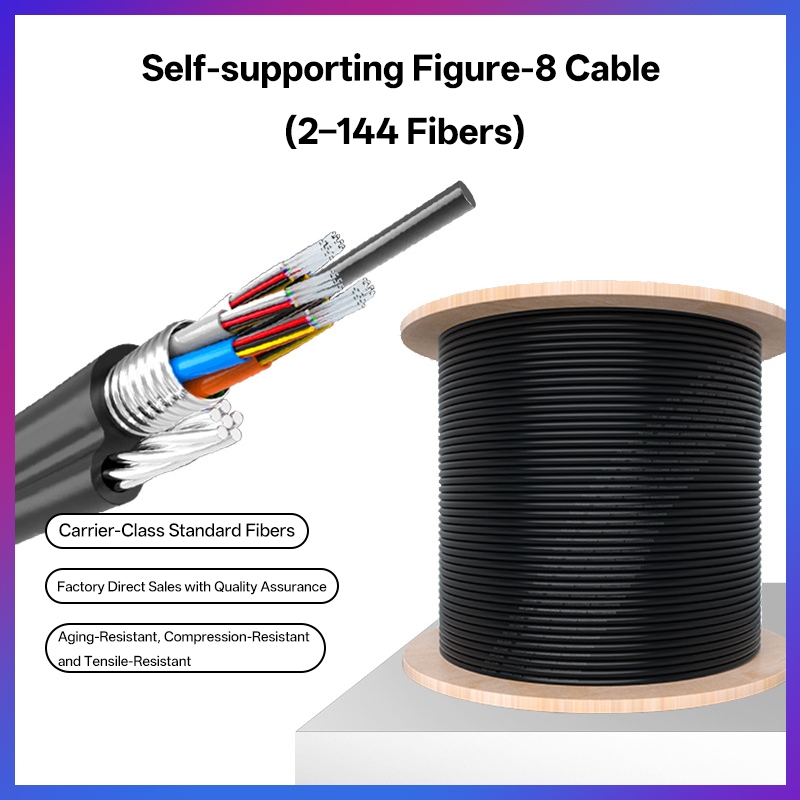

The Figure 8 Fiber Optic Cable GYTC8S 9/125μm G652D Singlemode, Customizable 4–144 Core Outdoor Aerial Cable has been designed to work well in overhead configurations for quick installation by crews as it contains a steel strand as part of the self-supporting 8 shape. Therefore, the fiber optic cables can be affixed to pre-existing utility poles without requiring the use of any additional mounting hardware. The G652D singlemode fibers that are housed in loose tube construction provide a low-loss path for signals.

