Legacy E10GSFPSR Optical Module Guide: Upgrade and Replacement Solutions for Older Equipment

Networks that depend on aging infrastructure often run into present and future challenges when the discontinued E10GSFPSR optical modules malfunction or simply become unavailable. Even when organizations do have legacy SFP modules, the connections often still don’t work due to very limited supplies and strict compatibility demands. This article will offer practical ideas on what can realistically replace them, suggest solutions, and outline a path to upgrade. It is important to present reasonably cost-effective yet realistic methods to extend the life of aging equipment while developing future modernization strategies when ready for continued changes. In this regard, the concepts suggest continuing to address the primary challenges related to legacy module dependencies and provide solutions to improve network resiliency with minimal operational disruption.

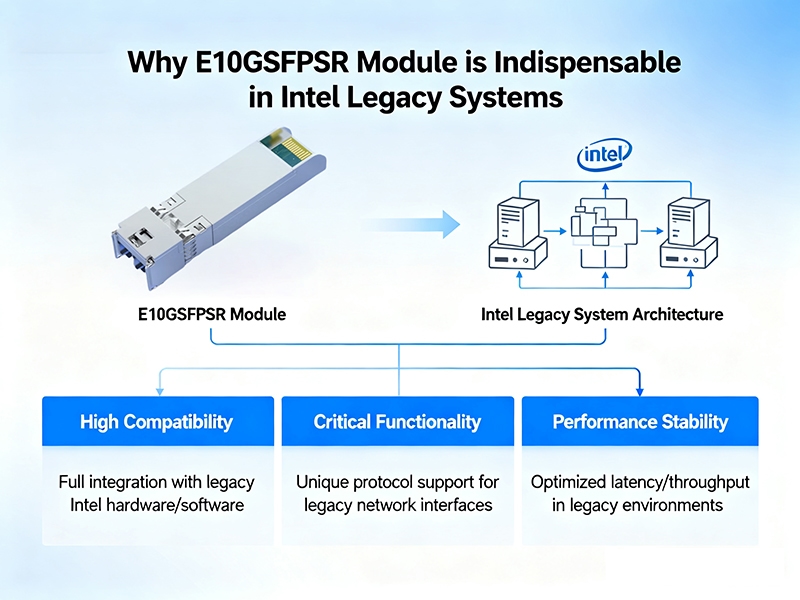

What Makes E10GSFPSR Modules Irreplaceable in Intel Legacy Systems?

E10GSFPSR modules function at an 850nm wavelength and provide signal transmission over multimode fiber lengths of 300 meters. They adhere rigorously to the Intel 10GBase-SR specification. This detail drives consistency with high performance over distances in all of Intel’s previous models or setups. Unlike the generic 10G SR, the E10GSFPSR has Intel proprietary coding that strictly ensures no components outside of Intel legacy firmware will work with these modules.

In other words, the coding will reject any unauthorized module, preventing alteration of stability or security for the network. Also, the revised modules are balanced for power consumption, thermal, and voltage sensitivity as it relates to Intel. The Digital Optical Monitoring (DOM) allows for consistent real-time readings of health metrics, whereas sometimes these are not constant or are omitted altogether on newer modules. With this type of specialized differentiation, E10GSFPSR modules are now deeply embedded within the Intel architecture, where replacement modules cannot simply be swapped without losing integrity or performance.

The Wall Street Trading Floor Crisis: When E10GSFPSR Shortage Stopped Financial Transactions

The Wall Street Trading Floor Crisis: When E10GSFPSR Shortage Stopped Financial Transactions

A high-frequency trading company faced a crisis in their network precipitated by a number of E10GSFPSR modules failing. Because Intel no longer produces these modules, the company had to scramble to procure other modules in the middle of its busiest trading time. This loss revealed vulnerabilities in the supply chain caused by the company’s reliance on proprietary, vendor-coded modules. Because of the emergency situation, procurement during that time was extremely expensive, with some modules being procured at 200% of the original price of individual modules.

