Fiber Optic Connectors

Fiber Optic Connectors: Types, Selection, Installation & Maintenance

Fiber optic connectors are critical components of high-speed networks, which function to securely and dependably connect fiber optic cables. They provide high-speed data transfer with minimal signal degradation, which is vital in large data centers, 5G networks, smart cities and similar environments. Using the proper connector type, installing it correctly, and maintaining it will all directly impact work and uptime for an organization. Understanding the types of fiber optic connectors and how they should be implemented will represent the best way to engage network operations in various environments.

Showing all 7 results

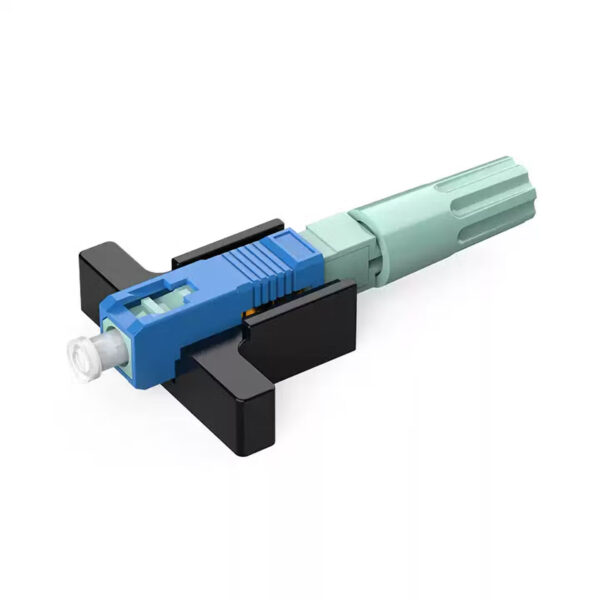

3L Nut Type SC APC/UPC Quick Connector for FTTH Drop Cable

Original price was: $6.00.$0.80Current price is: $0.80.ESC250D SC-APC/SC-UPC Fiber Optic Fast/Quick Connector

Original price was: $6.00.$0.50Current price is: $0.50.

Fiber Optic Mechanical Splice 250µm/900µm – Wireless LAN, Bluetooth, Wired LAN, IP Networks

Price range: $0.65 through $0.99

FTTH SC/APC Fiber Optic Fast Connector, 10 Pcs/Blister Box, OEM Available

Price range: $0.48 through $0.79SC APC/UPC Gland Type Fast Connector for FTTH Drop Cable

Original price was: $5.00.$0.39Current price is: $0.39.

SC/APC Fiber Fast Connector for Single-Mode Fiber Cable

Price range: $0.45 through $0.60

SC/UPC Fiber Optic Fast Connector, Field Assembly Cold Connector for Single-Mode Telecom & CATV Networks

Price range: $0.49 through $0.86What Is a Fiber Optic Connector? Basic Concepts and Key Components

Definition and Core Function of Fiber Optic Connectors

A fiber optic connector is a tool that connects two fiber optic cables end-to-end for the purpose of transmitting light directly between them, as if they were one long, continuous cable. You can think of the connector as a precision adapter, designed to ensure that optical signals are robust and not harmed on their way through the connector. In practical terms, the connector allows high-speed, high-bandwidth data to travel, while signal loss or distortion, due to passing through the connector, is minimized. If we did not have reliable connectors, we would have interruptions (the possibility of many end-users having degraded signals) in telecommunications, data centers, broadband networks, etc. These connecting devices are referred to as fiber optic connectors, and both terms emphasize the core function in optical communications.

Key Components of a Connector: Ferrule, Coupling Mechanism, Housing

The ferrule is the crux of every connector, generally made of either ceramic or metal, as it precisely aligns the delicate fibers for seamless light transfer. Common ferrule diameters consist of 1.25mm or 2.5mm, and these can be important for compatibility across cable types.

Each connector employs some coupling mechanism to secure the connection. The coupling mechanism may be as simple as push-pull latches, threaded screws for stability, or a bayonet twist that locks the connector into place with a simple twist. Regardless of the design, coupling mechanisms retain strength against vibration and mechanical wear.

