How to Buy Reliable Fiber Optic Patch Cords in 2026: Skip Amazon Fails and Supplier Scams

By late 2026, many engineers operating 800G or 1.6T links reported that packet drops or congestion were causing major disruption to operations during peak evening hours when there is a high amount of activity. Instead of checking the switches and light modules as soon as they encountered these problems, they were forced to check several things, only to find out later that the $5 online-purchased patch cord was actually the issue that caused delays. When engineers use low-cost cords, they always fail because these cords cannot withstand the amount of heat a large number of connections create or the stress of plugging and unplugging multiple times. So, in order to continue operating smoothly and without interruption, engineers should always require documentation of proof from suppliers regarding the specifications of all products before placing orders.

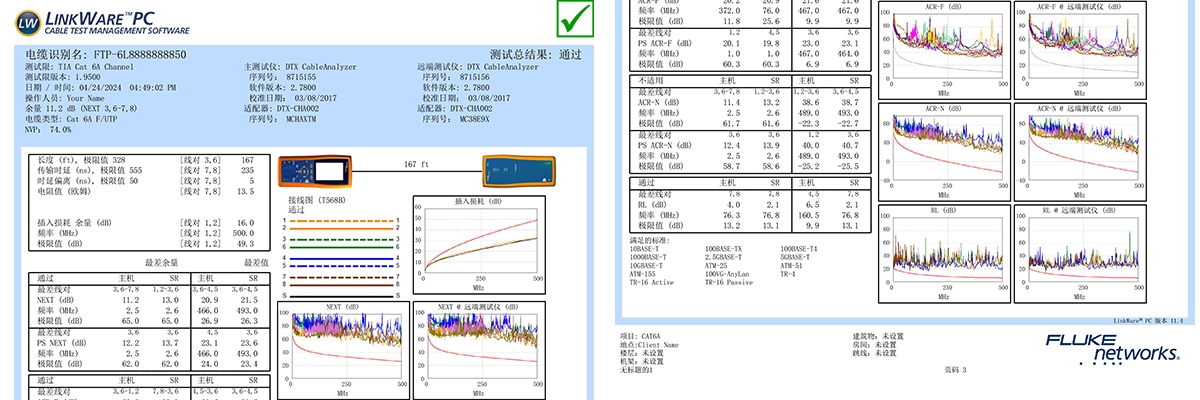

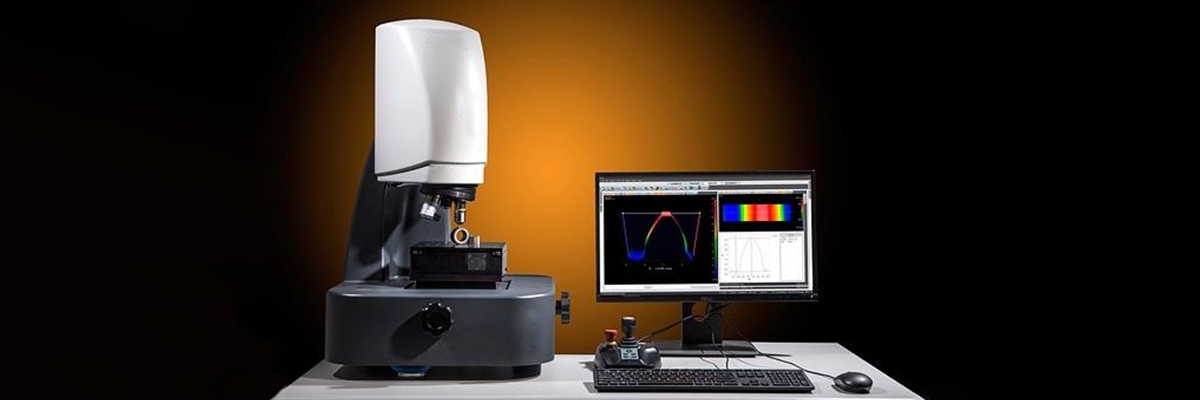

This ensures that every product sold by a reliable vendor will provide the manufacturer with satisfactory documentation to support their claims. Documentation typically consists of test results that measure ferrule apex offset to be less than 50 nm, ensure that fiber height is within±100 nm of the manufacturer’s specification, and determine end face radii between 7 mm and 25 mm using standard measurement tools. Once the documentation from the vendor is received, the engineer simply needs to match the results from the test documentation with the specifications provided by the manufacturer in order to be assured that the product will perform well for all users without causing degradation or failure at any point.

