Fiber Optic Cleaner Sticklers Clicker: From 500 to 750 Clicks — How Rotation Protocols Save $500 a Year

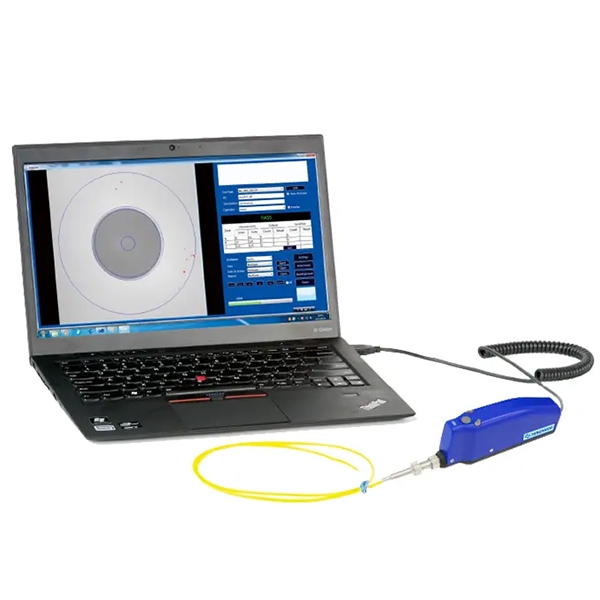

Small details make all the difference between smooth-running production lines and constantly interrupted ones in modern manufacturing. Those small details include different types of fixed-length cleaning “clickers” used to maintain the cleanliness of fiber optic connectors, which are designed to last for years. However, when these devices fail, testing ceases; workers sit idle, and production costs are lost without anyone realizing it. As a result of the generic cleaning clicker’s frequent jamming, electronics maintenance technicians at a multinational company in Southeast Asia have noticed a recurring trend.

Every 10 days, the generic cleaning clicker jams, causing the technician working on the fiber to stop working, change cassettes, and re-calibrate his or her tester. Although a single jam in the fiber may only cause a 20-minute delay, when multiplied across 20 production lines with dozens of technicians, the problem results in significant and repeated losses in output for the month.

The factory implemented a structured maintenance procedure using Fiber Optic Cleaner Sticklers clickers, a type of industrial-quality product. By utilizing regular inspection, tape replacement, and cross-station movement, and implementing a rotation procedure, there has been a dramatic increase in the device’s lifespan from an average of 500 cleanings per cassette to more than 700. Over time, this increase of 40% in the device’s longevity equated to $500 in savings per line annually, simply due to the fact that the employees paid more attention to the devices in a structured manner rather than through the introduction of brand new technology.

Clicker Wear Diagnostic Framework

Clicker Wear Diagnostic Framework

To create an effective maintenance program, the first step is to determine when a specific tool has reached its end-of-life. Engineers identified a simple way to evaluate the “wearing out” process on tools (cassettes) before it caused failure. Technicians performed a quick visual inspection (check) of each cassette once per week for a smooth click, color change, and tape tension.

Approximately 400 use cycles later, a small amount of resistance will begin to appear due to wear of the cassette material. If this small amount of resistance is ignored, then a complete failure of the cassette will occur within a few days. If the resistance is identified at the early stages, a rotation will occur—changing the position of the clicker to a lower duty cycle, logging it in for use, and continuing the tool’s use cycle. The entire process requires no additional equipment but requires consistency.

Within two months of data collection, managers began to witness patterns emerge from the data collected. Cassettes that are located near oily print stations or open air vent locations had a faster degradation rate. Cassettes that were located in dry test rooms had a longer degradation life. Recording and comparing tooling use every week has become the normal routine of the manufacturing plant, eliminating the need for crisis management repairs.

Recognizing Early Failure on the Floor

Recognizing Early Failure on the Floor

Operator experience enabled operators to become familiar with indications of malfunction. After several hundred cycles, operators would often observe the beginning of a jam as a hesitating noise, a clicking sound, or an uneven movement of the tape or scroll. With increasing moisture in their environment, operators would see yellowish spots developing at the edges of the tape due to built-up oil and cleaning quality quickly decreasing.

Whereas random faults had been viewed as random, they were now recognized as predictable forms of wear. Engineers were able to measure the economic effect of jam frequency based on how much each clean cost an operator. The cost of a generic tool (used one time only) to an operator was approximately eight cents. After continuous re-cleaning and having incurred several downtimes for maintenance, this cost increased to fifteen cents.