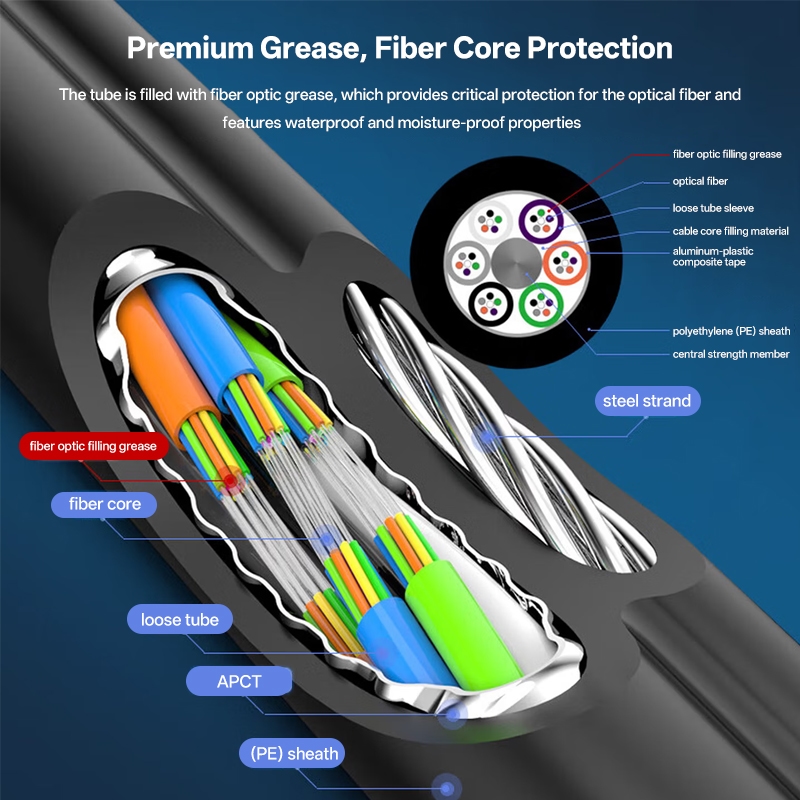

The fibers housed within PBT loose tubes are protected with water-blocking grease, which prevents moisture from affecting the integrity of the fibers. The loose tubes are assembled around a central steel strength member. The spaces between the tubes are filled with additional grease. An Aluminum Polyethylene Laminate (APL) tape protects the core from moisture. The black polyethylene outer jacket covers the entire assembly. A steel strand runs longitudinally down the length of the assembly to form the figure-eight shape, and the phosphated steel in the center provides additional strength to resist tensile forces. The thixotropic properties of the water-blocking grease also help to maintain its hydrophobic qualities regardless of movement. The maximum attenuation is less than or equal to 0.34 dB/km for 1310nm and less than or equal to 0.20 dB/km for 1550nm fiber frequency.

