How J Hooks for Cable Help You Say Goodbye to Cable Clutter

In a world where technology is constantly advancing, cable clutter will always be an issue in our homes, businesses, and industrial applications. The growing number of devices and increasingly complex cabling systems means that managing these cables is important not only from an aesthetic point of view but also for managing safety and reliability in any system. Conditioned cables can lead to overheating, noise induction, and fire hazards among other things.

One of the most effective, yet simple, methods to combat this challenge is with the use of J Hooks. These curved supports, shaped like the letter “J,” are designed for you to hold and route cables along walls, ceilings, or inside cable raceways, etc. J Hooks will accommodate many different cable types, including low voltage cable, data cable, and power cable. This is one of the most versatile cable management solutions. The following article explores how J Hooks can be used to help you reduce cable clutter through installation tips, comparing J Hooks with other cable support systems, and their applications across industries.

What Are J Hooks? Basic Design, Materials and Core Benefits

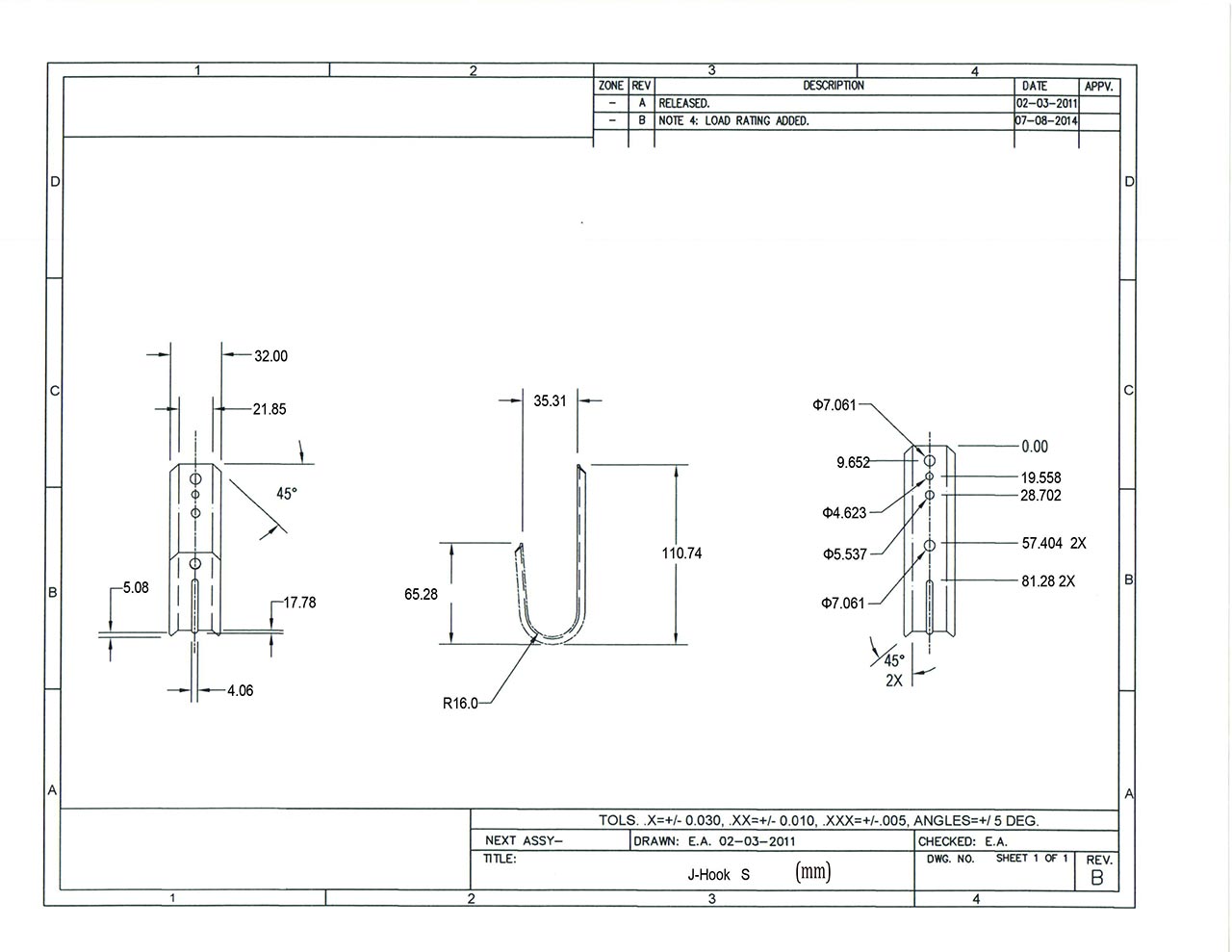

J Hooks are named as such due to their unique but simple shape in the shape of the letter “J,” which easily and securely cradles cables while allowing easier access for adding or removing cables. Also, having an open design to the J Hook eliminates shallow bends to keep the cables inside the J Hook from being damaged.

J Hooks are typically made of 1) galvanized steel, or 2) some sort of durable plastic polymer. Galvanized steel offers strength and a level of corrosion resistance for outdoor or extreme environments, while plastic J Hooks, sometimes called dura hooks, are lightweight and rust-resistant and can be used for indoor applications, while cable bundles are low voltage.

One of the main benefits of J Hooks is their ability to preserve the cable bend radius, which is particularly important for sensitive cable types, for example fiber optic cable, or high-speed data cable. Protecting the cable bend radius aids in preventing damage, extending longevity, and maintaining signal quality.

J Hooks are also simple to install, generally by using j hook screws (included with the hooks) and wall mounts which will reduce labor time and cost.

