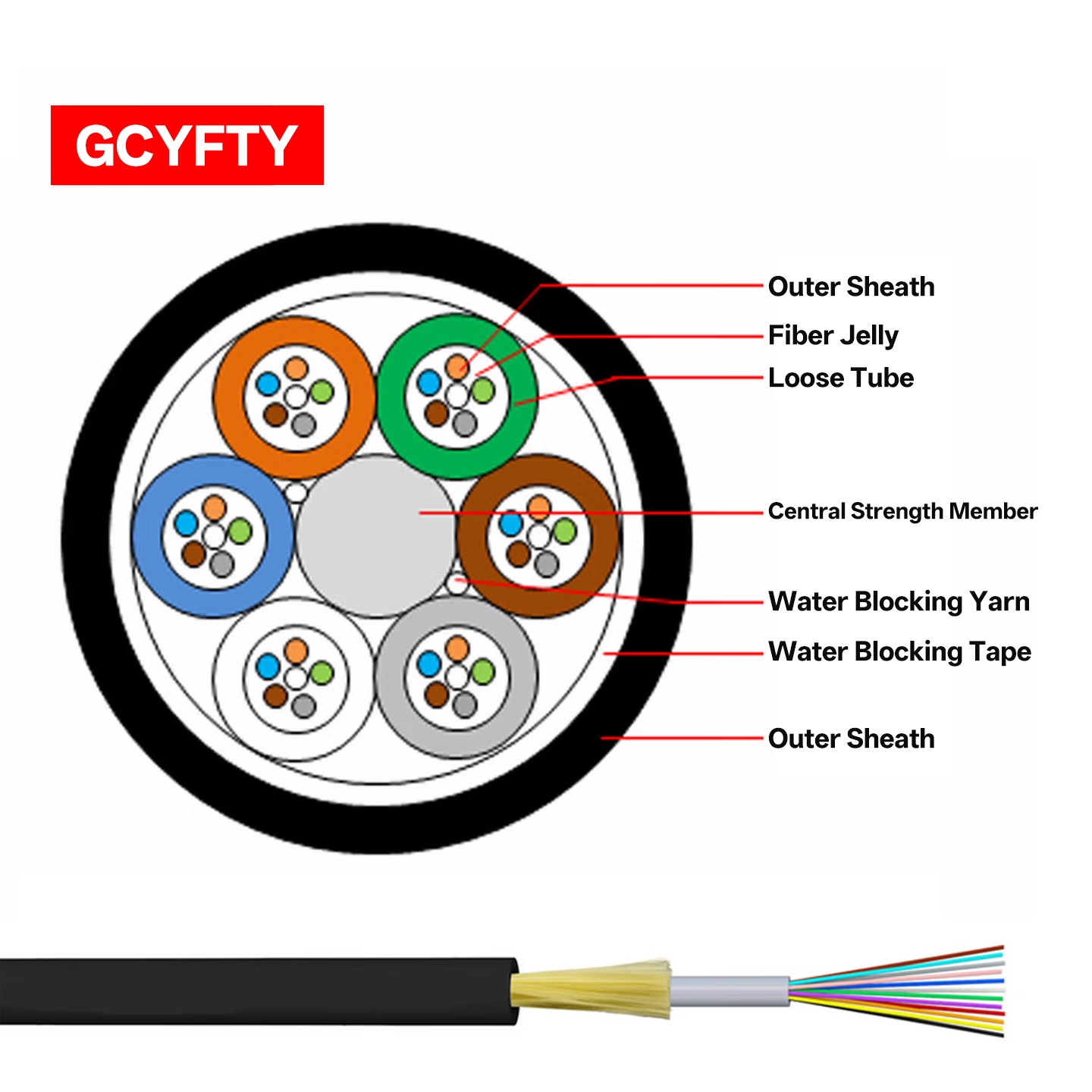

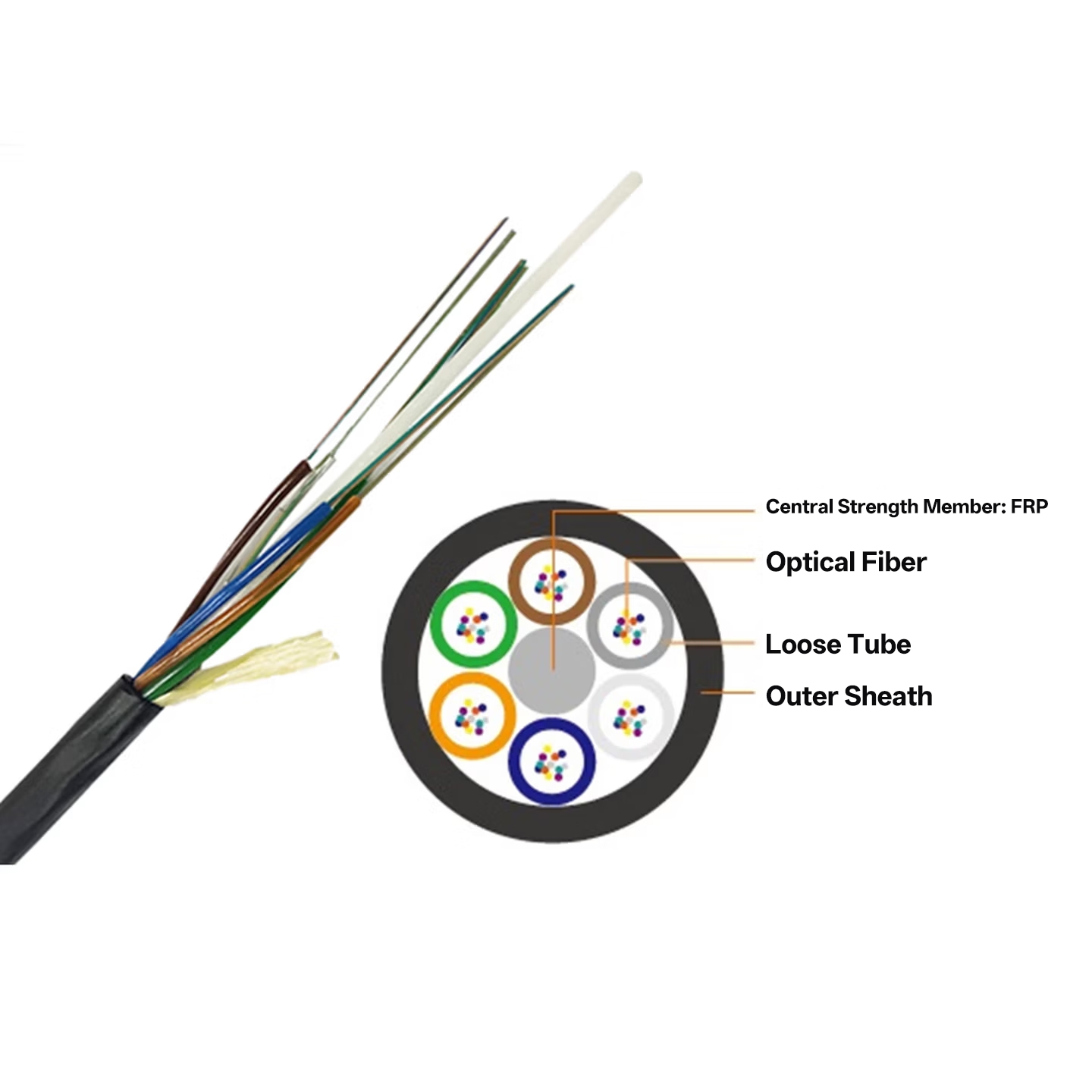

The GCYFTY Outdoor Air Blown Micro Fiber Optic Cable features a specialized design known as stranded loose tube. The cable structure consists of fibers encased within a number of gel-filled tubes that surround a central strength member made from FRP. Additionally, water-blocking yarns and tapes are applied outside the loose tubes to fill any gaps that could allow water to enter the cable and damage the fibers. The outer jacket of the cable is made of a tough, durable polyethylene (HDPE) material that protects the entire assembly from harm.

The design is highly suitable for installation in ducts, as air-blowing installs the cable much faster and easier than traditional methods. For instance, using this type of cable allows installation crews to blow very long lengths of cable into microducts without having to make any pulls or splices during the process. The cable has the capacity to carry 4 to 144 fibers, all of the G652 single-mode type.

Now that we have discussed the details of how the cable is built, let us turn our attention to the actual mechanical properties of this cable when it is used in the field. The GCYFTY cable can withstand both short-term and long-term pulls of up to 600N (short-term) and 200N (long-term) respectively. Crush resistance of up to 400N can be applied short-term and 150N on a continuous basis. The impact tests performed on this cable included a drop test, where a test weight of 450g was dropped from a height of 1 meter onto the jacketed end of the cable with a hammer that had a 12.5mm radius, obtained five times (Tested according to IEC 60794-1-21 Method E4).

