How Fiber Optic Cleaners Save $10K: $1200/yr ROI Formula & Tool Matrix

Just after midnight, an operational check of a high density optical link at a major metropolitan Optical Network Operations Center failed to connect to the network. The Operations team was immediately deployed to isolate the issue. While investigating the problems, several dry wipe cleaning attempts failed due to static charge holding dust to the connection point before Fiber Optic Cleaners were correctly used. Ultimately, the source of the problem was found to be microscopic dust buildup on the MPO interface, which connects multiple fibers together. Over a period of several months, the added microscopic layer of dust on the MPO connector raised the optical insertion loss to nearly 1.0 decibels, resulting in a complete loss of transmission. The outage lasted over three hours and cost the company tens of thousands of dollars in lost revenue.

It is important to note that fiber link issues are usually caused by the contamination of the connectors, which are particularly more susceptible to becoming contaminated due to dust accumulation or oil on the fiber links when located in dry storage areas where they are fabricated or manufactured. Dust or debris with static charge can scatter light and cause misalignments. The use of generic, synthetic wipes also creates a buildup of static charges resulting in re-accumulation of the contaminants. Each additional time operators attempt to clean the connectors, the cost of inspection, reinsertion, and retesting increases until the contaminants create a measurable signal loss. Cleanliness is frequently viewed as an afterthought when maintaining fiber-based systems; however, it is essential to equipment’s operating reliability and ROI.

The above list is evidence that you don’t need to buy a completely new set of equipment to have a reliable signal. Having process discipline and the right tools leads to having a reliable signal from an initial installation. Using commercial-grade cleaning solutions and products designed for the local environment will assist in preventing re-contamination of the connectors and maintaining accurate connector geometry. Connecting to ESD-safe materials provides a way to dissipate static, while using solvent-balanced fabrics such as microfibre reduces the buildup of oil and dust without damaging the ceramic ferrule surface. When these techniques are utilized properly, loss can be reduced to below 0.15 dB, which helps eliminate slow buildup that dramatically reduces capacity over time.

Why Contamination Quietly Destroys Uptime

Why Contamination Quietly Destroys Uptime

Contamination can exist in a variety of physical forms in different environments. In dry data halls, for example, static electricity causes micro dust to be attracted into the cavities around bulkheads; while in industrial factories, oil vapor from the air captures pieces of metal and grit as it travels. In the case of field installations, items such as lint or pollen can adhere to open connectors within seconds. When an insertion loss reaches above 0.3 dB (high-speed runs) and 0.5 dB (short industrial networks), an alarm will trigger. It is important to note that any replacement of cords or modules will only address the symptom, not the cause of the contamination impact.

A static charge builds up on connector inserts, referred to as ‘ferrules,’ whenever they are wiped dry. The static charge serves as a magnet for dust particles, and every time the insert is reinserted, more particles are forced into the connector. Non-conductive dry wipes simply distribute the dust and do not remove it from the insert. ESD-safe cleaners create a charge that lifts the debris from the insert and also generates a charge that is repelled by the debris, making it easier to clean the insert without damaging the ferrule. Oil residue in a factory presents a much more complicated problem. Alcohol can only dilute the oily residue film and cannot lift a viscous film of oil from the ferrule.

Industrial cleaning kits typically utilize neutral pH solvents and absorbent fibers to completely remove oil residue from the ferrule, returning the connector to a clean optical interface. A field engineer’s race against contamination is speed. Tissue-based wipes shed fibers while precision lint-free cloths do not. Matching the cleaning tool to the environment (dry, oily, windy, or dusty) is key to maintaining stable operation and reducing recurring faults. This means each environment has its own logic for cleaning and therefore should be considered separately to align with the local contamination sources associated with that environment, ultimately resulting in improved uptime, increased SNR, and decreased component failure rates.

What Tools Deliver the Best ROI

What Tools Deliver the Best ROI

For example, in static-dense facilities, ESD-safe precision cleaning kits are designed with conductive polymer tips that neutralize electrical charges and allow access to recessed connectors. By quickly solving that issue and restoring the link margin, time spent troubleshooting is decreased. In an environment with oil mist, a solvent-resistant tool will outlast a cleaner or wipes from the consumer market and will not break down in the presence of solvents. If an engineer works in an open atmosphere (in the field), using a lint-free clicker and rapidly drying solvent can be a very effective method of repeatedly cleaning connections.

