LC-LC Fiber Optic Connectors: A Complete Guide with Tips, Comparisons & FAQs

The LC-LC fiber optic connector is the cornerstone of today’s high-performance fiber networks, particularly in data centers and telecommunications. LC-LC connectors are a popular type of connector because of their small size and exceptional performance, which allows for high-density fiber applications with small signal loss. Knowing about LC-LC fiber optic connectors is important when upgrading your fiber optic network or designing a new infrastructure.

We will take you through what LC-LC fiber optic connectors are, why they are so popular and common, and how they stack up to other connectors, along with the relevant best practices and helpful hints for choosing and using LC connectors. Next, we will walk you through LC connectors, identify their key advantages, and go through some of the key features.

What Is an LC-LC Fiber Optic Connector and Why Is It So Popular?

The designation LC connector originally stood for Lucent Connector after Lucent Technologies, who designed this very small form factor fiber optic connector to address the trend toward space-constrained and high-density networks. In contrast to several of the older connector types like SC connectors and ST connectors, the LC connector incorporates a 1.25 mm diameter ceramic ferrule, which is half the size of the larger SC connector ferrule.

This smaller ferrule size allows LC connectors to increase the number of connectors placed in a more limited and constrained space, which can be a key driver in modern data centers and telecom networks, especially in the larger space-constrained metropolitan areas.

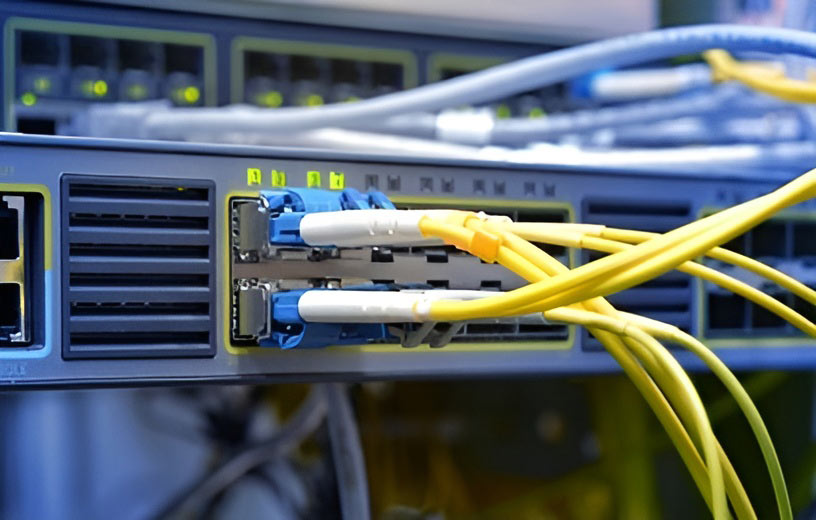

An LC-LC fiber optic cable refers to a fiber patch cable having LC connectors on both ends, connecting equipment like switches, transceivers, or patch panels either inside or between floors or applications used to interconnect equipment in high-density networks with low loss characteristics. The LC connector can be engineered for either single mode or multimode fiber depending on the fiber application.

The simple and robust design of the LC connector has also contributed to its popularity with applications. LC connectors have a push-pull latch to provide a secure connection and are easy to insert or remove with no tools required. The reduced size and easy-to-connect or disconnect function can reduce the installation time and maintenance time when installing in high-density applications.

Compared to other fiber optic connectors like SC connectors (where SC stands for Subscriber Connector) and ST connectors (Straight Tip), it is clear to see the LC connector uses less space for the connector footprint and supports higher port density while providing useful optical performance. SC connectors are typically larger and were often used in an older generation of networks that were less dense, compared to LC connectors, which are commonly the preferred connector for fiber applications depending on a space and low loss performance application consideration.

Overall, it is easy to see why the LC-LC connector fiber optic solution is becoming the MOP for many fiber optic applications in this era of fast fiber optic infrastructure.