You don’t need advanced knowledge of the math to get great performance from these products—you just need to ask for the measurement summary sheets from suppliers, which will give you the key metrics you need to confirm that your fast networks will not suffer from performance drops due to signal drifts. Get confirmation on your measurements before placing a large order, because if you skip this step, you’ll be vulnerable to the production shortcuts that reveal their negative impact during heavy use.

Why My Cheap Fiber Optic Patch Cords Failed After One Night

Why My Cheap Fiber Optic Patch Cords Failed After One Night

Last year, various teams working in a large-scale U.S. Data Center ran into a similar issue while trying to install 400G main lines. While the first bench tests of these 400G systems were all clean, at midnight, after a full load had been connected, the temperature hit close to 40°C. At this point, the error count started skyrocketing due to small amounts of movement within the cheap connectors. The cheap connector cords had inconsistent ferrule heights and poor polish that did not line up well when viewed closely. As a result, when you plugged a flat-ended connector into an angled-ended connector, you created reflections reaching as low as -35 dB, so the links weren’t holding together and there were constant signal retries, causing a loss of capacity. After replacing the non-certified connectors with certified connectors, the signal loss was consistently 0.18 dB with no variation, and the error rate decreased tenfold. After ongoing testing from the supplier over several months, it was proven that high-quality finely polished ferrules have less than 0.05 dB loss after hundreds of connections compared to low-quality ferrules, which wear out nearly six times as fast.

Analysis of surveys by NTT-Advanced Technology indicates that dirt on connector surfaces from inadequate polishing affects 96 percent of network installations and 80 percent of network operations, and that the effects of poor polishing increase with increased heat. The cords that conform to GR-326 also provide the correct amount of connection pressure across their entire lengths, thus providing a stable operating environment with little chance of abrupt failure. This technique has enabled field technicians who have experienced interruptions due to these types of failures to obtain the GR-326 compliance documents before they begin their work and has allowed them to develop procedures that prevent future failures from affecting multiple rows of equipment at once.

Amazon Orders That Won’t Fully Insert or Hold Signal

Amazon Orders That Won’t Fully Insert or Hold Signal

Last month, tech personnel in the City of Chicago suffered through many nights of working with 60 ports due to Amazon’s cords not fully seating properly. The reason for the seating issues is a 2-micron misalignment on the external face of the connector, which causes the light to not be distributed evenly over a total of 800G of light path, even though it appears to be a good connection by checking the initial power readings. When the connector is not seated properly, it generates a false signal that disrupts the detection units and, therefore, reduces the overall speed of the process, even when the setup looks good. As a result, instead of adjusting your systems to achieve optimum performance, you continue to make adjustments at that point. Manufacturers of quality products usually provide 400x magnification photos of the connector’s face prior to shipping so that you can see the uniform shape of the dome and see exactly where the light will be distributed; if your supplier does not provide this, it is likely that they are manufacturing their connectors using shortcuts.

According to EXFO reports of active sites, the most common causes of failure in data facilities are connector damage and excessive buildup. Therefore, it is essential that you obtain these photos before installation as they help ensure a smooth fit and will not result in lengthy repair timeframes. Workers who utilize the verification of these images have noted no repeat adjustment, and thus the images reveal specification defects prior to impacting functional hardware.

As seen under 400x magnification, the minor imperfections (scratches and pits) on the mating surface will become deadly very quickly with the rapid increase in 1.6T light, becoming burn spots and breaking contact within days. Since inexpensive ferrules conceal these types of defects, the pre-shipment photographs will enable you to reject the defective ferrules and maintain the integrity of your connections.

