MTP vs MPO Connectors: Understanding the Differences and How to Use Them

MPO (Multi-Fiber Push On) and MTP (Mechanical Transfer Push-On) connectors are essential components in fiber optic networks, permitting high-density, high-speed data transmission. Although these connectors are often referred to as the same thing, they differ in design, performance, and appropriate usage.

This lengthy article will dive into the differences between MTP and MPO connectors, their mechanical and optical properties, fiber counts, polarity, application, installation best practices, as well as address FAQs regarding both connectors; and give network professionals information needed to make decisions on selecting and deploying the proper connector for their respective networks.

What are MTP and MPO Connectors

MPO (Multi-Fiber Push On) connectors are design-standardized multi-fiber connections for the common termination of multiple fibers (most often, 12 or 24) in a single ferrule. Their usage in data centers and telecommunications is prevalent due to their efficient high-density cabling ability while saving space.

MTP (Mechanical Transfer Push-on) connectors are improved MPO connectors by a company called US Conec. MTP connectors have benefits with mechanical improvements, such as floating ferrules, metal pin clamps, and removable housings that improve durability and alignment, and facilitate maintenance of the connector.

MPO and MTP connectors both rely on optical fiber termination types, mainly to create fast and reliable connectivity for multiple fibers within a modern network. This article will provide clarity on differences, when to use them, and provide technical insights to help you make the right decision.

Mechanical and Optical Differences Between MPO and MTP

Despite having a virtually identical look, MPO and MTP connectors have different designs and performances:

- Ferrule Design:MPO-style connectors feature a fixed ferrule, while an MTP connector uses a floating ferrule. The floating design allows for optimal physical contact with the fibers, even when under mechanical stress. This design feature reduces insertion loss.

- Pin Clamps:MPO connectors employ a plastic pin clamp that is susceptible to breakage, while MTP fiber optic connectors use metal pin clamps. Metal-based pin clamps are more durable and reliable than plastic.

- Guide Pins:MPO connectors contain chamfered guide pins, while MTP connectors feature elliptically shaped, stainless-steel guide pins. The elliptical shape affords better alignment than the chamfered pins and reduces wear of the optic fiber and ferrule.

- Connector Housing:An MTP fiber optic connector features a removable housing, allowing for field rework and changes in gender. MPO connector housing is typically a fixed housing.

- Insertion Loss and Durability:MTP-style connectors typically exhibit lower insertion loss, which helps maintain overall signal performance, and have more durability to support more mating cycles than the MPO connector.

| Feature | MPO Connector | MTP Connector |

| Ferrule | Fixed | Floating |

| Pin Clamp | Plastic | Metal |

| Guide Pins | Chamfered | Elliptical Stainless Steel |

| Housing | Fixed | Removable |

| Insertion Loss | Moderate | Lower |

| Durability | Moderate | High |

With these upgrades in mechanics and optics, MTP connectors enjoy higher performance reliability in high-density performance applications.

Fiber Counts, Polarity Types and Connector Types

Fiber Counts, Polarity Types and Connector Types

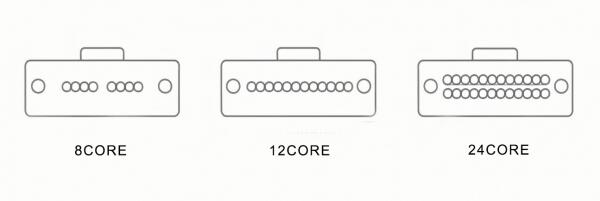

Both MPO and MTP connectors are available in several different fiber counts to generally support various needs, bandwidth and density:

- 8-fiber — newer for high-speed applications, such as sub-400G Ethernet.

- 12-fiber (MPO12) — most common with 40G/100G Ethernet.

- 24-fiber or higher — used in carrier and data center applications.

- 32+ fiber — used typically for ultra-high-density (UHD) arrays.