What Makes LC-LC Connectors Unique? Understanding Their Design and Performance

The LC fiber connector is a popular choice in the world of fiber optics, thanks to its small footprint, dependability, and performance. The LC connector is built around a 1.25 mm ceramic ferrule, which aligns the fiber cores for the best transmission of signals. The size of the ferrule is a quarter smaller than an SC connector’s typical size of 2.5 mm, so the LC connector takes up as little as half of the space as an SC connector.

Because of this, the LC connector is particularly well suited for cramped spaces such as data centers, telecom closets, and enterprise networks that maximize port density.

The LC connector is built out of plastic to make it durable and safe, and the connector latches in such a way as to make the connection secure and snap-in, reducing the possibility of accidental disconnection. The latch is a push-pull design, allowing the LC connector to easily connect and disconnect without any special tools—making maintenance and upgrades hassle-free.

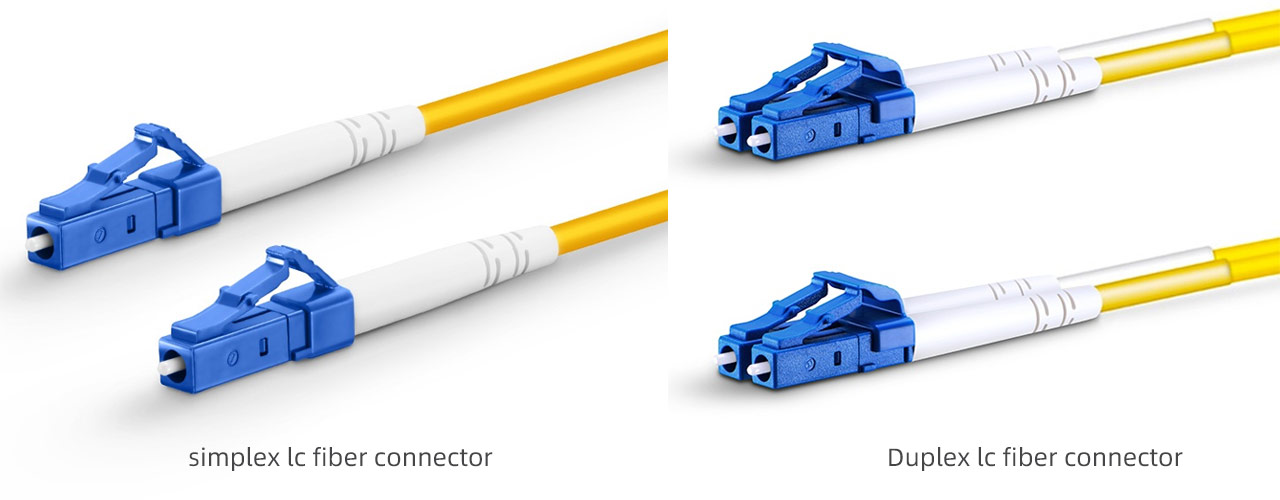

There are two main types of LC connectors: simplex and duplex. A simplex LC fiber connector utilizes a single fiber strand and is used in mostly one-way communication applications, unlike a duplex LC connector, which is two fiber strands in one clip, allowing for two-way communication at the same time. Duplex LC cables are common due to their speed to transfer data back and forth because a duplex LC cable does not require two separate cables to send and receive data.

Another reason LC connectors are so popular is the performance. LC connectors have a low insertion loss (typically less than 0.2 dB), meaning that the signal at the connection is minimally attenuated. LC connectors will often give excellent return loss characteristics (less signal reflectivity), which gives a higher degree of reliability to the networks. LC connectors are rated for around 500 mate cycles, balancing durability and performance.

Whether single mode or multimode optics are used, LC connectors perform consistently. Single mode LC connectors are used for long distances and high bandwidth applications, while multimode LC fiber connectors are more commonly used for distances shorter than single mode with a high data rate, such as within a building or campus network.

In conclusion, fiber optic LC connectors combine compactness, reliable connection, and superior optical performance. In short, the fiber optic LC connector is an increasingly popular connector in modern fiber optic networks where density, reliability, and ease of use are paramount.