The Hidden Downtime Costs of Cheap Patch Cords

The Hidden Downtime Costs of Cheap Patch Cords

| Amazon Budget Cords | Certified Brand Cords | |

| Typical price per cord | $5 | $15 |

| 100-unit purchase cost | $500 | $1,500 |

| Average failure rate (3 years) | 10–12% | 1–2% |

| Downtime cost per failure | $3,500 | $0 (prevented) |

| Engineering overtime (per event) | $450 | negligible |

| Three-year total cost of ownership (TCO) | ≈ $80,000 (including outages) | ≈ $8,200 |

For a mere $5 for a single cheap cord, it is easy to overlook how this could cause you to spend thousands of dollars on your business due to downtime ($3500 lost revenue) and the added costs of employee overtime ($450 on average). Consider that your $500 purchase of 100 cords could cost you approximately $80,000 if each incident caused by cord failure resulted in three years’ worth of lost time. A certified cord option will cost you $15 each or a total investment of $1500 to purchase, yet you’ll have a breakdown rate of 1-2% and virtually no major interruptions in business operations. This means your entire cost of ownership would be $8200 versus $80,000 for the budget cords since they eliminate the domino effect of cord failures.

In 2025, data from large U.S. data centers indicate that while many inferior cords will fail between 10-12% due to material swelling in the higher temperatures generated by more intensive AI workloads, superior cords remain intact. To determine how much money you could potentially save from initial discounted prices that eventually transform into major over-spending, use a specific number from your operation and calculate the accompanying costs. As long as certified cords that are compliant with LSZH OFNP are used, it allows you and your employees the ability to focus on future growth rather than emergency response. While a short-term agreement to save money may seem like a smart idea initially, if you don’t take into account the full lifespan of your investments, many times the problem will become one that needs to be solved long-term.

Decoding Specs Before the Shipment Arrives

Decoding Specs Before the Shipment Arrives

By using the signal loss limit of 0.25 dB and the return loss of -55 dB as criteria for connection calculations for 400G or 800G main paths, users will be able to ensure that the entire connection series exceeds a maximum signal loss of 0.90 dB. Since even small amounts of signal loss will increase the frequency of overloading chained connections, it will be beneficial for users to include the complete cables/codes when placing their orders. For example, for orders of 5m long LC-APC to LC-UPC OM5 50/125 LSZH OFNP cable, users should include both of these connector designs in the item codes section of the order to ensure that there are no discrepancies regarding the inventory.

In the case of multimode installations, anything below the minimum distance of 150m needs to use true wideband products that have a maximum capacity of greater than 4700 MHz- km to perform better in terms of wavelength mixing; for single-mode installations, users will need to use OS2-rated products with 1310 nm and 1550 nm wavelengths.

According to the Telecommunications Industry Association (TIA), the maximum allowable signal loss on any cabling connection is 0.75 dB, although high-end cabling can achieve much lower losses (0.15-0.2 dB) to achieve a high degree of professional stability. By incorporating these limits into any contract for items being purchased that are to be shipped, a responsible manager will avoid any disputes regarding the details of the products being purchased. This demonstrates that a detailed ordering procedure provides customers with assurance of quality up to the date that the products are received.

What IL and RL Mean for Real Networks

Link signal loss indicates how much light is dissipated due to scattering or absorption, while Return Loss provides a measure of the percentage of Return Loss light returning towards the start point. Because both of these measurements can impact overall performance (and because of the extremely short time frames found with data transmission), if you have a very large increase in loss of 0.25 dB, the amount of available headroom will diminish very quickly. Group-level certification is superior to using simple averages, as an average can be influenced by batches with loss rates of up to 0.18 dB and Return Loss levels of -60 dB due to good shaping and plating; shifts of 0.4 dB or more indicate twisted edges or reshaped components. Skin oils reduces Return Loss levels by 10-12 dB compared to standard, while minimally impacting loss levels. This can be detrimental to precision and accuracy during high-speed data transmission.