There are also multiple types of j hooks. For example, j hook screws are designed for fastening j hooks to the wall, j hook wall mounts help support heavier bundles of cables, j hook rebar are designed for anchoring in new construction or from an existing building, and luggage j hooks for easy organizing and loading for travel. There are many types of J Hook for every type of cable management situation.

Comparative Analysis of Cable Support Systems

J Hooks vs. Cable Management Raceways vs. Cable Trays

| Feature | J Hooks | Cable Management Raceway | Cable Trays |

| Cost | Low to moderate | Moderate | Higher |

| Installation Complexity & Speed | Quick and simple installation using j hook screws or wall mounts | Moderate; requires precise fitting and mounting | More complex; involves heavy hardware and longer installation time |

| Cable Protection | Good for maintaining bend radius, less crush resistance | Moderate protection; cables enclosed but limited crush resistance | High protection against physical damage and crushing |

| Flexibility & Scalability | Highly flexible; easy to add or remove cables | Moderate; adding cables requires opening raceways | Less flexible; designed for large bundles, less easy to modify |

| Suitable Cable Types | Ideal for low voltage, data cables | Suitable for mixed cables including power and data | Best for heavy-duty power cables and armored cables |

| Environmental Suitability | Suitable for indoor and some outdoor environments; galvanized steel options available | Mostly indoor use; limited outdoor options | Suitable for harsh environments, including outdoor and corrosive conditions |

J Hooks are an affordable, simple, and flexible way to adhere cables to the ceiling (or ceiling grid) in an office building or data center for low voltage and data cabling. Raceways and trays also provide excellent protection of cables but are more expensive and complicated.

When to Use J Hooks

J Hooks are ideal for tight spaces and for use with mixed cable types, including in the data center of an office building. The open design of the J Hook allows for quick additions or removals of cables. J Hooks are especially beneficial for low voltage cabling. They keep cables at the correct bend radius to preserve signal quality.

When to Use Raceways or Trays

Raceways or trays are used for bundled cables or “heavy-duty” cables (e.g., power or armored cables). They provide better cable protection and segregation than J Hooks, but they take more time and costs to install.

