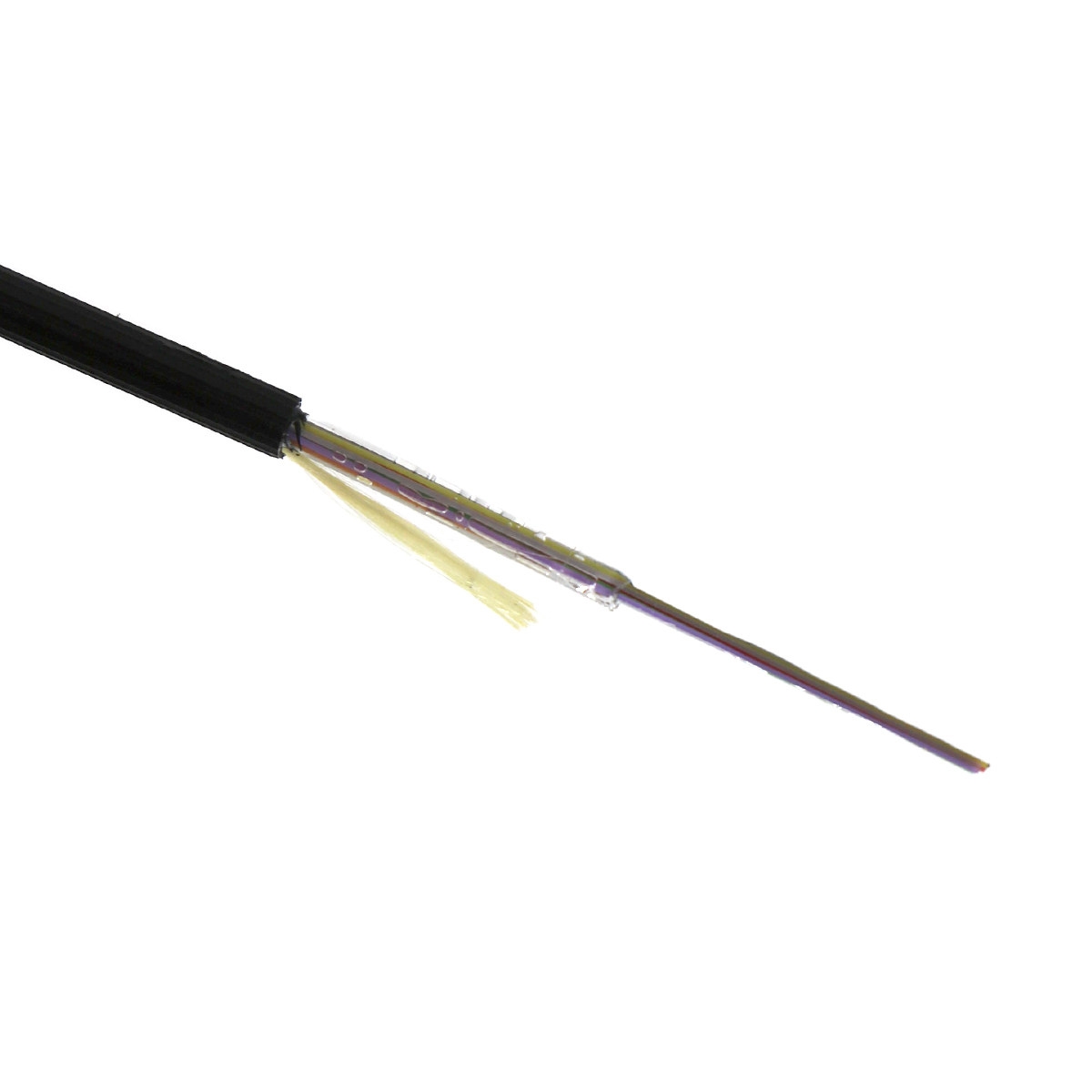

The GCYFXTY Outdoor Air Blown Micro Fiber Cable has an outer diameter of 2.8 mm to 4.0 mm and is produced with a low-friction HDPE sheath (COF≤0.20) and a short-term tensile strength of 300 N; these characteristics contribute to long blowing distances with minimal resistance when deploying through a narrow microduct using compressed air.