The use of ruggedized housings for the tools will also prevent them from breaking down if they are subjected to vibration. Because customers are now aware of these options, they can choose the appropriate cleaner based on their environment, resulting in improved technical and economic performance. This can be seen through fewer outages, quicker restoration times, and a lower frequency of tool replacements, resulting in an accumulation of cost savings over time.

How Clean Connectors Create Measurable ROI

How Clean Connectors Create Measurable ROI

Clean connectors deliver quantifiably improved financial performance. The calculation for ROI is straightforward, being based on patterns for downtime and maintenance. A reasonably sized data center suffers a total of four-fiber outages annually, each one having the potential for creating approximately $3,000 per hour in lost productivity. According to numerous studies and field audits, connector contaminations account for 50%-70% of the incidents, after connector contamination is discovered to be caused by external elements (airborne dust) inside the MPO connector and by residue (dust, debris, and oil) on the ferrule.

Upgrading from traditional cleaning kits to more advanced ESD-safe and oil-resistant cleaning kits (about $1,000 per site/year) will prevent approximately four of the above-mentioned incidents from occurring every year, thus providing roughly $12,000 per year, a more than 10 to 1 return on investment. The same principle holds true and applies to all small facilities.

Also, cleaner connectors have quicker inspection times, less noise, and result in less rework. Durable tools have a lifespan that is 100 times greater than conventional tools and save about 30%-40% on replacement costs. Cross network aggregations have produced an unequivocal relationship between the frequency of cleaning and return-on-investment:

- Low activity venues with fewer than 12 cleanings per month should monitor performance until upgrades can be justified.

- Moderate usage venues that receive between 12 and 35 cleanings per month earn a steady return on investment from only partial implementation of a solution.

- High usage venues that experience 35 or greater cleanings per month experience at least $5,000 of annual savings due to less troubleshooting and decreased downtime.

While cleaning seems to be a low-cost consumable item, it is essential to the continued operation of an asset, acting as a form of ‘insurance’ against downtime. As such, every potential outage avoided equates to either revenue retention or revenue generation. Changing the perspective of cleaning as an expense to that of an operational investment will lead to engineering managers making budgetary decisions that are based on quantitative measures of the economic impact of uptime.

How Static and Oil Films Cause Hidden Failures

How Static and Oil Films Cause Hidden Failures

Static and oil residue are two aspects of the same problem: failure due to improper cleaning methods. When a metal ferrule is cleaned by using a dry cloth, it generates friction which causes static electricity to build up on the surface of the ferrule. This static electricity creates an electrostatic field around it which attracts airborne dust back to the ferrule as soon as the cloth is removed. In addition, airborne mist from oil-based lubricants or coolant used in many industrial processes creates thin, viscous films that attract and hold onto very small quantities of fine dust particles. Both types of contamination significantly degrade signal loss and reflectivity performance. Contaminants are eliminated from both active contacts and inactive connections during cleaning. Using a small amount of properly designed conductive solvent creates an instantaneous pathway for static discharge and positive removal of particulate contaminants from contacts.

After allowing several seconds for sufficient contact with the surface of the component and eliminating static charge, the residue can be wiped away with an ESD-safe fabric, resulting in a neutral surface state. The surface tension of the solvent must be balanced: It will lift oils but should not scratch the polished ceramic surface. Field technicians have reported that frequent use of this method results in significantly lower instances of recontamination and stable levels of insertion loss for a minimum of two to three weeks, as opposed to two to three days. Less frequent intervention, false alarm incidents, and reactively maintained inventory are just some of the examples of ROI improvement where this process has far-reaching benefits.

What to Know Before Choosing a Cleaning Solvent

What to Know Before Choosing a Cleaning Solvent

Solvent Type | Key Strengths | Limitations | Ideal Applications | Evaporation (sec) | Surface Tension (mN/m) |

Fluorinated HFE Blend | Excellent oil removal, mild static relief | Moderate drying speed | Bulkhead static and light grease | 35 | 12 |

Hydrocarbon Precision Fluid | Deep residue removal, high penetration | Slower evaporation | Factory ferrules exposed to oil | 50 | 18 |

Neutral pH Solvent Mix | Gentle on polished surfaces | Weaker on heavy oil | Routine data hall cleaning | 28 | 15 |

The laboratory data shown in these rates are from tests performed at normal levels of relative atmospheric humidity (40%-50%), for a typical Asian hall environment. Because the absolute humidity of the surrounding atmosphere has a direct influence on how quickly the solvent will evaporate, the technician will adjust the dwell time of the solvent as required. Solvents used to reduce the friction on the surface of the ferrule will also extend the ferrule’s working lifespan, as well as avoid the creation of micro-scratches, which could cause the scattering of light.