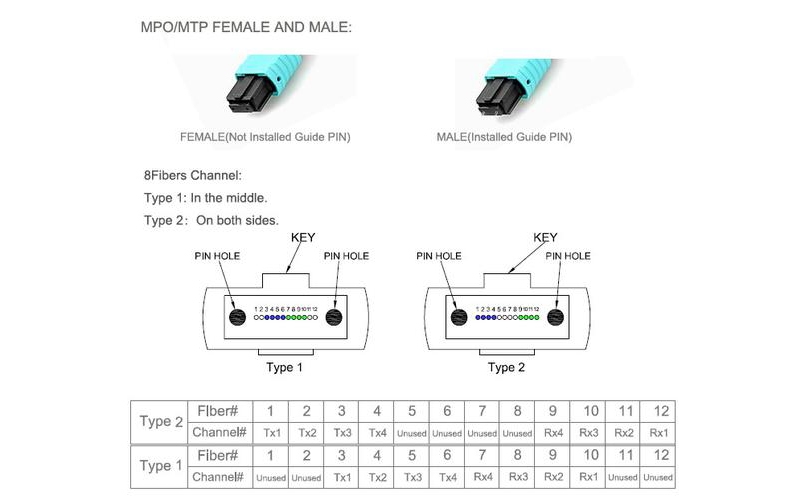

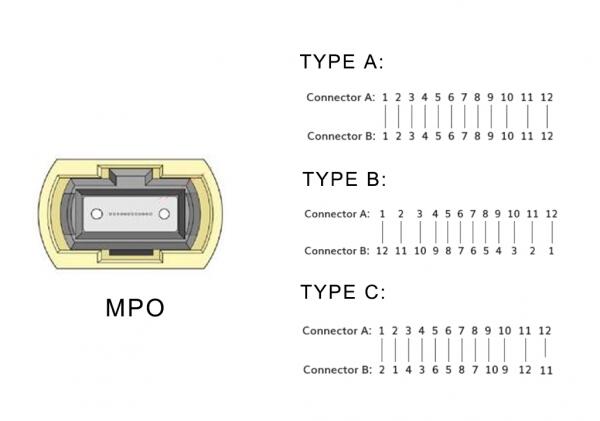

Correct polarity is key to ensuring transmit (TX) and receive (RX) fiber alignment:

- Type A (Straight-Through) – fibers are the same order throughout.

- Type B (Crossed) – fibers are crossed inside the connector.

- Type C (Pairwise Flip) – fibers are flipped in pairs inside the connector.

| Fiber Count | Typical Use Case | Connector Type |

| 8 | Emerging high-speed optics | MPO/MTP |

| 12 | 40G/100G Ethernet | MPO/MTP |

| 24 | Telecom and data centers | MPO/MTP |

| 32+ | Super high-density arrays | MPO/MTP |

Choosing the appropriate fiber quantity and type of polarity will help to ensure the integrity and performance of the network.

Use Cases and Application Scenarios

- Data Centers: MTP connectors allow a higher density of cabling, such as in support of parallel optics standards like 40GBASE-SR4 and 100GBASE-SR4, which minimize cable bulk and improve airflow.

- Telecom/Enterprise Backbones: MPO and MTP connectors will be used for a setup depending on the performance and durability requirements.

- MPO Breakout Cables: MPO/MTP connectors on one end, then splitting off to LC/SC duplex connectors on the other can split a high-bandwidth link to multiple lower-speed ports.

- Emerging Trends: As 400G and 800G rates with Ethernet gain traction and wideband Wavelength-Division Multiplexing (WDM) using OM5 fiber coincides, the use of MTP connectors will be important for future-proofing networks to support density and capacity.

| Scenario | Recommended Connector |

| Small office network | MPO |

| High-density data center | MTP |

| Telecom backbone | MPO or MTP |

| 100G/400G backbone | MTP |

| Future-proof wideband WDM | MTP with OM5 fiber |

Properly choosing your environmental connector can deliver the best performance and scalability.

Installation, Maintenance and Best Practices

Proper installation and maintenance promote performance of MPO/MTP connectors:

- Cleaning: Regular cleaning with appropriate fiber optic tools will help prevent contamination and signal loss.

- Testing: Utilize MPO testers to test fiber continuity, insertion loss, and polarity.

- Removable Housings: MTP connectors allow for unhoused optics for field rework, repolishing, and gender change.

- Durability: MTP connectors use metal pin clamps to allow for greater durability and reliability for connector longevity.

Following these guidelines will produce the most stable network setup and minimize downtime.

FAQ

What is the difference between MPO and MTP connectors?

MPO connectors are multi-fiber connectors, standardized. MTP are MPO connectors with greater mechanical and optical features.

Are MPO and MTP connectors compatible?

Yes, MPO and MTP connectors are fully compatible and interchangeable.

What fiber counts are available?

The common fiber counts associated with MTP/MPO connectors are 8, 12, 24, 32 and 48.

How do you maintain MPO/MTP connectors?

Regular cleaning and testing for fiber using MPO testers is important.

What is connector polarity?

Connector polarity promotes proper alignment of transmit and receive fibers associated with the fiber optic connector.

When do I choose MTP over MPO?

Choose to use MTP connectors when needing a high-density, high-performance network with a need for durability and low loss.

Closing

The MTP connectors with their enhanced mechanical and optical features offer superior overall performance and durability compared to standard MPO connectors. These connectors are better utilized in environments requiring high speeds, high density and durability.

Each connector is different in structure and performance; now that you understand the difference between MPO and MTP connectors, you will be able to build or ensure the proper performance, bandwidth, speed, and reduce failures of your network.

Research thoroughly connector charts and consultancies which may assist with proper connectivity using MPO/MTP connectors and ensure proper network performance.

Fiber Counts, Polarity Types and Connector Types

Fiber Counts, Polarity Types and Connector Types