Detailed Example Application Scenarios & Best Practices for Installation

Best Practices for Installations

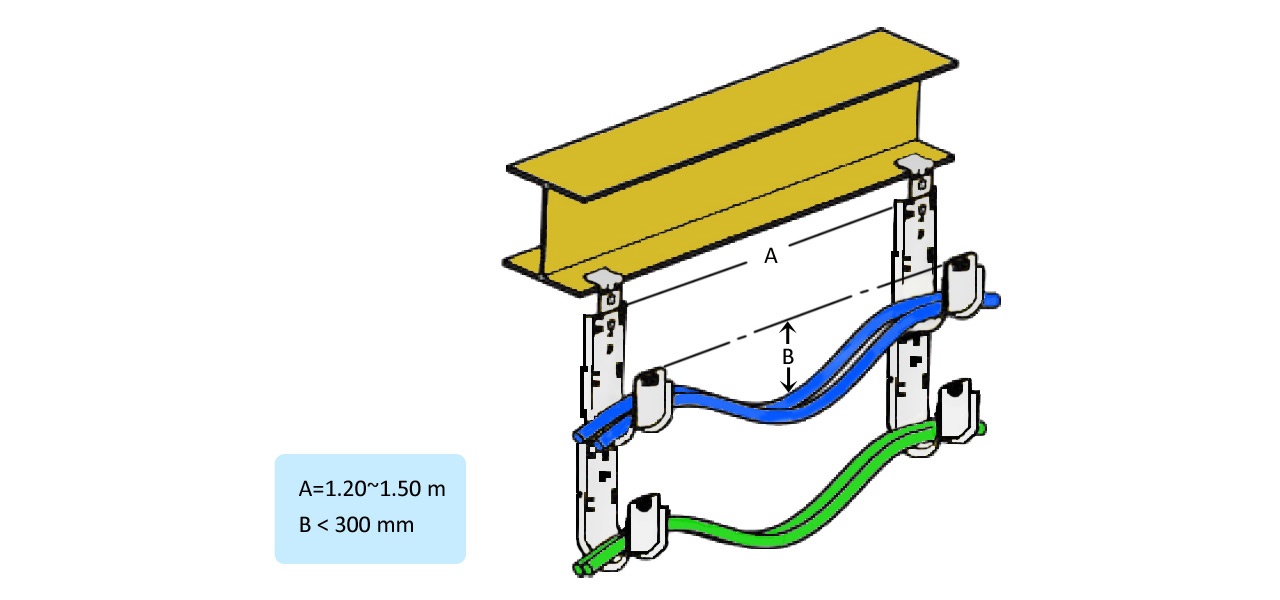

Best practice for installing J Hooks means maximizing the benefits of the hooks. Hooks should be spaced every 4 to 5 feet to avoid sagging or stressing the cable. Exceeding maximum loaded weight limits increases the risk of distortion and cable damage. The design of the j-shaped hanger will also help maintain the bend radius at the proper radius, which is crucial for the signal quality of sensitive cables. Installation with j hook screws or wall mounts helps ensure the hook does not pull away from the walls/ceiling.

Use Cases by Industry

- Telecommunications & Data Centers – cable j hooks are used to arrange delicate network cables to maintain airflow and quality signal traffic

- Construction & Plumbing – rebar j hooks can be used to secure cables to the rebar framework; j hook plumbing can support pipes; tow j hooks are used for large earth moving machinery.

- Fitness Equipment: J hooks squat rack and power rack hooks safely hold barbells.

- Travel & Personal Organization: Luggage j hooks and j hook travelpro provide convenient accessory management.

- Safety & Utility: J hooks for lanyards and small tie downs safely and securely hold tools and safety gear.

Installation Tools & Accessories

Use j hook pliers and j hook sockets to make installation easier. Use the j hook peg board to organize hooks while in workshops. Learning how to execute j hook maneuvers properly ensures wire cable routing is neat and free of tangles.