Structure & Environmental Characteristics

| Component | Material | Details |

| Loose Tube | PBT | High modulus, hydrolysis resistant |

| Central Strength | Phosphated Steel Wire | Tension support |

| Peripheral Strength | Steel Strand | Self-support for aerial |

| Wrapping | Aluminum Polyethylene Laminate (APL) | Moisture barrier |

| Sheath | PE / Black | UV-resistant |

| Operating Temperature | -40°C to +70°C | Storage and install same |

| Bending Radius | Static: 12.5× cable dia. | Dynamic: 25× cable dia. |

| Lifespan | Over 30 years | Proper aerial use |

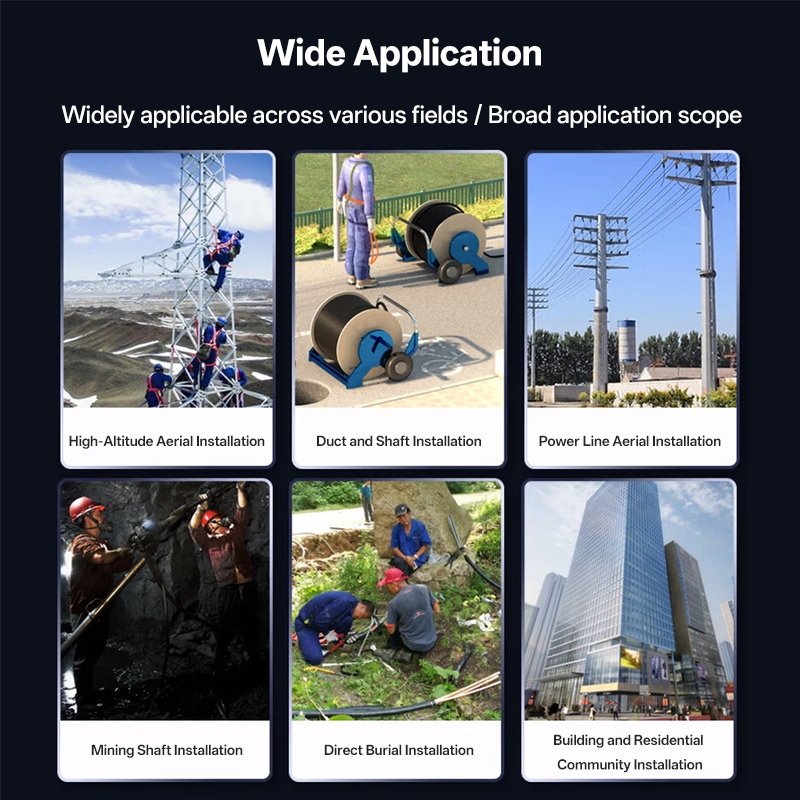

This design is most appropriate for aerial lines and ducts. It can be mounted between two poles or routed through a conduit. The UV stabilizer in polyethylene protects from sunlight damage, while the gel-filled grease and APL (Aluminum-Polyethylene Laminate) provide protection against moisture entering through rain or dew. The moisture barrier of the APL ensures that the cable operates consistently throughout its length when installed in wet underground ducts in humid areas. For example, these cables may be strung between utility poles for overhead applications. While wind may pull on this type of cable, steel will keep everything in place.

For overhead applications, the cable’s mechanical components perform extremely well. The APL and PBT tubes prevent side loading pressure from the clamps from crushing the cable. Steel strands bear the greatest tension when suspending this type of cable. Cables with high-quality cores will have minimal splice losses. Tests using optical time-domain reflectometers (OTDRs) have demonstrated that all fibers in the same cable experience consistent and uniform attenuation levels.

Mechanical Characteristics

| Fiber Count | Dimensions (mm) | Weight (kg/km) | Tensile (Short/Long, N) | Crush (Short/Long, N/100mm) |

| 4 | 9.0×17.0 | 218 | 6000/3000 | 3000/1000 |

| 6 | 9.0×17.0 | 218 | 6000/3000 | 3000/1000 |

| 8 | 9.0×17.0 | 218 | 6000/3000 | 3000/1000 |

| 12 | 9.0×17.0 | 218 | 6000/3000 | 3000/1000 |

| 24 | 9.0×17.0 | 218 | 6000/3000 | 3000/1000 |

| 36 | 10.0×18.0 | 220 | 6000/3000 | 3000/1000 |

| 48 | 10.5×18.5 | 230 | 6000/3000 | 3000/1000 |

| 72 | 11.5×19.5 | 240 | 6000/3000 | 3000/1000 |

| 96 | 11.5×20.5 | 280 | 6000/3000 | 3000/1000 |

| 144 | 13.5×21.3 | 350 | 6000/3000 | 3000/1000 |

Tensile Strength Value Classification: as with applications that require short-term tensile strength for pulls such as installation and long-term tensile strength for daily load requirements; Peak resistance force is higher in the short term with crushing, whereas ongoing pressure force is higher over the long term. Dimension and Weight Trends: Industry standards as defined by IEC 60794-1-21/22.

Ease of Installation and Use: Use with pole clips on the strand, spanning multiple gaps between poles, installs easily, and APL seals around and creates a seal against moisture entering the duct. Drum sizes range from 2000m and 4000m as standard but can be customized. Smooth splicing of fiber is achievable due to the precision of the fiber geometry, which reduces losses. For speed, identify fiber by color code.

Industry Compliance: Covered by ITU-T G652D and RoHS compliant. Standard 250μm color-coated fibers. The fiber is filled with grease to eliminate air pockets and prevent water from forming any paths through the fiber when installed. In practice, this cable performs without failure on rural and suburban routes. The steel supports have been tested through all of the storms and continue to function. The crews are able to finish their jobs at a faster rate versus non-self-supporting types.

The technicians have reported clean OTDR traces on this cable with no weak points detected. The PE cable remains flexible when cold, and the heat does not soften it. Over the time period of 30+ years, the signals can withstand the rigors and hold strong. For use in the telecommunications industry, such as telecommunication towers and electrical power grid applications, this cable performs exceptionally well. The specifications range from 004 cores to 144 cores. Specify drum size. Have you met all aerial installation requirements?

Industry Compliance: Fully compliant with all IEC 60794-1, TIA/EIA 568-B.3, and Telcordia GR-20 industry compliance standards.

Reviews

Clear filtersThere are no reviews yet.