Loss of over 12 hours of downtime jeopardized tens of millions in trading revenue. When the company attempted to leverage other modules to get the system up and running, those non-certified modules exhibited erratic network behavior, resulting in additional operational risk. This series of events illustrates how a radical failure of electronic equipment, such as an old SFP module, can cause operational paralysis of the financial infrastructure in which it is used. The importance of proactive legacy management becomes clear through such critical scenarios.

Why Modern 10G SR Modules Trigger “Unsupported Transceiver” Errors in Intel Systems?

Older Intel adapters, such as the X520 and X710, have rigid firmware-based checks to confirm module authenticity. The firmware checks the part numbers, vendor information, and usable parameters against what is approved by Intel. Generic 10G SR modules cannot pass these checks because they are not coded with Intel’s proprietary code. The checks work like a lock that can only be opened with a specifically cut key, and any devices that do not match are rejected. Even if someone were to try to bypass this firmware check, the consequences are usually severe: the hardware may be damaged, warranties will be voided, and network activity will be unreliable. In addition, the patches people put in place rarely last long in terms of compatibility or security. Intel’s firmware, then, is both a security barrier and a gatekeeper to ensure compatibility with permitted hardware and to preserve the legacy of devices in their network.

How to Source Authentic E10GSFPSR Modules in Today’s Market?

How to Source Authentic E10GSFPSR Modules in Today’s Market?

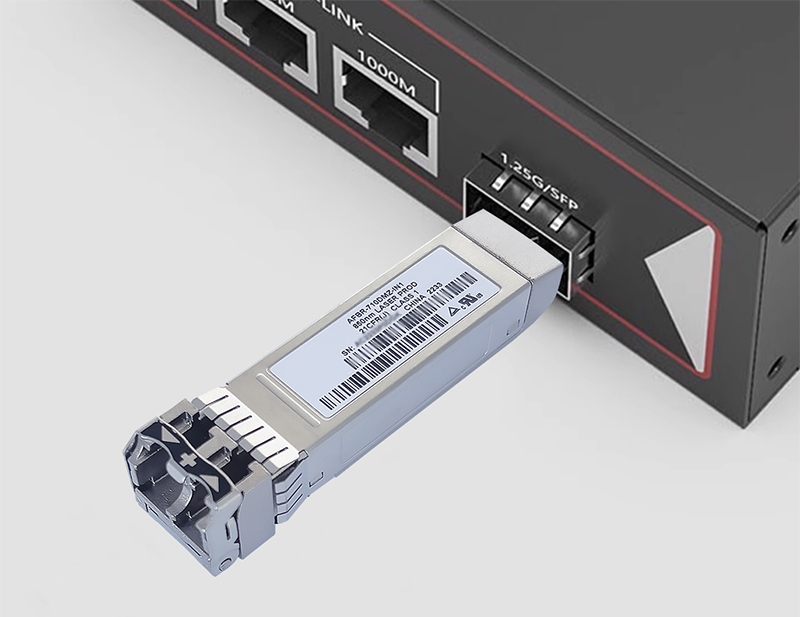

When seeking authentic E10GSFPSR modules, a distinction is made between aftermarket modules that are marketed as just Intel-coded versus generic modules. Approved vendors may carry modules that closely meet Intel’s original specifications, and they should maintain the original performance and form factor of the options. The remanufactured module may present a cheaper alternative to an original but should still go through a profound remanufacturing process and several tests, including optical power, temperature tests, and tests on DOM functionality.

It is critical to pay attention to industry standards, such as MSA (Multi-Source Agreement) and RoHS (Restriction of Hazardous Substances) certifications, when selecting a module. These standards ensure that the modules meet all electrical and environmental requirements, so that you can avoid incompatibilities or violations. Availability varies on a week-to-week basis. Typically, for lead time, new certified units have a lead time of about 4–12 weeks, and the remanufactured modules are available in 2–6 weeks.