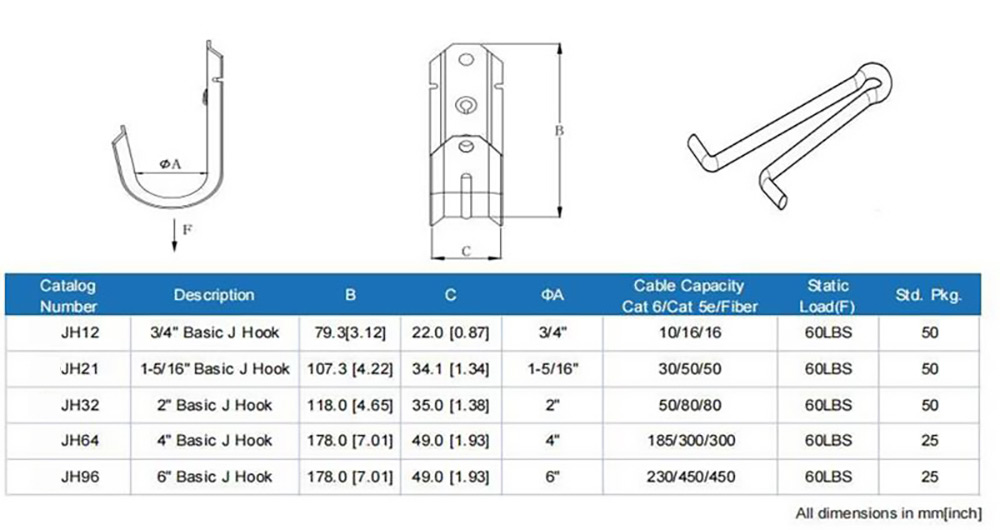

Cable Fill Capacity and Load Limits

Choosing the right size j hook for your project is important. A 4 inch j hook (roughly 100 mm diameter) can support safe loads of 330 Cat5e cables or 140 Cat6a cables. These numbers assume the j hook is filled to 70% capacity. Overfilling a j hook causes cable crushing and loss of signal. An underfilled j hook can cause the j hook to sag. Adhering to fill capacity limits protects your cables and system dependability. Always refer to manufacturer specifications as well as technical standard documents such as TIA-569.

What are Common Mistakes and How Can You Avoid Them?

Some common mistakes can be overloading the j hook, inappropriate spacing leading to sagging or stress, not choosing an adequate material for the application or location, and neglecting to separate cables. These mistakes can lead to j hook failure and damage to wires, even with proper capacity fills. The spacing procedure of cables is more important at a minimum bend radius, especially low voltage and data cables. Consideration should always be made to ensure that outdoor applications have the proper material to avoid corrosion. Separating cables helps avoid cable signal interference and maintain a level of performance.

Where to Purchase and How to Choose the Right J Hooks

Some reliable suppliers include typical retail stores like Lowes, in addition to specialty vendors that have certified J Hooks products. In most applications, a 4 inch j hook is your best bet for a product that can be suitable for multiple cables. Smaller j hooks are typically for light duty cables while larger or specialized j hooks can carry additional strength with an optional installation of j hook screws or wall mounts. Whatever is settled on regarding sizing, a balance between price and quality will be required in order to ensure the cables have guaranteed long term protection which is essential in terms of equipment maintenance.

Conclusion

Overall, J Hooks are a great flexible and cost-effective option for cable clutter and cable management across all industries and wire/cable types. Their relatively simple design allows for bend radius, which protects the cable and increases longevity. From low voltage telecommunications and construction in all environments and even personal organization; J Hooks can adapt to the level of the need, even becoming specialized such as j hook screws, j hook rebar j hook, and luggage j hooks depending on the application. From all these options, J Hooks can provide even more productivity with an easier way to manage your cables, which are safer and cleaner. Truly, a smart choice to eliminate cable clutter!