How to Choose the Right LC-LC Fiber Optic Cable for Your Network

Picking the right LC-LC optical cable is important to achieve the best network performance and reliability. The first significant consideration is to decide if you need a single mode or a multimode LC-LC fiber cable. Single mode cables are designed with a smaller core size that supports long-distance transmissions with low loss in signal strength. Single mode cables are best suited for networks over large distances such as telecom networks and data centers.

Multimode LC cables have a larger core and are typically used for shorter distances such as in a building or campus-type environment where high bandwidth is required but transmission distance is limited.

Next, you will need to choose between duplex and simplex cables. With simplex LC fiber cables, data is carried in one direction, making them better suited for applications like video surveillance or to connect specific sensors. Duplex LC cables are one cable but contain two fibers that allow for simultaneous, bi-directional communication. Duplex type cables are the common standard for most network applications including Ethernet and fiber channel applications, as they allow for efficient two-way data flow.

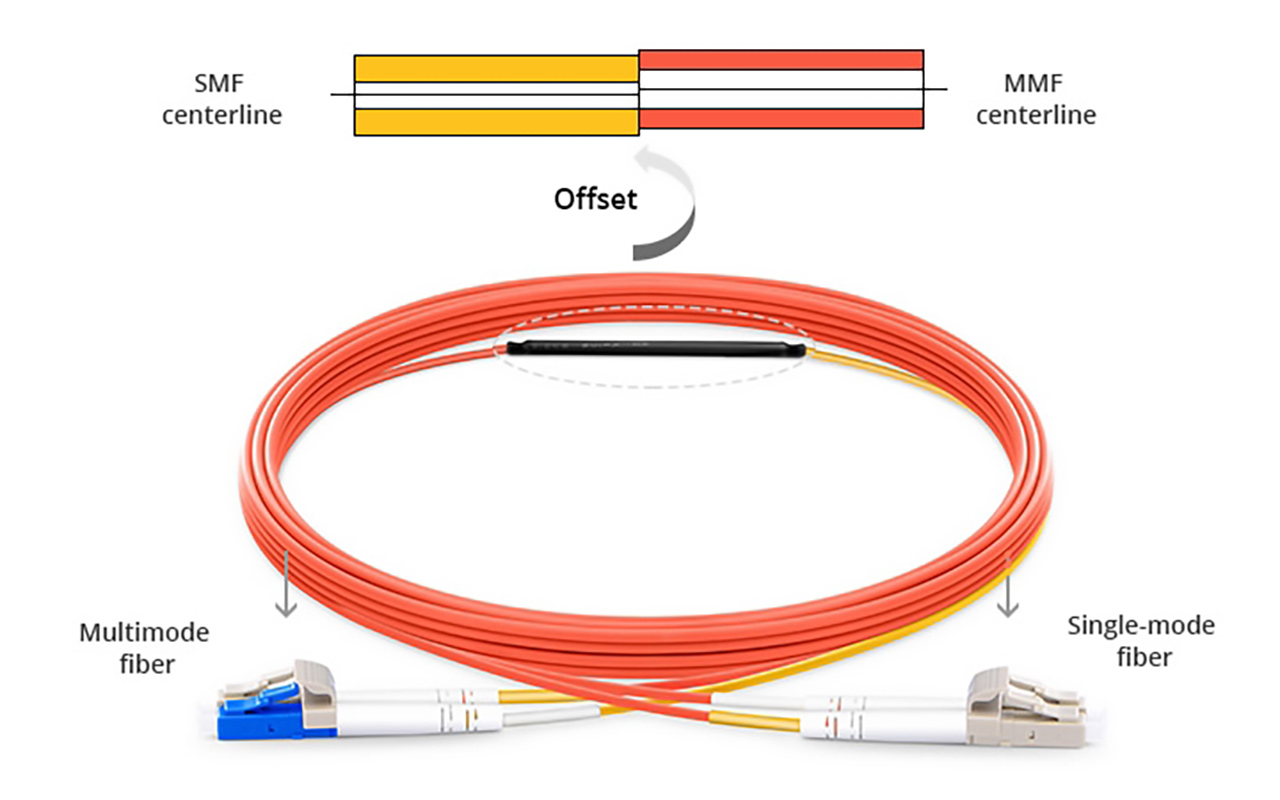

There are specialty cables that can provide added benefits depending on your network and the environment you are connecting to. Armored LC fiber patch cables provide added protection in cases of physical damage, making them ideal for industrial or outdoor applications where the cables may be exposed. Uniboot LC cables combine two fibers into a smaller single connector allowing for high-density cable management while reducing the total bulk in cabling. Mode-conditioning LC patch cables are designed to be used in mixed environments when single mode equipment connects to multimode fiber, to condition the signal and maintain performance.

Another variable to keep in mind is the cable jacket type. Indoor use generally has an LP (low-profile) PVC jacket; however, when you have a plenum space (normally space used for air), a plenum-rated jacket will be required to meet safety codes. Outdoor cables use ruggedized jackets that are less prone to moisture, UV rays, or temperature extremes.