The Emergency Data Center Response: 48-Hour E10GSFPSR Replacement Mission

When a large data center experienced a sudden failure of E10GSFPSR modules it initiated an emergency sourcing process to expedite the replacement. To quickly identify modules that met compatibility standards the team utilized accelerated optical and firmware testing. To mitigate deployment downtime the team planned to perform a phased rollout starting with the most critical nodes in securities and the less vulnerable systems kept in service. The team’s risk mitigation strategy included taking advantage of previously coordinated efforts with the module vendor and expediting shipping through their vendor relationships.

The team also kept an always updated backup inventory of validated modules. This is an example of an urgent legacy migration that emphasized speed, precision, and risk mitigation. Phased deployment strategy stabilized the network through global supply chain delays and created business stability through vendor support and cross team communication.

What Makes E10GSFPSR Modules Irreplaceable in Intel Legacy Systems

What Actually Works: Field-Tested Aftermarket E10GSFPSR Compatibility Results

The standard systematic testing process applied to aftermarket E10GSFPSR substitutes employed optical power measurement to confirm that the signal strength met acceptable Intel specifications. The modules then underwent standardized temperature cycling tests that exposed each module to both extreme heat and freezing cold conditions, simulating the heat and environmental stress of real-world deployment and subjecting them to a period of weight work. Prolonged reliability assessments provided a look into the trends of the error rates and the hardware degradation over the course of several weeks of continuous use. In terms of risk mitigation, the organization established in-lab procedures alongside low-impact pilot trials in staged deployments prior to full-scale rollout.

The pilot deployment established protocols for easy fallback to prior operational methods should any incompatibility present itself. After extensive field trials, it was established that several vendors produced aftermarket E10GSFPSR modules that produced reliable operation and exceeded performance in all instances when compared to a generic vendor’s module when installed in an Intel X520 or X710 system. Only those products having undergone MSA and RoHS certification provided acceptable stability. Certification is an important factor in verifying a purchase in the aftermarket space.

When Does E10GSFPSR Dependency Become Financially Unsustainable?

Continued reliance on E10GSFPSR modules can put a company into a financial bind. Prices for scarce spare parts can inflate quickly, procurement studies have shown unit costs exceeding original MSRP between 150-300%. Failure rates increased with field data indicating an increase in downtime incidents (by 25%) year over year due to aging module failures. Cumulative cost from downtime, lost revenues, and customer impact can reach or exceed $1 million a year for mid-cap enterprises.

Concerning total generalized distribution cost of ownership (TCO) including expected equipment acquisition, O&M versus accrued spending over a 3-5 year modern infrastructure investment shows that on the basis of cost alone, replacement is worth the investment. Aging networks have reduced bandwidth and scalability, leading to hidden opportunity costs that can impact time to process transactions or offer options for innovation. Maintenance costs steadily begin to rise as troubleshooting becomes more challenging. When making strategic decisions, companies should include actual premium procurement pricing, failure rate, unplanned downtime impacts, and modernization capex component to find a tipping point at which time it pays to consider replacement over patch or maintenance.

The Manufacturing Plant’s Complete Infrastructure Evolution: From E10GSFPSR Dependence to Modern Resilience

After a manufacturing site experienced repeated failures with the E10GSFPSR, which threatened production control, an extensive risk assessment was made to weigh the cost of emergency repairs against a structured approach to upgrade the system in place. The team associated with the manufacturing site quantified lost production as approximately $500,000/month associated with network downtime. Downtime impacted assembly line production, and on average, repairs to the E10GSFPSR occurred quarterly, continuing to disrupt the operational consistency of the corresponding assembly line. Through a rigorous prioritization process and consideration of the longevity of critical systems, the leadership team engaged financial planners to outline a two-year phased modernization plan.

Secured distribution for the budget across two years included a $2 million modernization plan, phased within annual budgets, tied to a production calendar to mitigate the risk of disruption during peak production downtimes. A structured management approach to risk informed the precautionary acts of maintaining emergency spares, vetting a handful of alternative vendors, and implementing purposeful testing pre-deployment. This was undertaken in advance and continued as part of the engineer’s upgrade to renewed infrastructure. The result of this strategic migration was a successful balance of uninterrupted operation with infrastructure renewal, which ultimately yielded a 40% improvement in overall network uptime in just twelve months.

