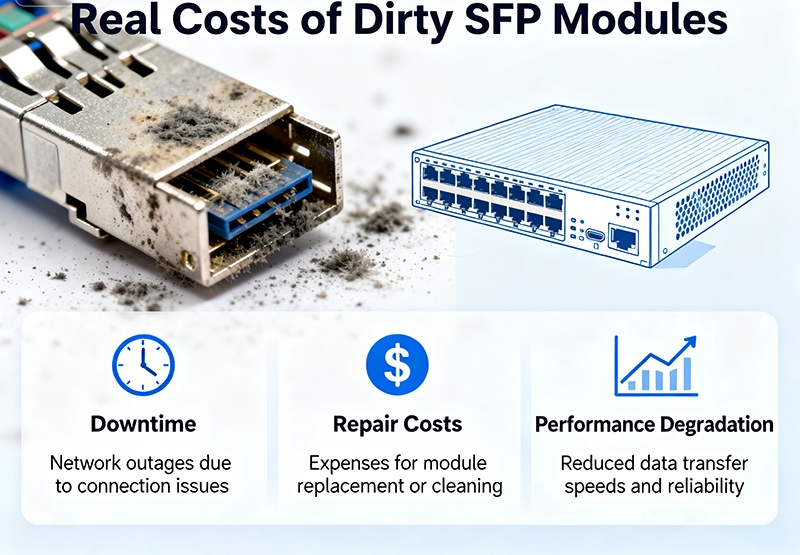

What Are the Real Costs When SFP Modules Stay Dirty?

The financial losses associated with signal degradation from microscopic particles can be tracked across all network operations. As an example, a single SFP module, compromised by contamination, will cause the optical power transmission for that circuit to decrease by approximately 0.5-3dB. This automatically activates error correction protocols that further utilize remaining bandwidth. A dirty fiber connection can similarly be viewed by analogy with a smudged window — you realize the picture is getting increasingly blurry but only understand you can’t see at all when communication fails altogether.

Intermittent outages are the most costly to operate — because they are sending false positives to monitoring and alerting systems. When packet loss occurs only intermittently, a network monitoring system will register the loss and alarm you, but identify a healthy SFP. Network operations will then spend 4-8 hours investigating and chasing the intermittent issue because the activity is real, and therefore contaminations are silently costing time and resources.

The mathematics of determining costs to budgets supports that costs will be significant if you identify or calculate a cost difference between the proactive and reactive budget expense. Unwarranted SFP module replacements average $150-$800 in cost because contamination caused the false failure. Each emergency troubleshooting cycle typically consumes 12-16 hours of technician time billed at $75-$120 per hour, yielding an average of $900-$1,920 per incident. To reduce costs and improve reliability, consider the recommendations in our optical module procurement guide for selecting compatible and quality modules.

Localized outage expense related to contamination or contamination-related outages escalate rapidly. For an actual organization, network downtime costs amount to $5,400 per hour for enterprise networks, while the average cost for critical infrastructure systems exceeds $50,000 per hour. A specialized optical fiber cleaner tool purchased for anywhere from $50-$200 will prevent multiple failures triggering unnecessary replacements and spending.

Proactive cleaning programs for SFP provide a potential maximum return on investment of 15:1 compared to the costs of remedial maintenance. Monthly cleaning program cycles, based on best practices, utilizing quality optical equipment to remove contamination, will eliminate about 80% of its causes. The math is straightforward, if not clear: an average investment of $300 or $25 a month will save $4,500 or more in unnecessary replacements and troubleshooting.

Data from companies show that organizations implementing systematic cleaning procedures resulted in a coordinated maintenance budget reduction of 60-75% from prior budget items. The cost of contamination is more than the hardware items, including overtime, emergency vendor calls due to outages, and reputational damages to customer service companies that provide grossly deficient service during outages.