At no time did any fiber show attenuation change or outer jacket rupture due to these impact tests, and the cable was able to withstand five consecutive blows (a drop is equivalent to one blow). The tensile properties of this cable make it ideal for duct blowing applications, as air pushes the cable around turns or bends. The non-metallic FRP member provides high tensile strength and excellent anti-buckling properties, ensuring smooth pushing during the air-blowing process. Optional aramid yarns may be included in the production of additional cables to enhance the cable’s tensile capabilities. The HDPE material remains flexible at temperatures as low as -40°C and remains stable at temperatures of 70°C and higher, which has been confirmed through ongoing flex testing conducted pursuant to IEC 60794 standards, as no embrittlement or softening occurred during the applicable tests.

Mechanical Characteristics

| Property | Short-term | Long-term | Test Notes |

| Tensile Strength (N) | 600 | 200 | Per 100mm section |

| Crush Resistance (N) | 400 | 150 | No fiber damage |

| Impact Resistance | 450g × 1m, 12.5mm radius, 5 hits | N/A | No attenuation or cracks |

| Operating Temperature (°C) | N/A | -40 to +70 | Full range |

The factory data provided these values. Short-term values measure installation stress during blow loading, while long-term values indicate daily dependence on a consistent tension release rate.

Structure & Environmental Characteristics

| Component | Material/Details | Function |

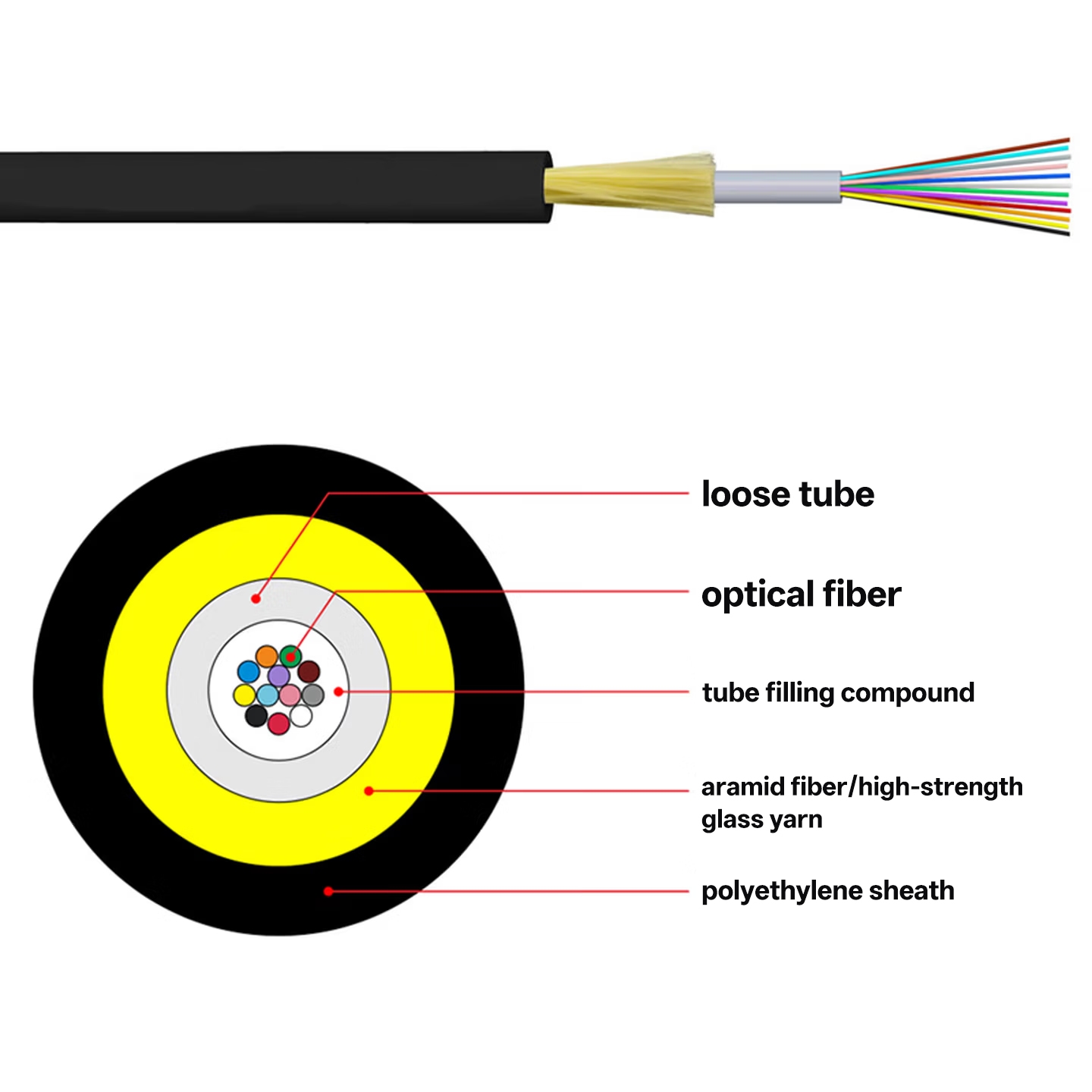

| Optical Fiber | G652D SM, 9/125μm | Signal transmission; low loss: 0.22dB/km@1550nm, 0.36dB/km@1310nm |