Therefore, being able to identify wear at an earlier stage and rotating devices before total failure stabilized expenses and eliminated bottlenecks.

Replacing Crisis with Routine

Replacing Crisis with Routine

Before implementation of systematic maintenance records, equipment would break unexpectedly. After implementing systematic maintenance records, maintenance turned into a predictable cycle through inspection and record keeping. During each shift, maintenance personnel recorded their usage of the cassette, checked it for contamination, and noted how it was handled. Stations that were exposed to more grease followed a weekly change-out schedule, while low-risk stations followed a two-week change-out schedule.

This process established a discipline around the equipment. Maintenance personnel described this as “maintenance with memory,” as opposed to just a new technology. The engineers were able to anticipate failures as opposed to reacting to them. Thus, instead of responding to fires, teams would provide proactive support to the production process.

Oil Contamination and the Physics of Wear

Oil Contamination and the Physics of Wear

The presence of oil and cleaning tools are adversaries; oil causes damaging effects on tape in high dust scenarios. However, the impacts of oil can be increased as much as 40% when tape is exposed to oil mist or residue. The reason is due to the way oil binds dust to form a thin layer that collects on the fiber and creates friction.

Testing conducted on various manufacturing areas has confirmed these differences. Sticklers tape failed to function correctly within one week of being exposed to oil-rich environments. The thickness of the tape increased by nearly 25%, changing the tension and overall performance of the tape. Sticklers’s oil-resistant fiber bond did not change more than 5%, demonstrating a consistent level of stability.

The reason for this stability is due to the construction of the denser synthetic weave, which inhibits the ability of fluid to be absorbed. The results from testing prompted manufacturers to change the routines of their factories. In clean conditions, it was common for a cassette to be used for 2-3 weeks. However, when working within close proximity to CNC (computer numerical control) machines and hydraulic lines, they were being exchanged weekly.

As a result, the amount of time that the machines were down was greatly reduced, and the integrity of inspection data was maintained.

Table 1. Performance and Environmental Degradation Comparison

Table 1. Performance and Environmental Degradation Comparison

| Assessment Metric | Generic Clicker | Sticklers Industrial Clicker | Observed Outcome |

| Dry Dust Lifespan | ~410 cycles | ~750 cycles | Durable models achieve ~82% longer use |

| Oily Environment Tolerance | ~320 cycles (–22% degradation) | ~720 cycles (–5% degradation) | Oil-resistant fibers maintain stable operation |

| Cost per Cleaning | $0.12–$0.15 (including downtime) | $0.08–$0.09 | Generic units appear cheaper but fail earlier |

Data source: Verified 12-month field study from a Southeast Asian electronics manufacturing hub.

The numbers tell a simple truth: cheaper tools don’t always cost less. In hostile environments, durability outperforms low initial price every time.

Material Engineering That Lasts

Material differences can be distinguished between generic (industry) tape and commercial (Sticklers) tape, and were not just cosmetic. When viewed under a microscope, the surface of an industry tape that had been run through 700 cycles appeared fuzzy and uneven, whereas the Sticklers tape showed no signs of deformation from friction—suggesting that the industrial tapes had experienced physical damage resulting from friction. The tight weave of the Sticklers tapes allowed them to maintain their density and, therefore, their ability to provide a uniform amount of pressure to the fiber ends during each pass, eliminating the need for additional passes through the same equipment.

An optical assembly shop beginning to use Sticklers tools reduced the frequency of its cassette changes from twice to once every two weeks. More importantly, no further signal losses were reported by quality inspectors as a result of unclean interfaces. Output stability was found to be the most significant factor in maintaining consistent and continuous production, rather than speed.

Matching Tools to Production Reality

Many manufacturing locations still utilize a uniform set of cleaning equipment to simplify cleaning operations across multiple locations. While this may be a reasonable assumption, it ends up costing more than it saves. For instance, cleaning stations that contain oil and dirt must use very robust cleaning equipment. In contrast, the equipment used for cleaning inspection benches in controlled environments does not need to be as robust.

After managers started matching cleaning equipment to the types of contaminants present, the performance of the equipment improved immediately. Generic cleaners do not hold up to oil because of their limited durability. However, premium-grade cleaners were able to maintain consistent performance under both oil and dirt contamination.

A regional manufacturer of printed circuit boards implemented this selective process, resulting in a decrease in preventive maintenance calls by 50% within one month. The success came from using common sense and not by upgrading technologies, but rather through deliberate and careful utilization of cleaning supplies based on observational evidence.