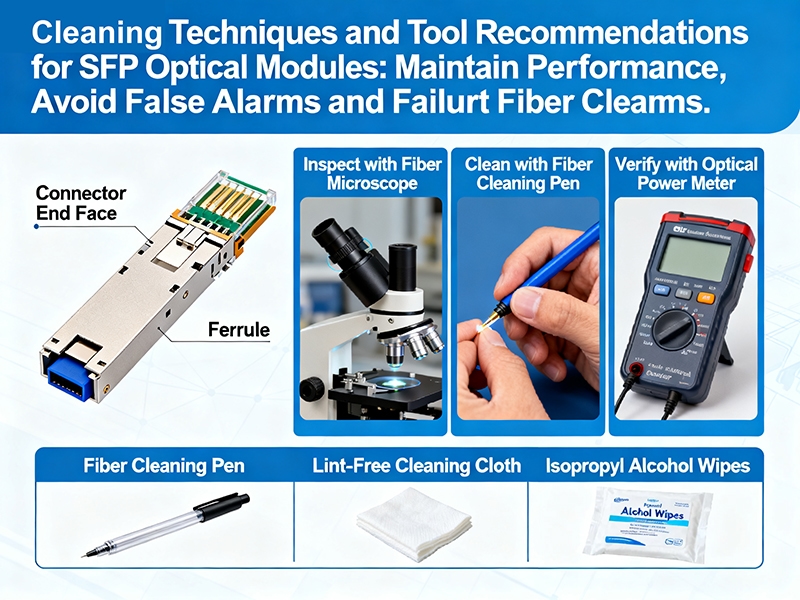

Cleaning Techniques and Tool Recommendations for SFP Modules

How to Diagnose When Your SFP Modules Need Immediate Cleaning

Link flapping patterns act as a warning detection signal for contaminated optical interfaces. Connections that establish for a brief duration and then repeatedly disconnect indicate that particles are obstructing light transmission. Subsequently, network switches register these events as occasions with rapid up/down state changes every 10-30 seconds, rather than stable (up) connectivity.

Error rate spikes provide measurable evidence of optical performance degradation. Monitoring interface statistics for increases in Forward Error Correction (FEC) above the baseline rate is one measurement approach. Clean modules will have error rates generally below 10^-12, while contaminated interfaces will rate FEC correction in the presence of contamination during the inspection of fiber optic cleaning at the -9 or higher rate.

Fluctuations in optical power are a diagnostic measurement that provides the severity of contamination. Using the CLI commands “show interfaces transceiver” is one way to command readable receive and transmit power. Healthy modules will also operate in repeatable terms around the -3dBm to -10dBm scope range, while contaminated modules will show erratic power when tested, with the measurement parameters fluctuating in ranges exceeding 2dB or more.

The use of fiber scope inspection techniques to assess contamination directly visually is a manner of addressing contamination. Professional optical fiber cleaner detection will require observation at 400x magnification and will visually identify particles smaller than the width of a human hair diameter. Look for signs of scratches that may or may not be recordable, as well as oil residue and unnamed debris particles that may be present as apparent dark spots against the ferrule end-face.

CLI diagnostic commands provide an accepted means of SFP cleaning diagnosis in the way CMD CLI commands provide a convergence of SFP diagnostics across switch platforms. For example, you can execute a “show optical-monitor,” as well as “show dom” commands to provide metric data of performance evaluations in real-time. Contamination in contextual use denotes a level of strain in signal processing at temperature readings above the normal operating range. Please refer to the comprehensive guide on how to test fiber optic modules to deepen your understanding of diagnostic tools and test procedures.

In specific conditions, environmental accelerators compound contamination that converge at a quicker pace. In a data center environment where there is inadequate air filtration, dust will build at 3x faster on exposed links. In a high-humidity environment (over 70%), condensation will attract airborne particles to the optical surface.

Static electricity buildup occurs very frequently in low humidity (below 40% RH) environments. Not related to fiber optics, static energy from plastic cable jackets generates static buildup that pulls micro debris toward the fiber connection. Static ground levels will surge higher at residual levels below 30% RH, as you factor in the residual buildup of a static charge at 400% higher with lower humidity. Contamination buildup will require ground protocols to manage material migration deposits during maintenance.

What Tools Actually Deliver Results for Different SFP Cleaning Scenarios?