How to Clean Connectors the Right Way

An ongoing, routine clean will yield consistent, repeatable outcomes. To begin, use a power meter or OTDR to determine baseline signal loss before cleaning, then, using an appropriate solvent, apply a very small amount to the bulkhead cavity to allow the residue to soften for a few seconds. Using a dedicated swab that is inserted at an angle, apply light pressure and remove the swab. Reinsert the swab at a 30–45-degree angle in order to clean out the corner area. After performing this step and verifying there is no loss of signal or increase in insertion loss, check the inspection/power loss of the link and determine if it has returned to within tolerance level.

Across all the facilities utilizing this procedure, more than 90% of the technicians have stated they experienced first pass success rates of over 90%. By taking this approach, predictive maintenance has turned many unplanned link failures into a predictable, repeatable maintenance task over the months. The data from these technicians indicates a significant operational improvement.

Why Oil and Short Tool Life Crush Manufacturing ROI

The factory environment can kill your business in two ways: With oil film buildup on machinery and with the very short lifespan of tool bits. As lubricant mists float in the air and land on connector interfaces, they create an oil film, which is very difficult to remove. Poor cleaning sticks made from the cheapest materials have dried adhesive at the tip that quickly deteriorates after contact with oil, leaving scratches and debris on the connectors. Industrial cleaning kits resistant to solvents are manufactured with fiber tape materials that effectively remove all debris from connector interfaces without losing material and without degrading over time.

Therefore, using these products will allow you to keep clean tool surfaces and extend your tool’s life many times longer than using less effective products. An examination of connector operations at several different locations using microscopes shows that signal loss is greatly reduced after the removal of oil layers. One connector on its own may not produce a great deal of improvement; however, when viewed in the context of an entire production line, the signal loss defines whether the maintenance performed on the machinery is being done in chaos or in an orderly and controlled manner. The stability of the machinery creates additional throughput and improves the life of the components.

Although the savings from this increased level of uptime will not be realized in the company’s financial statements, they will be felt very strongly in terms of the amount of time the machinery remains operational.

What Field Engineers Should Focus On

Wind, dust, and sunlight all affect field technicians, while also limiting their productivity. Airborne lint results from every open-air exposure, and when field technicians utilize standard tissues to clear debris, they may actually worsen the outcome, leaving loose fibers behind. When field technicians use lint-free wipes constructed with continuous filament materials to wipe their connections, they will make a clean connection on the first pass, eliminating the need for rework weeks later. Field technicians also suffer from vibration and mechanical forces that can destroy fragile equipment within factories.

To withstand multiple use cycles without breaking, reinforced cleaning tools should be equipped with a multi-layer housing and internal suspension system. When vibrations create a constantly changing environment, the ability to clean continuously is paramount. Therefore, when the cleaning tool breaks, it not only costs money for replacement, but it creates downtime as well. Therefore, both speed and durability are critical for success in these opposite environments, and the correct cleaning tool will support both of these features.

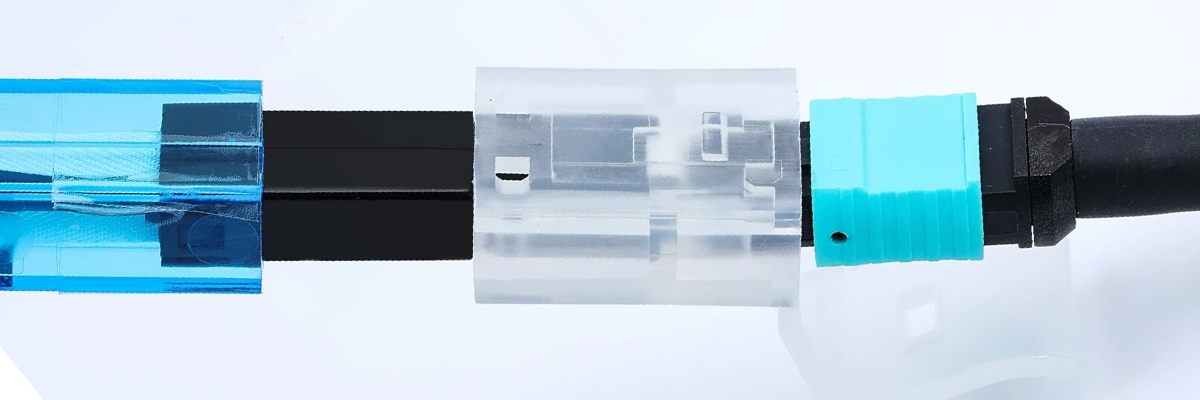

How to Break the MPO Contamination Loop

The use of MPO (multifiber) connectors creates different issues when compared to standard single fiber connectors. A dirty fiber core can reduce performance in all MPOs in the array. Dust tends to migrate in from the edge of the connection to the interior and creates contamination issues with all adjacent fibers. The solution to this issue is to develop a systematic cleaning approach, by first cleaning the MPO adapter and then cleaning the MPO connector, working from the outside to the inside. The cleaning method should include the use of a mild solvent, drag through the solution, and cross-angle inspection after the solution has been wiped off of the fiber to prevent contamination of adjacent fibers.