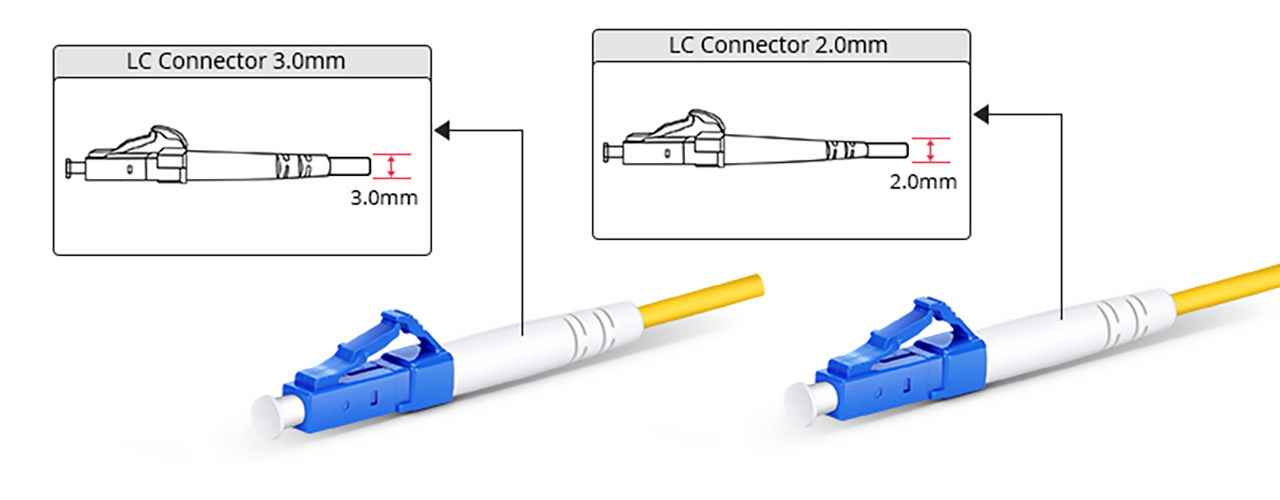

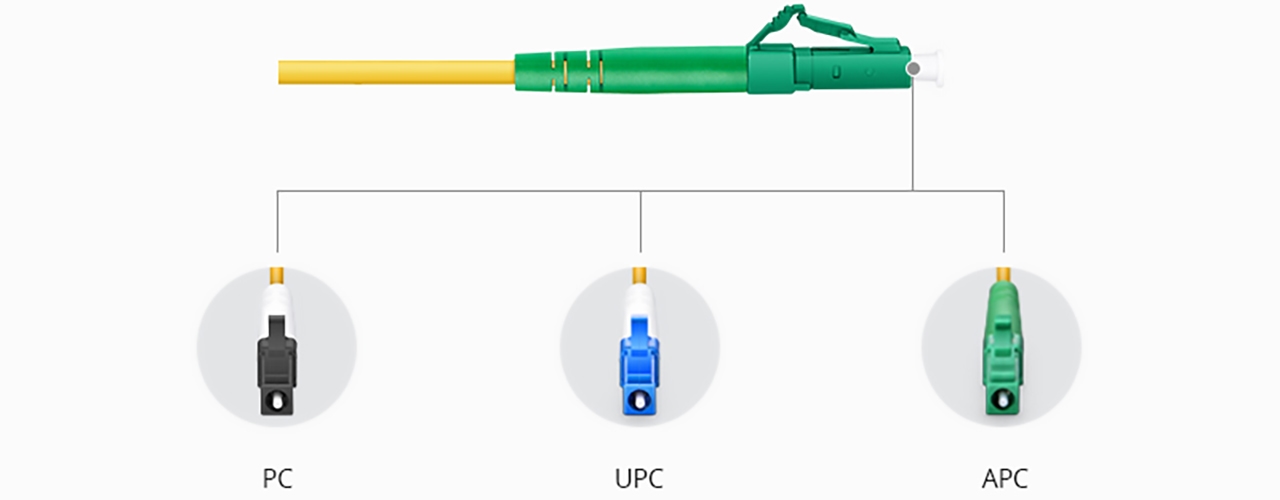

You will also be considering practicalities like the length of the cable, fiber count, and which polish type connector you would like. There are also LC to LC fiber patch cables of different lengths; the fiber count depends on how many fiber connections you are providing. When looking at polish types: UPC (Ultra Physical Contact) and APC (Angled Physical Contact); the choice depends on the return loss acceptable to the application. APC connectors provide better return loss performance and therefore are preferred for most applications involving precision or long-haul connections.

When you’re selecting an LC fiber cable, consider your application: a data center may require high-density, low-loss cables; a telecom network may need long-distance single mode fibers; and an enterprise environment may want the flexibility of durability in options. Consider the cable type with the jacket style and how you would like to connect, and you will be set for performance of your cable in your network.

LC Fiber Optic Adapters, Patch Panels and Accessories: What You Should Know

LC adapters (also called couplers) are an important part of fiber optic networks, connecting two LC fiber optic cables together to transmit data. These adapters allow for the accurate alignment of the fiber cores to minimize loss and maintain network performance. They come in a smaller size, which is great for high-density environments—the LC connector comes in a small form factor, meaning the LC adapters will be the same small size.

There are several types of LC adapters for various applications. Simplex adapters connect single fiber strands, while duplex adapters simultaneously connect two fibers, which is critical for bi-directional data flow. Also, there are simplex and duplex LC adapters for both single mode and multimode fibers.