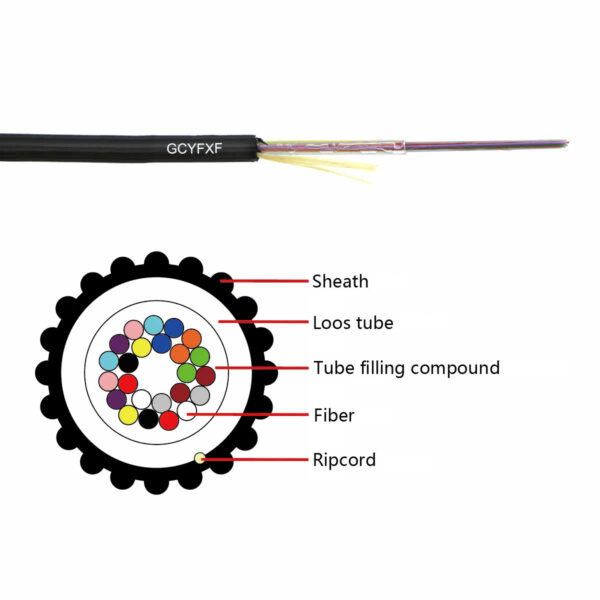

| Loose Tube | High-modulus plastic, gel-filled | Protects fibers; hydrolysis-resistant |

| Central Member | FRP (non-metallic) | Anti-buckling; tensile strength; lightweight |

| Water Blocking | Yarns, tapes, compound | Prevents moisture ingress; half-dry design |

| Strength Layers | Aramid/glass yarn | Tear resistance |

| Outer Jacket | HDPE, black | 30-year life; corrosion/UV-resistant; fresh granules for no odor, durability |

| Core Count | 4–144 | Customizable |

| Cable Diameter | 5.8–8.6mm (depending on fiber count) | Micro design for 14/12mm or 16/12mm microducts |

Core Count and Diameter Reference Table

| Fiber Count | Typical Outer Diameter (mm) | Recommended Microduct |

| 4–24 cores | 5.8 | 10/8 or 12/10 mm |

| 48–72 cores | 7.0 | 14/12 mm |

| 96–144 cores | 8.6 | 16/12 mm |

Environmentally friendly, HDPE jacket made of new granules. Factory testing of the HDPE jacket shows purity through accelerated aging per IEC specs, indicating that HDPE jackets are corrosion-resistant and have an ultra-smooth installation surface that minimizes drag. The HDPE jacket will not cause pollution, can withstand heat, and can last much longer than typical conduits. All test results comply with international tests. Microduct systems install outside, and cables are installed with air-blowing into microducts that are very tight. Minimal shrinkback of the HDPE jacket ensures the stability of the fiber-to-cable length ratio after installation.

The performance of GCYFTY cables stands out in the network. The cables support FTTH drops and backbones/metro links. They can be blown in 1km or 2500m in a much shorter time than the 3–5 days it would take if pulled into a duct. They will maintain their circular configuration when they are bent at an angle due to the cable structure and jacket strength, rather than the fibers themselves. The number of cores used is directly related to the performance of the cable and will, therefore, follow G652D performance criteria.

Customization of lengths will accommodate lengths such as 1km or 3km by using reels. The packaging of the cable is designed to protect it during transportation. Even cables under 1000m should be wound on small reels rather than packed in bags to prevent excessive bending. When ordering reels longer than 1000m, a wooden drum is used to prevent the contents from shifting during shipping. The fillers absorb impact from shipping and handling.

Unless otherwise stated, at the factory, all items will be tested: at the mid-point of the manufacturing process with IEC 60794 protocols, and once completed, the manufacturer will check the cables for attenuation and continuity. The factory will send with each reel a report of the tests performed on the cable. When ordering cables, please include the core count and length to affect the pricing. The materials used in the making of the cables determine the final price quote. Please contact sales for custom models.

In summary, GCYFTY offers the most efficient duct runs available. Their cables are small but provide a lot of capacity due to their mechanics, and their mechanics are specifically designed for installation in very harsh conditions. Water-blocks work; therefore, the cables will not give out and will last 30 years. The installation is quick and clean.

Reviews

Clear filtersThere are no reviews yet.