Cleaners that work with a single click provide excellent regular maintenance on basic LC and SC connector types and have effectiveness ratings of 95%. These automated SFP clean tools require minimal employee training due to the process being automated and clean reliable results in most cases of light contamination. However, these tools do not work very well with oil-based residues and will not perform well for high-density MPO connectors with limited cleaning surface contact.

Cleaning cassettes provide a superior option for cleaning MPO and high-port count situations due to replaceable cleaning surfaces. Professional optical fiber cleaner comparison studies determined that cassette systems achieve rates of 98% and clean away contamination for all types of connectors. Because of their design, the cleaning cassettes allow you to configure specific cleaning options for your environment or maintain sterile cleaning conditions.

The performance of cleaning pens varies significantly between dry and wet formulations used under different levels of contamination. Dry cleaning pens work well for dust particles but transfer oil contamination instead of removing it. Wet cleaning pens contain isopropanol, which also works better on baked-on and stubborn residues. Be sure to ventilate the area when using wet cleaners.

Cleaning tips that use gel perform exceptionally well regarding serious contamination issues that are difficult to clean to a usable state with standard cleaning procedures. The specialized fiber optic cleaning equipment options use micro-abrasives and safely and effectively scrape baked-on residues without damaging delicate ferrule surfaces. Laboratory testing proves contamination removal rates are at 99.5% performance effectiveness.

Cost per cleaning has shown significant differences among four categories of professional cleaning products:

- One-click cleaners – $0.50 – $1.20 per cleaning cycle.

- Cleaning cassettes – $0.30 – $0.80 per cleaning with a replaceable cartridge.

- Cleaning pens – $0.15 to $0.40 per application.

- Gel-based cleaning tips – $2.00 – $4.50 per cleaning session.

Tool durability factors can also affect long-term operating costs based on the varying environments in which the tools will be used. Typically, one-click cleaners operate about 500 – 750 cleaning cycles before needing to be replaced. A quality cleaning pen will last for 1,000 applications. Cassettes provide the longest life and cleaning cartridges, up to 2,000 cleaning applications.

Performance ratings show measurable effectiveness improvements among the four tool categories. One-click cleaners have a demonstrated effectiveness of 95% particle removal for LC connectors but drop to 78% effectiveness on MPO interfaces. Gel-based cleaning tips maintain a high level of effectiveness at or above the 99% threshold for all types of connectors, including the difficult 72-fiber MPO connectors using 0.35mm pitch spacing.

How to determine when an SFP module requires immediate cleaning

The Network Engineer’s Story: Why Standard Cleaning Methods Keep Failing

Marcus learned the hard way that dry-only cleaning creates more problems than it solves in a critical data center maintenance window. His team elected to use compressed air and dry wipes on contaminated SFP modules. They assumed they were removing particles from the SFPs, while they were actually inducing the opposite reaction. They could only look on helplessly as static electricity from the dry cleaning materials attracted even more dust particles toward the freshly “cleaned” connectors.

The cleaning errors became even worse when airborne particles drifted from adjacent SFP modules onto the original SFP modules when Marcus’ team blew pressurized air across the modules. What was intended to clean six modules ended up contaminating a total of twelve modules. Marcus discovered that dry cleaning is analogous to shuffling socks on a carpet – the static charges it generates pull debris toward optical surfaces, not away from them.

Sarah’s alcohol-only method seemed to work effectively until the network performance degraded three weeks later, right in the middle of the next maintenance cycle. Sarah accurately described exactly what she did. She applied 99% isopropanol to the face of the fiber without follow-up procedures and thought it was good to go, believing that all she had to do was wait for the alcohol to evaporate – leaving pristine optical surfaces. The reality is that alcohol actually dilutes contaminants without removing them, creating a thin film of residue that acts like flypaper.

The residue trap effect became clear when Sarah’s SFP modules had worse error rates after the cleaning than directly before the cleaning. Alcohol-based optical fiber cleaner errors occur due to the simple fact that contaminants, including oil and particle debris, are dissolved rather than removed across the ferrule surface. Each time cleaning occurs, the invisible contamination layer continuously gets thicker until optical performance reaches the point of total failure.