To help deal with many fiber connections, LC fiber patch panels are often used. Patch panels provide high port density and increased modularity as fiber networks grow. Patch panels also help keep fiber organized as it becomes more prevalent in your environment. Patch panels should be secured in racks or walls, and the LC adapters should be connected to the ports on the patch panel, with cables routed using strain relief to limit damage, which will help simplify maintenance in the future. Being mindful of maintenance and labeling ports simplifies troubleshooting for future expansion as fiber networks become more robust and centralized in one location.

Several other accessories allow LC connectors and adapters to work with increased reliability. Fiber optic attenuators help balance signal strength and can prevent damage to sensitive equipment from too much signal strength. Cleaning kits should be an essential item to have on hand. Even the smallest dust particle can cause major degradation of the signal strength. Specialized cleaning kits include lint-free wipes for cleaning the connectors and a connector cleaning kit specifically for fiber connectors with a 1.25 mm ferrule. These kits are great to ensure proper cleaning of the connector. Pull tabs connected to LC connectors allow for easier removal of the connector from the adapter without damaging the cable or connector.

LC connectors and adapters can also connect seamlessly with transceivers and media converters using LC type interfaces. Transceivers and media converters convert (or transfer) optical signals to electrical signals and vice versa. Also, transceivers and media converters allow existing (or needed) connections between technology segments using optic and electrical signals. Using the compatible LC adapters and/or LC patch panels ensures that the fiber optic infrastructure can be reliable, scalable, and manageable.