Fiber length control within the PBT central tube has been precisely designed to allow sufficient space for all designed fibers to move freely inside the tube when the temperature is changing. As the temperature rises or falls, the fibers will expand or contract freely inside the tube without causing stress, keeping the attenuation values of the fiber stable.

Because all components used in the construction of the GCYFXTY Outdoor Air Blown Micro Fiber Cable are made of non-metallic materials, the cable’s dielectric design eliminates the need for safety grounding and lightning-induced surge protection; therefore, it is perfect for use in roadside and outdoor duct deployments. The jelly-filled tube construction provides a barrier to longitudinal water migration, protecting the fibers while deployed outdoors.

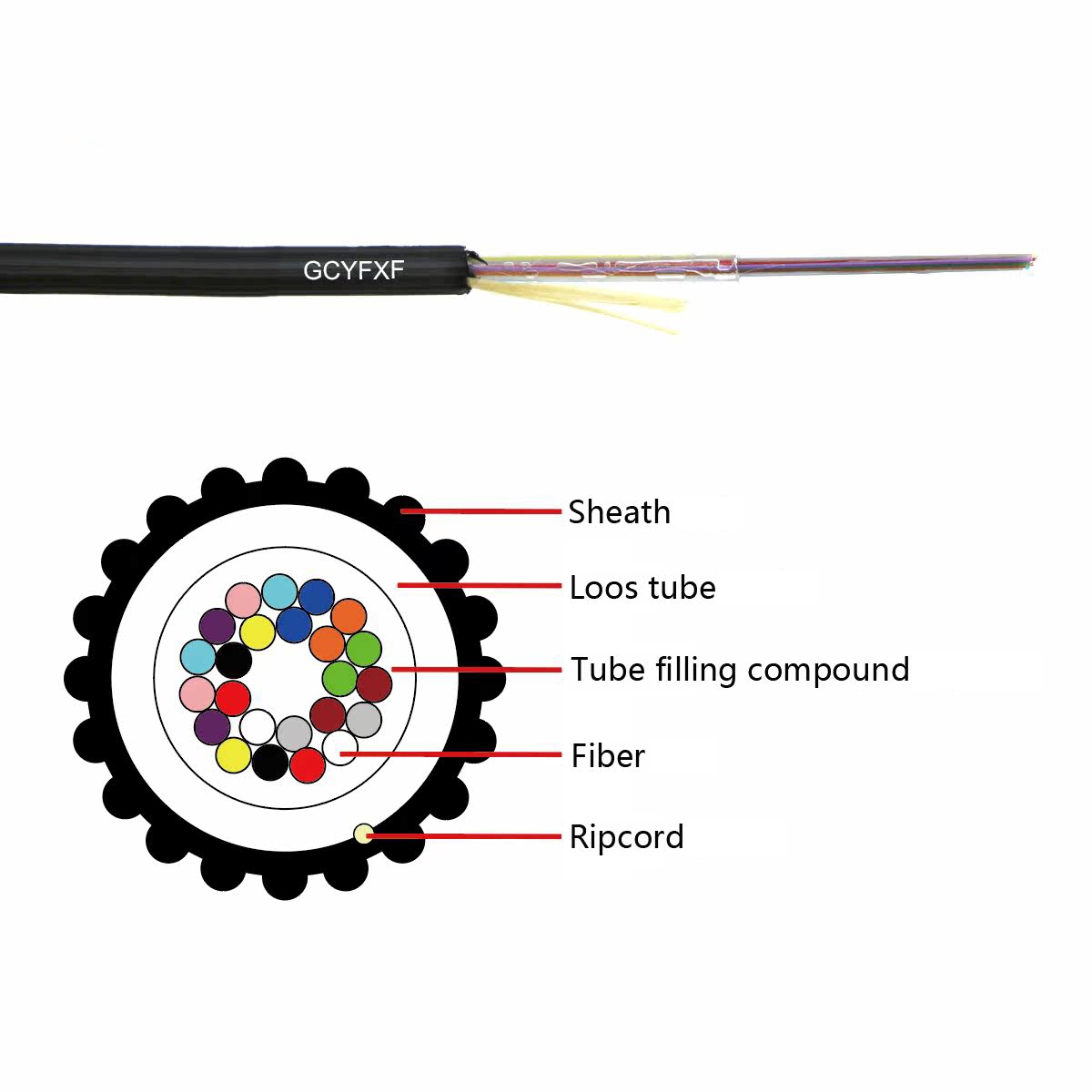

Cable Structure

| Component | Material | Function |

| Optical Fiber | ITU-T G.652D Single-Mode | High-speed, low-attenuation transmission |