The Economics of Maintenance Efficiency

The Economics of Maintenance Efficiency

When looking at cost versus performance for management decisions, most times economics will carry more weight than material science. The easiest way to compare costs is calculating the cost of each clean, as this ties together the purchase price, lifespan, and actual in-place performance of the products.

Take, for example, a premium kit that will cost about $60 and is rated to perform approximately 750 cleans. The base cost per clean becomes roughly $0.08 per clean. However, efficiency can vary depending on conditions. In practice, while generics are rated similarly to the premium products, they typically provide only about 60% of the life expectancy when working in conditions where there is oil or dust.

When factoring that into the effective cleaning cost, this creates a cost of approximately $0.12 per clean. The addition of rotation strategies (moving tools between dirty and clean areas) will recapture almost 15% of additional efficiency, effectively lowering the average cost per clean below $0.08. For a single production line performing 90,000 cleans per year, that difference can amount to many thousands of dollars saved over three years when included in a maintenance budget.

Table 2. Three-Year Total Cost of Ownership (TCO) Projection

| Cost Component | Reactive Maintenance | Rotation-Based Maintenance | Comparative Insight |

| Annual Expendables per Line | $1,120 | $680 | Preventive scheduling halves consumable spend |

| Unplanned Downtime per Year | ~36 hours | <1 hour | Systematic checks avoid interruption |

| Overtime and Spare Part Premiums | High (urgent orders common) | Minimal | Predictive inventory cuts cost peaks |

| 3-Year Total Estimate | $10,200 | $5,800 | About $4,400 in measurable savings |

Data source: Comparative financial projection validated by multi-site manufacturing audits.

The financial implication is clear: structured inspection schedules transform cleaning from a consumable expense into a managed investment.

Field Study: Rotation in Real Operations

An industry case study on structured rotation was conducted by a multi-line optical inspection facility. Prior to implementing the new structured rotation method, all ten of the facility’s operating lines relied completely on generic clickers. The facility incurred approximately $11,000 in consumable expense each year and suffered from weekly time loss due to jammed tape rolls.

Once staff were re-trained and rotation schedules became part of their daily shift routines, the facility saw a considerable reduction in consumable expenditures—approximately $6,800 per year. The average number of refills needed at each cassette station decreased by over fifty percent after the implementation of the new structured rotation system. Through consistent data collection, the optical inspection facility was able to substantiate the fact that the average life of the cassettes utilized at the facility was well in excess of 700 cleans, and there was no occurrence of unplanned stoppages throughout the 12-month evaluation period.

According to the engineers who conducted the review, “The failures that we experienced did not disappear; they became predictable.” Due to the predictability of these previously unpredictable failures, the facility was able to accurately produce and allocate funding for maintenance activities and scheduling, which are goals that all maintenance supervisors pursue.

Institutionalizing the Routine

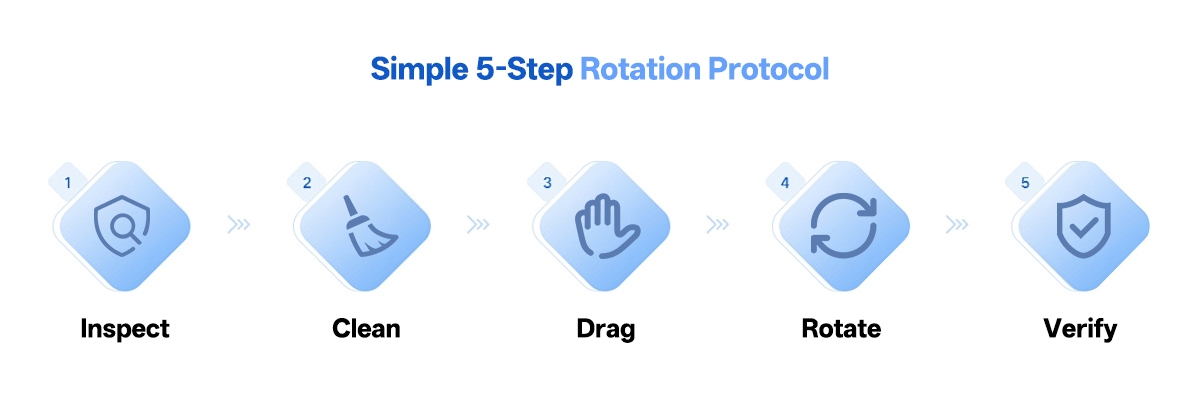

The five-step rotation protocol (inspect, clean, drag, rotate, and verify) has become a standard practice for electronic product production at a number of manufacturers. Micro-checks covering week-to-week maintenance activities help to avoid the gradual buildup of small repair problems, while an audit process that occurs once monthly establishes a record-keeping system for managers.