When cleaning surfaces for defect detection, always validate the results pre-completion in order to avoid unknowingly discarding items that were not properly processed. All groups that require individual measurements will launch without delay and provide you with a seamless transition from high-risk to standard operation.

How to Read a Real Fiber Cord Test Report

How to Read a Real Fiber Cord Test Report

Drawbacks and potential reworkings should be addressed at both ends of a production cycle. For example, if a manufacturer uses good-quality tools, the outcome can be a long-lasting product; however, if the manufacturer has poor-quality tooling, the product will exhibit quick failure. Any vendor that offers the ability to verify the actual product onsite via a QR Code should be used for this purpose, as it will significantly reduce the amount of time and effort needed to verify the manufacturer’s integrity. Do not trust shiny documents without photographs, as the images and the content of such documents may not be the same. True production summaries include all photographs with a date of manufacture, end serial numbers (if applicable), and the accepted tooling for the offset apex, radius curves, and defects. In addition, level surfaces indicate quality and long-lasting performance, while uneven surfaces indicate potential issues.

It is easy to spot a counterfeit by using a low-intensity light source to shine through the end of the tool. Counterfeit tooling will have a spotty appearance and will contain multiple cords that are manufactured in the same pattern as the legitimate summary. A counterfeit tool will have many duplicate cords if multiple cords were used to make it. In the year 2026, counterfeit tools will be supplying the market in mass quantities. 400 times the amount of these tools will be verified based on the seller’s inventory sheets, enabling verification of all reworked counterfeit tooling. All counterfeit tools can be identified by using both the manufacturer’s production sheets and their employee’s verbal discussion to identify the signs of counterfeit manufacturing.

3D Geometry: The Invisible Reason Some Links Live Longer

Light paths should be aligned with the closest possible overlap at the center peak of the light path within a few tens of nanometers from the center peak. When there is a 50 nm misalignment of the light paths, the resulting force on the light paths will not be even enough during thermal cycles, causing a gradual accumulation of product defects after several cycles. The vast majority of current imaging technologies will allow for a single imaging of all lights in a matter of minutes, which indicates a manufacturer’s significant oversight regarding the final deliverables of the product; refusal on the part of manufacturers to provide information fits this pattern and indicates that manufacturers may be attempting to hide issues with the product’s formation. 3D imaging creates a defined boundary for your organization.

The proper spacing between the center of the light path and that established by the GR-326 Standard should always be no greater than 1 micrometer to ensure correct light path positioning and minimize damage to the light path that may occur due to high-temperature degradation over time. Because of this, the GR-326 Standard can be used as a reference point for any joint repairs or “welds” so that the proper joint has been created. Therefore, all manufacturers who follow this process will not experience any joint failure, and as a result, you can expect that product reviews will produce significant reliability improvements.

Why 500 Mating Cycles Beat 100 in the Real World

Why 500 Mating Cycles Beat 100 in the Real World

Cords experience physical stress through their regular use, but using cords with ratings greater than 500 will limit any loss due to component swaps to less than 0.05 dB, as opposed to 0.3 dB after several dozen use cycles for low-end rated cords. Forward swap procedures eliminate the occurrence of stopping work to perform a refresh on the cord with a forward swap.

A cord’s wear and tear would be approximately that of a standard cord after it has been through 1,000 connect/disconnect cycles, and since standard cords wear out so quickly, the use of cords that are rated higher than 500 with an extended number of connect/disconnect cycles eliminates the potential for cord failure as a cause of equipment failure. Busy facilities are also able to continue to utilize an air-monitoring system without extending their downtime on-site.

Acceptance Testing: Always Before Deployment

When receiving a shipment, randomly sample 10-15% of shipment items with a Power Checker or Loss Kit at a loss level of less than 0.25 dB, and view each item at a minimum of 400X. Also, check to see if there is any bounce back over the -55 dB limit. If anything is found to be defective, the seller should replace the item immediately, as this procedure is agreed upon prior to purchase confirmation, thus limiting any conflicts due to increased seller confidence in shipment quality. Make this a standard procedure for future shipments as it provides additional efficiencies in managing incoming shipments.