Each of these parts is enclosed in a housing, which protects against dust, moisture, and physical damage. Housing designs can vary, modifying how well a connector can perform in environments ranging from controlled, indoor settings to rough outdoor installations. Collectively, these components are responsible for a fiber's performance across all types of fiber optic connectors.

Why Quality Matters: Performance Factors

There are two primary indicators for evaluating connector quality in communications: insertion loss and return loss. Insertion loss is a measure of how much less signal power is present across the connection, with lower values representing a lower loss of data. Return loss measures how much light is reflected back toward the source; a higher return loss represents an even cleaner transmission.

Robustness is very important, especially in hazardous or industrial sites, where connectors could be subjected to the elements. In addition, selecting a connector made for single-mode or multimode cables is very important.

Fast connectors have come onto the market to accommodate quick installations without the use of tools and to maintain the integrity of transmission quality in newly forming communication networks.

Emerging Influences – 5G and 400G Networks

New technologies like 5G and 400G are creating more challenges for connectors, particularly in demanding mechanical tolerances, low insertion loss, and environmental robustness. As higher-performance networks emerge, data centers and developing smart city infrastructure will expect fiber optic connectors to meet these demands. The fiber optic industry continues to innovate and advance in each of these challenges.

Overview of Major Fiber Optic Connector Types: SC, LC, ST, FC, MPO, MTP, MTRJ, MU

Common Connector Types

Fiber optic connections are available in different shapes based on your requirements in your network. The SC connector is a push-pull style and is an industry favorite for applications within telecom and data centers because of its reliability. The LC is a smaller connector with a latch lock for high-density environments.

The ST connector has a bayonet twist-lock and is popular in both legacy systems and industrial environments. The FC is used with threaded coupling of the connector for security of the connection, especially in precision optical devices.

The multi-fiber connectors such as MPO and MTP types combine many fibers into one connector for data center applications where there is a lot of data transmitted at once. The MTRJ connector typically operates in duplex and has a compact design, and the MU is also popular in the telecom industry because it operates in ultra-high densities.

Each connector serves a different purpose in different environments based on the technical specifications.

Characteristics and Use Cases

The primary differences between connector types are ferrule diameter, coupling style, and fiber compatibility. SC, FC, and ST connector types are fitted with a 2.5mm ferrule and can work with either single-mode or multimode fibers. Each of the connector types is secured by whichever coupling style is employed, whether that be snap-in, threaded, or bayonet, making them a secure connector choice for both indoor and outdoor applications.

The LC connector type is fitted with a smaller 1.25mm ferrule. The overall size of the LC connector provides higher port density within smaller footprint data centers. The latch promotes easy connection in instances with cycling connections, as in Point of Connection (PoC) equipment facilities.

MPO and MTP (such as MTP Elite and MTP-LC) connectors allow up to 12 to 24 fibers in small modules to meet high fiber count demand throughout technology use in rack-scale and cloud networks and other scalable enterprises.

The MTRJ and MU connector types are specified for applications requiring duplex or ultra-dense fiber connector configurations. MTRJ and MU fiber connectors have improved handling and durability for use in run-and-change networking applications.

Connector Types Comparison Chart

| Connector Type | Ferrule Size | Coupling Method | Typical Applications | Insertion Loss (dB) | Return Loss (dB) | Advantages | Drawbacks |

| SC | 2.5mm | Push-pull | Telecom, Data Centers | 0.2 – 0.5 | 40+ | Reliable, easy to install | Larger physical size |

| LC | 1.25mm | Latch | High-density Data Centers | 0.1 – 0.3 | 40+ | Compact, high port density | Fragile latch mechanism |

| ST | 2.5mm | Bayonet twist-lock | Industrial, Legacy Networks | 0.2 – 0.5 | 35+ | Rugged, durable | Bulkier, outdated design |

| FC | 2.5mm | Threaded screw | Precision Optical Equip. | 0.1 – 0.3 | 40+ | Stable, low reflection | Slower connect/disconnect |

| MPO / MTP | Multi-fiber | Push-pull | High-density Data Centers | 0.35 – 0.75 | 20+ | Multi-fiber, space-saving | Complex polarity management |

| MTRJ | 1.25mm Duplex | Push-pull | Duplex Systems | 0.3 – 0.5 | 40+ | Compact duplex, easy handle | Less commonly used |

| MU | 1.25mm | Latch | Telecom, High Density | 0.2 – 0.5 | 40+ | Ultra-compact, very dense | Requires precise handling |

Trends in Miniaturization and High-Density Solutions

The trend in connector sizes has decreased from larger SC and FC configurations to smaller LC and MTRJ, allowing for increased port density in constrained data center racks. This has also coincided with bandwidth demands increasing.