James’ field experience with the incorrect cleaning materials resulted in permanent optical damage, which cost thousands of dollars to replace all the SFP modules. James’ team used a standard eyeglass cleaning cloth, which was soft and gentle, and it had micro-abrasives designed for glass, not delicate optical ceramics. The material created a delicate microscopic scratch pattern on the optical components that diverged the light signal and permanently ruined any signal integrity across the optics.

James’ example of inspections using microscopy shows how types of cleaning materials can do devastating damage to the integrity and performance of optical surfaces. Physical damage caused by abrasive materials is different than temporary contamination. The optical cleaning won’t restore performance when the damage is done; it goes downhill rapidly. James’ SFP clean failures became a learning lesson for his entire organization that optical fiber surface cleaning requires specialized materials designed specifically for telecommunications applications. For troubleshooting and repair strategies to avoid permanent damage after cleaning mistakes, see the detailed guide on troubleshooting optical transceiver failures in SFP modules.

All of these examples share the common lesson that even if the intentions are good, if the manner is incorrect, disaster will assuredly be expensive in an optical network environment.

How to Execute the Proven Wet-to-Dry Cleaning Method Step-by-Step

The professional wet-to-dry cleaning method starts with isopropanol to dissolve contamination before physical cleaning. Apply 99% isopropanol to a clean and dry lint-free cleaning tip with enough that it begins to saturate the tip but does not drip. The wet phase will not only dissolve oil-based residues, it will also neutralize the static charge that attracts particles to the surface during the cleaning process.

The first contact requires uniform circular patterns across the ferrule end-face, using about 2-3 pounds of pressure. Imagine polishing a watch face; if you apply too much pressure, you will scratch the surface; too little pressure and you will leave contamination remaining. Continue to make 3-4 turns clockwise (clockwise will help move the solvent evenly across the optical interface).

The timing between the wet phase and the dry phase is important to a successful cleaning technique using an SFP. Wait 10-15 seconds to let the solvent dissipate; it is important that the solvent has had time to dissolve, so that we do not just push the contamination around the surface of the ferrule, but rather make it mobile in the next cleaning phase.

Insert the cleaning tool at the proper insertion angles to help protect the cleaning surface of the ferrule from damage during execution of the fiber optic cleaning method. The cleaning tip should always be perpendicular to the optical surface; do not use lateral scraping motions, as these can create microscopic scratches. The best way to insert the cleaning tool is straight down with a 90-degree alignment to avoid any edge damage by the cleaning tool.

The dry phase process removes the dissolved contamination utilizing fresh lint-free material, and with a consistent pressure technique. The rotation of the dry phase is the opposite of previous steps (counterclockwise) so as not to redeposit any loosened contamination. Continue the dry phase of cleaning until there is no visible transfer of contamination to the tip from the optical surface.

Pressure consistency is important. Consistently practicing a 2-3 pound cleaning force should be used during each step in the optical fiber cleaning method. Any increased pressure above 5 pounds may crack the ceramic ferrule, and too little pressure below 1 pound will not remove contamination. Test pressure values should be practiced on non-crucial surfaces before cleaning a critical module.

After the cleaning process has been completed, clean the optical surface. If it looks clean with the naked eye, it may still have contamination you cannot see. Therefore, you should have sufficient and consistent magnification (400x) to verify or confirm cleaning. Place the inspection microscope over the ferrule end-face (perpendicular) and carefully display the whole optical surface and inspect for remaining contamination, scratches, or residue films (look for discoloration/dark spots, irregular or abnormal reflections on the surface).

While documenting the optical power measurement procedure, document the optical power levels of both receive and transmit levels before cleaning and after cleaning. Metrology with the cleaned optical surface will verify that it performed to specifications. After a thorough cleaning, the optical surface will show stable power readings within the specifications of the manufacturer’s standard power readings +/- 0.5dB, verifying desired contamination removal and establishment of the proper optical interface.