Using a 1.6T MPO-16 connector, test each of the 16 paths individually; one faulty connector ruins all of them. Therefore, you must have a method of checking the cleanliness of the connector face before connecting to it, as the manufacturers recommend cleaning prior to connecting. The orientation of the 16-path MPO-16 connector can change completely after the connector is installed. To avoid problems with orientation changes from occurring, you must check your connector installation configuration and verify that your connector’s orientation is correct prior to using it. Wide-field viewing tools must be used to view all of the connector end views.

Aligning a 16-path MPO-16 connector is more challenging than aligning traditional two-path MPO connectors. Additionally, low-budget suppliers typically cut corners when it comes to installing push-in force on MPO connectors, which means loose connections may lead to problems due to rack vibration. Therefore, you should always check the stability of a connector’s engagement before fully installing it to ensure reliable, multi-path performance without lane crossover.

Bulk Sampling and Vendor Refinement

Sample packages exceeding a quantity of 100 should be tested over multiple layers of the package; resample packages if they exceed 3% defects and recheck/remake them again, creating review cycles resulting in 99.5%+ approvals. By allowing sellers’ on-site input to enhance their product offering, every seller provides periodic monitoring of the best sellers, allowing for the creation of additional dependable lines. The above methods guarantee the delivery of dependable products at an accelerated rate.

Fake OM5 Fibers: A Growing Risk

Corning and OFS manufacturers have produced and distributed 1.6T compatible MPO-16 cleaning materials based on original specifications. However, many of the manufacturers have created their own versions that do not perform as intended. When inspecting the original materials for quality, it is imperative to look for any flaws, as the materials will not work correctly if they are missing or compromised. A poor-quality product will result in problems at the 400G wavelength mixes and will cause spread and accuracy failures. When determining whether a product is genuine, it is essential to check the original sheets and lot marks contained on the product. If the color of the lot marks is different from what is listed on the lot sheet or if the lot marks are not present, it indicates that the lot was manufactured with reworked materials. When inspecting MPO-16 cleaning products, it is crucial to perform a thorough visual inspection to ensure that the product is free of contaminants and properly cleaned. Many sellers will make numerous claims about their products; however, you must perform your own inspections to ensure that the product meets your expectations.

Amazon’s Hidden Recycling Stream

Amazon’s Hidden Recycling Stream

The bottom of Amazon’s Batches & Rework Scrap are finding themselves with Bond Marks, Bond Quality issues post-shipment, resulting in 72 percent of the groups being D.O.A. because of Order Errors or 14 dB escapes. In addition, it is recommended to provide Batch Summary Emails before Transport in the event of a defective shipment arriving at its final destination. A complete record of all packages shipped from the warehouse will eliminate all suspicion related to counterfeit shipment. The number of Finger Marks, or the amount of Bounce, will increase tremendously during laboratory testing, and this finding is consistent with these problems. However, please choose with caution.

2026 Supplier Matrix: Speed, Defects, and Strengths

Elite Corning, with Panduit, produces approved products that can be found on the individual pages of their websites. Each product has a unique 3D image for tracking. Elite Corning’s products are intended for the installation of critical mains and do not permit any flaws. FS/ProLabs can supply stock quickly to support large volume rollouts; however, you should confirm 10 percent of the stock since the reports often differ. Elite Corning’s products also provide high-stakes opportunities with strong support for U.S. quantities. Various products are available from Amazon only. The most significant difference between these Amazon products is how many converted misfit products will have the opportunity to be extensive and generate huge profit margins in relation to trial products at a rate of 1.6T.