| Central Loose Tube | PBT (High Modulus) | Protects fibers from stress and moisture |

| Filling Compound | Jelly-filled Water-blocking | Longitudinal water blocking + fiber cushioning |

| Strengthening Element | Aramid Yarn | 300N short-term tensile protection |

| Outer Sheath | Low-Friction HDPE (COF ≤ 0.20) | Enables long-distance air blowing |

| Ripcord | Polyester | Easy sheath removal |

Mechanical & Environmental Performance

The GCYFXTY withstands installation stresses and outdoor conditions while maintaining optical stability.

| Parameter | Typical Value | Remarks |

| Cable Diameter | 2.8 – 4.0 mm | Depends on core count (2-24 cores) |

| Cable Weight | Nominal 5 – 13 kg/km (Subject to core count and diameter) | Lightweight for easy handling |

| Tensile Strength | Short-term: 300 N / Long-term: 100 N | Aramid yarn protection |

| Crush Resistance | Short-term: 1000 N/10cm / Long-term: 300 N/10cm | Resists duct deformation |

| Minimum Bending Radius | Dynamic: 20× / Static: 10× Cable Ø | Tight duct compatible |

| Operating Temperature | -20°C to +70°C | Excess length prevents temp-induced loss |

| Installation Temperature | -10°C to +60°C | Air-blowing optimized |

| UV Resistance | Excellent | HDPE jacket protection |

| Water Blocking | Jelly-filled tube | Longitudinal water resistance |

Optical Characteristics

| Parameter | Specification (G.652D Fiber) | Remarks |

| Attenuation @1310 nm | ≤ 0.35 dB/km | Access network optimized |

| Attenuation @1550 nm | ≤ 0.21 dB/km | Long-haul capable |

| Chromatic Dispersion | ≤ 18 ps/nm·km @1550 nm | High-speed service ready |

| Mode Field Diameter | 9.2 ± 0.4 µm @1310 nm | Connector compatible |

| Proof Stress | 1% | Manufacturing standard |

Application Scenarios

- High-density installation of ducted FTTx/FTTH fibre.

- Modular underground fibre installations in data centres.

- Long runs of ducted fibre backbone on metro and campus networks.

- Expanding broadband and CATV networks.

- Security and industrial monitoring applications.

The small diameter of the fibre, compared to other products, combined with a low coefficient of friction, allows for easier blowing out of cables from compatible microducts and replacing them with higher-capacity versions without having to dig up the ground.

Reliability & Installation Advantages

The low friction (≤0.20 coefficient of friction) of the HDPE material results in 30–50% less blowing resistance compared with standard jackets and provides fibre installers with the ability to blow fibre up to 1000+ meters in straight runs with a 300 N pull test rating.

Lightning protection from non-metallic construction prevents ground faults that typically occur in roadside ducts. The jelly-filled tube creates a barrier between any water and the fibre, even if the outer sheath is damaged.

Packaging & Delivery

Supplied on reels using shock-resistant packaging and internal cushioning material to eliminate the potential for fibre movement within the packaging during transportation. Wooden and plastic reels are made to order for each fibre length. Each reel has individual batch traceability and compliance markings.

GCYFXTY provides 1000 N crush resistance at 10 cm, 300 N tensile strength, and a coefficient of friction≤0.20, all in a compact 2.8–4.0 mm package. The excess fibre length and jelly-filled PBT tube provide stable transmission from -20°C to +70°C. The non-metallic lightning protection and the ability to blow out and upgrade the system make it ideal for FTTx densification and metro backbone applications where duct space and reliability are paramount.

Reviews

Clear filtersThere are no reviews yet.