How to Build Vendor Independence and Future-Proof Against the Next Legacy Module Crisis?

Establishing vendor independence begins with thorough inventory audits to uncover which segments are critical and dependent on E10GSFPSR modules. Next, prioritizing replacement modules using risk heat maps can reduce unplanned failures. Budget planning should reflect the coordinated operational need for high-performance optical modules, with a long-term focus on replacements for legacy infrastructure. Moving toward vendor-neutral 10G SR modules will limit the risks of lock-in created from proprietary code with optical module vendors.

Further, adhering to industry compliance based on MSA and RoHS standards will simplify the integration and regulatory compliance of those environments. As a way to be proactive, organizations should develop a multi-vendor strategy, maintain adequate safety stock inventories, and develop scheduling around regular system health evaluations on the infrastructure. These combined strategies will support a resilient and adaptable network architecture, poised to withstand the challenges of legacy modules in the future, regardless of vendor lock-in.

Selection and Upgrade Path Comparison Table

| Indicator | Continue Maintaining E10GSFPSR Modules | Planned Infrastructure Upgrade |

| Initial Investment | Low (Parts procurement) | High (New hardware acquisition) |

| Module Procurement Lead Time | 6–12 weeks (scarce parts) | 2–4 weeks (standard components) |

| Failure Rate | Increasing (~25% annually) | Reduced (<5% after upgrade) |

| Downtime Cost | High ($500K+ per year estimated) | Significantly lower |

| Compatibility Risk | High (firmware lock, vendor coding) | Low (standardized, vendor-neutral) |

| Maintenance Complexity | High (legacy troubleshooting) | Lower (new support ecosystem) |

| Scalability | Limited (max 10G) | High (10G+ to 40G+) |

| Compliance (MSA, RoHS) | Variable, often lacks updated certifications | Fully certified |

Technical Analysis of 10G SR Standard Parameters

The 10G SR standard primarily works over multimode fiber at an 850nm wavelength, with link distances of up to 300 metres on OM3 fibre and 400 metres on OM4 fibre. The link budget for 10G SR modules is usually 4.5 to 7 dB before you take insertion loss and receiver sensitivity into account. Tolerance for loss is very important, since splicing too much fiber, bending the fiber, or defects in the connector can result in the signals falling below acceptable values. Digital Optical Monitoring (DOM) capability is beneficial for reliability since administrators can monitor the real-time power levels, temperature, and voltage of the fiber. Staying compliant with the technical parameters is necessary for stable 10G SR communications and preventing intermittent link losses, which are disruptive to networks using E10GSFPSR legacy modules.

Emerging Technology Trends and Future Outlook

There is a noticeable trend in networks toward 25G, 40G, and even 100G SR modules as needs for higher bandwidth applications continue to arise. The Co-Packaged Optics (CPO) trend has promise, as it packages the optical module within the switch ASIC packages for improved efficiencies and lower latencies. When upgrading legacy components, you should be planning upgrades for the future that will allow you to hand off easier to this technology; otherwise, you will not remain competitive.

Conclusion

Balancing technical awareness of E10GSFPSR infrastructure sustainability with immediate supply challenges and planning for implementation can define your next steps. A layered approach that combines an understanding of the vulnerabilities with implementing rapid emergency fixes and deliberate modernization can sustain the operation. Being able to evaluate your risk against the benefits of renewal can enable decisions that provide the best possible network resilience. Keeping the business running has to happen with proactive legacy management that considers how evolving technology and financial realities are integrated.

The Wall Street Trading Floor Crisis: When E10GSFPSR Shortage Stopped Financial Transactions

The Wall Street Trading Floor Crisis: When E10GSFPSR Shortage Stopped Financial Transactions How to Source Authentic E10GSFPSR Modules in Today’s Market?

How to Source Authentic E10GSFPSR Modules in Today’s Market?