Visual inspection with a scope or power level readings taken from the MPO connector can be used to determine that all MPO channels have equal brightness levels, which indicates that the same level of cleaning has occurred to each channel. Adopting this systematic approach has consistently resulted in a first pass cleaning success rate of greater than 90%—making this process essential for 5G backhaul and hyperscale deployments, where the MPO density often exceeds 100 ports per rack.

Why a Cleaner Connector Means a Stronger Bottom Line

Why a Cleaner Connector Means a Stronger Bottom Line

By implementing process discipline and alignment with their environmental surroundings, the team of fiber resources can recover much of the hidden value of connected systems. India and outsourcing/industrial support are the two primary methods of delivering fiber. Between both types, there has been substantial evidence that clean, properly maintained endpoints will save a company a minimum of $10,000 each year in lost time due to re-evaluation and unused resources, whether they are data centers, industrial sites, or outside plant operations.

The idea that clean connectors are critical to ensure success is a very simple one. Static-free cleaning products reduce the risk of foreign materials (e.g., dust) adhering to optics, and using a solvent-free clean wipe to remove oil residues on an optic connection point (where fiber connections are made) significantly reduces contamination. Implementing a formalized optic inspection protocol allows for a predictable workflow of between 5 and 15 minutes on non-predictable outages. Thus, in terms of fiber optic systems, there is a direct correlation between clean optics and operational excellence. In terms of finances, the more optic connections that are clean, the greater the potential savings will be.

📚 Reference Sources

- EXFO: Sources of Fiber-Optic Network Issues in the Data Center – Details connector contamination as primary failure cause.

- Connector Supplier: Contaminated Connectors Compromise Fiber Optic Networks – Explains dust, static, and oil impacts on signals.

- DINTEK: Fiber Optic Network Problems: Causes and Fixes – Covers contamination leading to fiber failures.

- IEEE Xplore: Fiber Optic Installation and Maintenance – Shares best practices to reduce downtime.

- MicroCare: Automated Touchless Cleaning for Fiber Optic End Faces – Discusses dust, oil, static removal techniques.

- Chemtronics: Cleaning Study Optimizes Reliability of Fiber Optic Connections – Validates cleaning for bandwidth and ROI.

14-in-1 Fiber Optic Cleaning Tool Kit with 400X Magnifier, MPO Cleaning Pen, and Cleaning Box

- Complete Cleaning Set: This cleaning set features 14 cleaning items, including a 400X magnifier, MPO cleaning pen, cleaning wipes (150 pcs), replacement tips, cotton swabs, air blower, brush, alcohol bottle, and a suitable cleaning box to keep everything organized.

- Sturdy and Portable Case: Sturdy, wear-resistant case that is convenient to fit in your tool kit easily when you are on the go! Case size 26×18×15 cm and weight is 1.31 kg, with a waterproof woven shoulder strap, making it convenient to store and organize.

- Quality Cleaning Tools: Cleaning wipes are lint-free, dust-free, nonwoven, and can be used to wet or dry clean fiber optic endfaces to ensure they are clean before and after cleaning.

- DIY Option: Option to use individually, or in conjunction with different tools, providing customers flexibility in how and what they want to clean fiber optic maintenance related items.

- Accurate Inspection: Having the 400X magnifier allows you to find microscopic dirt and potential damage to fiber endfaces, ensuring excellent quality control.

Why Contamination Quietly Destroys Uptime

Why Contamination Quietly Destroys Uptime What Tools Deliver the Best ROI

What Tools Deliver the Best ROI How Clean Connectors Create Measurable ROI

How Clean Connectors Create Measurable ROI How Static and Oil Films Cause Hidden Failures

How Static and Oil Films Cause Hidden Failures What to Know Before Choosing a Cleaning Solvent

What to Know Before Choosing a Cleaning Solvent Why a Cleaner Connector Means a Stronger Bottom Line

Why a Cleaner Connector Means a Stronger Bottom Line