Multi-fiber connectors such as MPO and MTP are enabling numerous fiber connections to be made into fewer connectors and will assist in the scalable build-out of networks in cloud and telecommunications infrastructures.

Other advancements have focused on making optical fiber connectors as simple as possible while maintaining low insertion and return losses, all while utilizing higher densities of fiber.

How to Choose the Right Fiber Optic Connector Read Fiber Connector Types Guide

Common Issues & Maintenance Tips for Fiber Optic Connectors

How to Prevent Installation Errors

Misalignment in the ferrule and poor polishing may lead to signal loss. Optimum polishing and ferrule alignment can prevent both of these problems. Apply consistent and even force when physically mating two connectors, thereby protecting internal components.

Fast connectors are quick to install. Be sure to check for compatibility—even with mechanical connectors, signal loss can occur from a loose or non-compatible connector. Clean all connectors before mating and do not mate a damaged connector.

Cleaning Fiber Optic Connectors

The integrity of optical signals can degrade due to dust and oils on the connector. Use isopropyl alcohol or fiber cleaners with lint-free wipes to remove all contaminants. Inspect all connectors under the microscope prior to cleaning, gently wipe the contaminated connector, and allow it to dry. Make sure the connector is completely dry before connection to avoid contaminating the next connector. Remove all dust/lint using the lint-free wipe or fiber cleaner and thoroughly dry.

Never use an abrasive cloth or harsh chemicals that can damage the connector. Contamination from dust or oils can also be avoided with regular cleanings to mitigate issues later.

Troubleshooting Signal Loss

Loss of signal at the transmission level can be caused by dust or oil contamination, physical damage to the connector or fiber, or excessive bends to the cable or fiber. Visually inspect all connectors in the network for small chips or cracks, and also observe that the connectors maintain their proper bend radius to avoid signal loss in the transmission process.

To isolate where the loss is occurring within a network, optical power meters or OTDR tools can be used. It is advisable to use a testing checklist to ensure everything that could affect a loss of signal is either clean, undamaged, or appropriately connected. A checklist should always include inspection of all connectors for cleanliness, damage or cracks, compatibility after previously collecting data to ensure the connectors match with the signal, and proper cable routing.

Best Practices for Maintenance

Regular use of fiber scopes will help to identify potential contaminations. Keep connected or unused connectors protected with caps, and safely store connectors in dust-tight cases if the fibers and connector are not in use, while avoiding mechanical or moisture stress. Label connections and test equipment to avoid accidental connection errors.

Regular cleaning, inspections, and testing will help to prolong the useful life of the connectors and the reliability of the network.

Conclusion

Fiber optic connectors offer both stable communication and efficient operation; however, choosing the correct fiber optic connector requires an understanding of application needs, relevant key performance indicators (KPIs) like insertion and return loss, and maintenance requirements.

There are many different types of fiber optic connectors, ranging from low-profile fiber optic LC connectors and quickly connectorized SC APC SM fast connectors to rugged fiber optic ST and fiber optic FC connectors. Maintaining the cleanliness of a fiber optic connector, and cleaning fiber optic connectors consistently, is essential to keeping fiber optic connectors in use and positively affects performance and longevity.

Data centers benefit from MTP fiber optic connectors because they can handle high-density configurations. In more demanding areas (like industry), durability and reliability under harsh conditions are necessary.

To receive more customized recommendations and actionable tools on fiber optic connectors, download a supply checklist or consult the experts or professionals. That way, you can be more confident that your fiber optic connector supply is resilient and efficient.