LC vs SC Connectors: Which One Should You Use?

When selecting fiber optic connectors, it is necessary to know the differences between LC vs SC fiber connectors in order to get the best performance and the most use out of a small space for your network. The most apparent difference is size. An LC connector has a 1.25 mm ceramic ferrule, almost half the size of an SC 2.5 mm ferrule. This smaller size is one of the reasons the LC connector has a higher port density, and because of its piping, it is ideal for cramped spaces such as data centers and telecom racks.

Similar to their size, the locking mechanisms are different. LC connectors use a latch locking mechanism, like an RJ45 Ethernet plug, to securely connect and safely disengage the connection. An SC fiber connector has a push-pull mechanism that is durable and easy to operate but uses more physical space. Because of the differences in locking mechanisms, LC is typically easier to use in an enclosure, and LC offers enhanced stability with connections in high-density design.

Both LC and SC connector performance are similar to each other in terms of insertion loss and return loss, as neither typically experiences a loss greater than 0.25 to 0.5 dB. Both can usually be relied on for a low signal degradation connection, however, in terms of performance, it is noted that SC has a longer mating life cycle (approximately 1000 cycles) than LC (around 500 cycles).

Cost is also a factor. SC connectors are more cost-effective, due to their simplicity of design and longer existence in the markets, whereas LC connectors are more costly due to their high-density design. Although LC may cost more, whether it be a small price increase or a more significant price increase, the trade-off of space and high density is often worth this small investment in environments with high density.

Typical use-cases will differ: LC connectors are often used for high-density telecommunications and applied in common data center spaces where developers have to try to increase the maximum of connections through the common data center problem of space. Like LC, the SC fiber optic connector is used in general-purpose networking and often is deployed for residential and enterprise applications, where handling it is more relative than the cost.

If you find the need to utilize both fibers, you may find LC-SC adapters or hybrid cables that would allow you to connect either together, and seamlessly interconnect both LC and SC fiber optic systems without sacrificing performance.

In summation, you may consider LCs for compactness and high-density applications, as well as SC for cost-effective general-purpose applications. Understanding these variants and differences in LC vs SC can make a significant difference when utilizing fiber optic connectors based on your respective network needs.

Installation and Maintenance Tips for LC-LC Fiber Optic Systems

Proper installation and maintenance of fiber optic systems with LC connectors is essential to optimal network performance and system longevity. Careful handling of LC connectors is the first step to avoid damage. Dust caps should be removed only when you intend to make a connection. Avoid contact with the LC fiber end or the ferrule. An oily or dirty finger can reduce signal quality.

Cleaning is very important for reducing signal loss. Always use an LC fiber optic cleaning kit qualified for the small 1.25 mm ferrule used for LC connectors to clean these devices. For routine maintenance, dry cleaning with lint-free wipes or a dedicated cleaning stick will remove dust or dirt and is very effective. For more stubborn contamination, wet cleaning with a designated fiber optic cleaning solution, followed quickly by dry wipes, will restore the clarity of the end-face of the connector. After cleaning, always inspect the connector with a microscope to ensure no residue remains.

Proper cable management with the LC cable will help maintain the minimum bend radius, preventing microbends or macrobends that will cause attenuation. Always put your cable in a cable organizer and avoid tight bends or excessive pulling forces on the LC fiber patch cord. Properly routed and secured cables will relieve stress and maximize cable life.

Polarity management with duplex LC cables (Type A which is straight-through, and Type B which is crossover) is important. Polarity management avoids communication errors in a bidirectional link, so attention must be paid when using LC patch cord polarity reversible cables (e.g., uniboot). Verifying polarity before the installation of functionality will reduce complications with future network troubleshooting.