Supplier Matrix

| Supplier | Average US Delivery Time | Lab Rating (2025 Audits) | Strengths in 2026 |

| Corning | 4 days | A+ | Longest lifespan, enterprise-grade polish |

| ProLabs | 36 hours | A | Fastest global dispatch, polarity-verified MPO data |

| FS | 3 days | B+ | Scalable bulk orders, strong US support |

| AddOn | 2.5 days | A- | Custom configurations, reliable edge performance |

| Flexoptix | 24 hours (EU) | A | Rapid European delivery, hyperscale precision |

Combine wisely: Corning for mains, ProLabs for emergencies, FS for quantities—info-driven variety prevails.

Reinforcing Accountability Through Purchase Orders

Order by sets (0-3 days) of loss/bounce limits, allowances for redos if more than 3% exceed 0.28 dB loss or drop below -52 dB bounce, prepaid for corrections in a week. This converts the complaint to advancement, so experts generally consider them routine. Enforce initially. Also, apply to MPO layouts and cleaning methods, since the 2026 MPO-16 requirement for use-ready products without rework due to the crowded nature of MPO-16 connectors.

Extending Service Life in the Rack

Monitor connection count labels using reflective tools bi-monthly to maintain 40% to 50% moisture levels and prevent sheath breaks; also, loop slack that exceeds 30mm. Use face wipes to protect the device from wear and tear, use gentler bindings to keep your device safe, and airflow to create twice the amount of working span; do not change devices or fade. The above practices will ensure your specifications are achieved. When the temperature exceeds 40 degrees Celsius, the ends of creep move by nanometers, causing the reflection to increase. Monitoring a connection count connected to a loss panel will give a warning before an emergency call occurs. Deploy creep throughout the racks to eliminate the urgency of upcoming calls.

Polarity and Thermal Stress: The Silent Rack Killers

The MPO has incorrectly allocated capacity to its main bundle (A-C exchange) paths and thus has reduced capacity without prior notice. However, in setup, both layout and marked holders show that this is correct. The only downside to having 1.6T crowding is not being able to see isolated faults as quickly; steady practice will reveal them early on. The MPO-16 does not allow for the cleaning of liquefied materials, which can contribute to gap loss. Height and distance between panels appear to stretch a nanometer due to the density of contact between panels. Recordings will be used to predict rather than to take into account the actual situation on racks.

Summary

The total cost of certified cords is three times higher than unregistered cords; however, because they have a significantly higher average uptime, they are far superior alternatives to the cost reductions of possible hunting at 2 a.m. away from home ($5 purchases). In order to ensure proper lighting levels for large-scale 2026 projects, it is imperative that the end user purchase certified cords before they use unregistered cords.

Reference Sources

- Fiber-optic patch cord – Overview of Fiber Optic Patch Cords, construction, and typical use in telecom and data networks.

- Patch cable – General definition of patch cords, including electrical and fiber-optic variants used to interconnect network devices.

- Fiber-optic cable – Explains optical fiber cable structure, attenuation, and advantages for high‑bandwidth transmission.

- Optical fiber connector – Describes connector types, polishing, geometry, and their impact on insertion loss and return loss.

- IP-16 MPO Connector – Technical overview of high‑density 16‑fiber MPO connectors, including geometry, performance targets, and use in 400G/800G+ applications.

- Telcordia GR-326-CORE – Core performance and reliability requirements for single‑mode optical connectors and jumper assemblies.

- ANSI/TIA-568 – Structured cabling standard covering fiber‑optic performance, topology, and testing guidelines for commercial networks.

Why My Cheap

Why My Cheap  Amazon Orders That Won’t Fully Insert or Hold Signal

Amazon Orders That Won’t Fully Insert or Hold Signal The Hidden Downtime Costs of Cheap Patch Cords

The Hidden Downtime Costs of Cheap Patch Cords Decoding Specs Before the Shipment Arrives

Decoding Specs Before the Shipment Arrives How to Read a Real Fiber Cord Test Report

How to Read a Real Fiber Cord Test Report Why 500 Mating Cycles Beat 100 in the Real World

Why 500 Mating Cycles Beat 100 in the Real World Amazon’s Hidden Recycling Stream

Amazon’s Hidden Recycling Stream