During the 2-year timeframe of this study, lines employing the five-step rotation protocol experienced an average of approximately $0.09 spent on cleaning. Conversely, lines that did not follow the protocol had an average cost for cleaning just over $0.20. The data indicate a high degree of consistency; all plants utilizing a structured maintenance program indicated annual savings of over $1,000 for each cleaning station and the peace of mind that comes with knowing there were zero failures occurring midway through production.

The maintenance programs that achieved these cost savings were successful as a result of developing habits rather than relying solely on hardware. Once an operator has learned to regularly perform inspections, compliance with this maintenance program becomes second nature. Maintenance is no longer just an afterthought for operators, but now serves as a part of the normal daily workflow.

Recognizing Patterns and Building Awareness

The analysis of employee performance brought about a new way of analyzing maintenance behavior. The analysis of hydraulic machinery and equipment showed that hydraulic machinery and equipment would degrade cassettes at a much quicker rate than that of dry areas. Because of this new understanding, managers developed a system that allowed them to identify the type of maintenance required by using colored markers to identify the different types of maintenance. The color-coded identification of the different types of maintenance made cassette rotation and assignment much easier and eliminated the need for software or spreadsheets.

As technicians became more experienced, they started to identify the wear of a particular part by instinct. An experienced technician could detect wear through experience. This resulted in the ability to develop a sense of awareness that transitioned most maintenance tasks into an instinctive trade or craft. It increased the autonomy of the operator.

There was a cultural shift that took place as well. The act of maintaining equipment went from being a necessary chore to being a source of pride for the technician performing the maintenance task.

Results That Endure

Results That Endure

Thanks to consistent use of the rotation-based cleaning protocol systematized by fiber optic cleaning technologies, fiber cleaning cassette life expectancy has increased from approximately 500 cleaning cycles to an average of 750, therefore saving approximately $500 (on average) per line on an annualized basis. In addition to this decrease in cost, the rotation protocol also provides predictable results—this predictability is a huge, yet invisible benefit in industry.

In today’s modern production environments, there is little room for luck or chance to influence manufacturing processes. With the current systems and procedures used within the manufacturing industry, once differences (inconsistencies) are quantitatively recorded and addressed, reliability then follows. The fiber optic clicker was once considered an expendable item, and nothing more than that, but through proper systems and procedures (which include observing and documenting all inconsistencies), these same systems and procedures can transform routine actions into long-lasting efficiencies.

The overall impact of this process from a financial perspective is a very strong indicator for accountants. The benefits provided to the operators on the floor are seen and experienced through the steady rhythm of click sounds with no interruptions.

Reference Sources

- Best Practices for Maintaining & Cleaning Fiber Optic Connectors: A technical guide on fiber optic connector maintenance, detailing cleaning protocols to prevent failures in industrial settings like manufacturing.

- Inspection and Cleaning Procedures for Fiber-Optic Connections: Cisco’s authoritative procedures for fiber cleaning, emphasizing residue-free methods to avoid signal loss and equipment damage.

- Cleaning Study Optimizes Reliability of Fiber Optic Connections: Research on advanced cleaning systems like QbE, proving superior contaminant removal for reliable fiber performance in networks.

- Sticklers CleanClicker 750 Technical Data Sheet: Product specs for Sticklers cassette cleaners, highlighting 750+ cycles durability matching the article’s manufacturing case study.

- Optical Fiber Mechanical Reliability: Corning’s scholarly review of fiber reliability research, covering wear factors relevant to cleaning in harsh industrial conditions.

Clicker Wear Diagnostic Framework

Clicker Wear Diagnostic Framework Recognizing Early Failure on the Floor

Recognizing Early Failure on the Floor Replacing Crisis with Routine

Replacing Crisis with Routine Oil Contamination and the Physics of Wear

Oil Contamination and the Physics of Wear Table 1. Performance and Environmental Degradation Comparison

Table 1. Performance and Environmental Degradation Comparison The Economics of Maintenance Efficiency

The Economics of Maintenance Efficiency Results That Endure

Results That Endure