What Are the Real Costs When SFP Modules Stay Dirty

Why Preventive Cleaning Schedules Actually Reduce Network Failures

Evaluating environmental conditions ensures appropriate preventive SFP cleaning frequency within various operating environments. Clean rooms typically require quarterly cleaning, while industrial installations with airborne particulate will usually require optical fiber cleaner checks monthly. Data centers typically maintain appropriate bi-annual cleaning schedules as long as they have appropriate air filters in place. Users of GPON modules should review the ultimate guide to GPON SFP maintenance for specialized cleaning and care instructions.

The criticality of the network indicates priority rankings for maintenance schedules in a general cleaning frequency matrix of documents and cleaning schedules. Generally, standard mission-critical backbone links are inspected weekly, followed by access layer modules inspected monthly. Specific financial trading networks will also inspect backbones daily when the market is open to prevent performance disruption.

Documentation protocols capture and track module health history through a structured record-keeping process to identify contamination trends over time. Maintenance logs are created during cleaning of the modules, capturing optical power readings, error rates, and environmental conditions for each cleaning cycle. Reviewing and analyzing historical data over time has shown factors in each specific location that contribute to higher contamination rates.

Measurement of cleaning effectiveness will employ baseline performance measures established prior to the introduction of preventive maintenance. Compare optical power measured prior to cleaning and optical power measured at the conclusion of cleaning to confirm effective removal of contaminants. If the performance of the optical power in a module continues to improve over all cleaning cycles, one can assume the cleaning frequency and technique are effective.

Environmental control minimizes possible sources of contamination through different strategic modifications to infrastructure in spaces dedicated to network equipment. Installation of positive air pressure will keep environmental air particles from entering the space, and use of HEPA filters will remove 99.97% of airborne particles that may contain hazardous contamination. Adequate cable management systems will eliminate the buildup of static electricity that continues to attract particulates, specifically to exposed fiber connectors used for routine operation.

How to Avoid the Most Expensive SFP Cleaning Mistakes

Preventing cross-contamination requires clean and contaminated components to be segregated while using the modules for maintenance. Implementing separate work areas based on color-coded containers can help reduce unintentional mixing of processed and unprocessed inventory. Consider it similar to surgical sterile procedures: if contamination invades the clean zone, you will need to process everything included in that area.

Preventing thermal shock protects sensitive optical components through the use of temperature stabilization protocols prior to cleaning operations. If the modules are stored in cold environments, they will need to acclimate at a minimum room temperature, but ideally for 30 minutes of acclimation time to the room temperature before handling. Sudden temperature changes from cold to room temperature will crack ceramic ferrules and damage the internal laser diodes, resulting in permanent failures that cleaning cannot recover.

Establishing a storage protocol will help maintain contamination-free conditions. Proper protocols for environmental conditions and proper optical fiber cleaner storage procedures should be established. Sealed containers that contain desiccant packs can help prevent moisture absorption and particle buildup on cleaned modules. Anti-static packing materials can prevent the buildup of static electricity that can attract airborne contaminants to the freshly cleaned optical surfaces.

Handling procedures can help minimize the risk of recontamination, implementing a systematic set of SFP cleaning best practices when transporting and installing due to handling and transport phases. Technicians should wear powder-free gloves and use a grounding strap to prevent a transfer of static due to the handling of equipment. Only remove clear protective caps immediately prior to installation to minimize the time the connectors are exposed to environmental contaminants.

Verifying quality control through regular audit procedures will confirm that contamination prevention measures are being adhered to. Randomly sample modules from storage inventory that were cleaned and inspect those samples microscopically for the presence of any contamination resulting from storage. Contamination verification tests that result in failure indicate a compromised inventory in storage, needing corrective action before widespread contamination of the entire storage inventory occurs.

Conclusion

Utilizing a systematic selection of tools, wet-to-dry cleaning practices, and preventive maintenance schedules provides the backbone to implementing professional procedures for contaminant management. Quality equipment that complements the connector type creates consistent results while protecting delicate optical surfaces.

Implementing these planned methods eliminates future degradation from contaminated modules and also the subsequent cost of troubleshooting for emergency procedures. Using professional cleaning methods successfully extends the service life of the equipment while providing reliable service operation of the network through proper cleaning of the optical interfaces.