There are common issues you can expect with these connectors, such as dirty connectors themselves, misalignment, and damaged ferrules. The most common issue that leads to signal loss is a dirty connector. Fortunately, the process to clean dirty connector ends is straightforward. Misalignment is usually caused by applying excessive force to the connector or incorrect seating of the LC connector into the adapter. It is always good practice to hear or feel a “click” when pushing the LC connector into the LC adapter. Finally, if you visually see a damaged ferrule, the cables must be replaced to restore performance.

Tools for installation and maintenance that are recommended include fiber optic microscopes, fiber optic connector cleaning kits, LC connector removal tools, and cable testers. You can’t go wrong adding and using the right tools to identify and solve the most common issues with the LC connectors before it impacts overall network reliability.

By implementing these best practices and maintenance routines, you can keep your fiber optic cable LC system up and running, low insertion loss, and high network uptime.

Frequently Asked Questions

What is an LC connector and what is its significance?

An LC connector (Lucent Connector) is a fiber optic connector that is described as a small form factor connector that is known for its small size and stable performance. It is critical in a fiber optic network because it provides accurate fiber alignment and low signal loss. LC connectors are critical in high-density applications where space is limited like data centers or telecom networks.

Can LC connectors be used for single mode and multimode fiber?

Yes, fiber optic LC connectors can be used for single mode and multimode fibers. Single mode LC connectors can be used for long distance with high bandwidth applications, whereas multimode LC connectors can be used for shorter distances with high data rates.

How to clean LC connectors the right way?

Cleaning LC connectors properly involves using an appropriate fiber optic cleaning kit that has 1.25 mm sized lint-free wipes and/or cleaning sticks. Dry cleaning is mostly more than enough, but you may need to wet with isopropyl alcohol and follow with dry wiping for hard stubborn dirt. You also need to clean and inspect the connector end face in a microscope after the fiber optic cleaning process.

What causes insertion loss and how do we minimize it?

For LC connectors, insertion loss is generally caused by dirt, misalignment, and/or damage to the fiber ends. To minimize insertion loss, you will need to keep the connectors clean, maintain proper mating of connectors, and not stress or over bend the fiber cables.

What are the differences between simplex and duplex LC connectors?

Simplex LC connectors use a single fiber strand for one-way communication, while duplex LC connectors have two fibers installed in one clip to enable bidirectional data transmission. Most networking applications will use duplex LC connectors.

How can you tell if an LC connector is dirty or damaged?

You visually inspect the connector with a fiber microscope to see if any dirt, scratches, or chips are present on the ferrule. Dirty connectors degrade the signal while damaged connectors will need to be replaced so that the network will perform appropriately.

What tools do I need for LC connector installs?

Basic and necessary tools include fiber optic microscopes, cleaning kits, connector removal tools, and a cable tester. These tools help with the installation of fiber optic cable LC systems, or when troubleshooting them.

This FAQ section serves as an overview for frequently asked questions regarding fiber optic LC connectors. A better understanding of LC connectors can help you take care of your fiber optic network in the future.

Conclusion

LC-LC connectors have become essential components in fiber optic networks today. Their small form factor and compact size allow for high-density connections to be highly effective, especially in limited space environments like data centers and telecom closets. In addition to being a space-saver, LC connectors also perform well with low insertion loss and high return loss, keeping the signal stable and efficient.

They are utilized in a wide range of networks from large data centers, telecommunication backbones, and enterprise LANs to meet the need for faster and more scalable fiber optic systems. Their capability of utilizing single mode and multimode fiber only furthers their universal application in differing network scenarios.

When you purchase LC-LC fiber optic solutions, you are also investing in a future-proof solution for your network. If the bandwidth requirements have increased or if the network has changed from its last upgrade, you will maintain high port density without sacrificing performance in the end. LC connectors provide a scalable, efficient foundation that can help support technology changes and network expansions.

For anyone wanting to build or upgrade a fiber optic network, it makes perfect sense to use LC connectors when possible. The various factors such as space, durability, and optical performance of LC connectors are the backbone of modern fiber networks, ensuring the infrastructure is built strong and ready for the next-gen technology.