Fiber Optic Cables

Armored vs. Indoor/Outdoor Fiber Optic Cables: How Patch Cables Connect

Fiber optic cables provide a variety of solutions for network cabling and industrial connectivity. Ranging from armored fiber optic cable, which can be engineered for rugged use, to flexible indoor/outdoor fiber optic cable in building infrastructure. Each product addresses a specific requirement. Choosing is not only a technical consideration but also ensures that the correct design is suited to address the user’s real-world installation challenges, whether campus networking or high-speed home fiber optic internet. Globally published industry data in 2025 shows that new fiber optic patch cable systems now drive more than 70% of enterprise network refreshes, which clearly indicates the impact that new fiber optic types can have on the overall ability to create a reliable, low-loss method of communication. This practical experience, along with recent industry data, gives the user guidance on which fiber optic types and patch cable connections will provide the best option for any type of installation.

Showing all 43 results

0.9mm GJFJV Tight Buffer Fiber Optic Cable – Single-Fiber Indoor, LSZH/PVC Jacket, Aramid Strength Member

Price range: $0.09 through $1.50

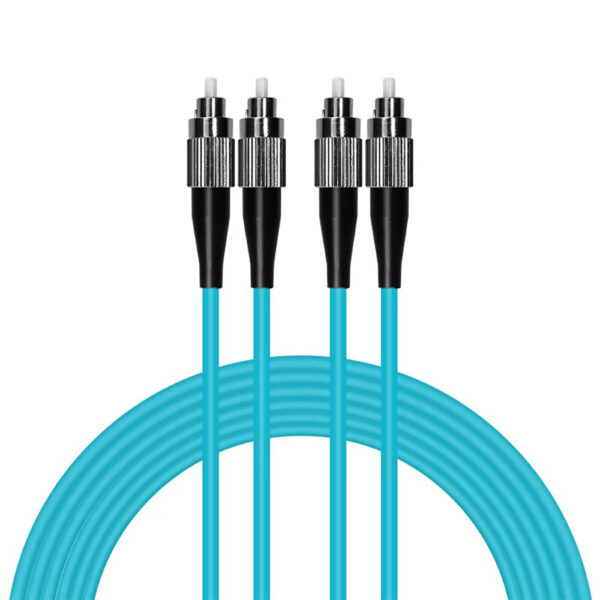

50/125µm Multimode OM3 Fiber Patch Cable, FC UPC to FC UPC Duplex, 10Gb, LSZH

Price range: $6.39 through $26.80

Custom Fiber Optic Cables, LC/SC/FC/ST/MU/MTRJ Connectors, Duplex Single Mode OS2, 9/125μm

Price range: $6.20 through $19.99

Customized Multimode OM3 Fiber Optic Patch Cord, Duplex, LC/SC/FC/ST/MU Connectors, UPC/APC Polish, LSZH Jacket

Price range: $5.90 through $42.00

Customized OM1 Multimode Simplex Fiber Optic Breakout Cable, 62.5/125μm, OFNR, Indoor, Tight-Buffered

Price range: $0.60 through $599.00

Customized OM3 Multimode Simplex Fiber Patch Cable, LC/SC/FC/ST/MU Connectors, UPC/APC Polish, 2.0mm Tight-Buffered, Aqua

Price range: $3.30 through $15.80

Duplex OM2 Fiber Optic Cable 50/125µm, Multimode, Indoor, Riser (OFNR/LSZH), 4/6/8/12/24 Fibers

Price range: $0.79 through $769.00

FC UPC Simplex to FC UPC Simplex Fiber Patch Cable, Single Mode, 9/125μm, LSZH, 2.0mm Tight-Buffered, Yellow

Price range: $4.98 through $12.90

FC/UPC to LC/UPC Fiber Optic Patch Cable, Singlemode OS2, Duplex, 9/125μm, PVC

Price range: $4.20 through $12.80Figure 8 Fiber Optic Cable GYTC8S 9/125μm G652D Singlemode, Customizable 4–144 Core Outdoor Aerial Cable

Original price was: $26.00.$12.00Current price is: $12.00.GCYFTY Outdoor Air Blown Micro Fiber Optic Cable, G.652D SM, Stranded Loose Tube, 4-144 Cores HDPE Jacket

Original price was: $6.00.$1.00Current price is: $1.00.GCYFXTY Outdoor Air Blown Micro Fiber Cable, Central Loose Tube, G.652D SM, 2-24 Cores, Low-Friction HDPE Jacket

Original price was: $2.00.$0.50Current price is: $0.50.

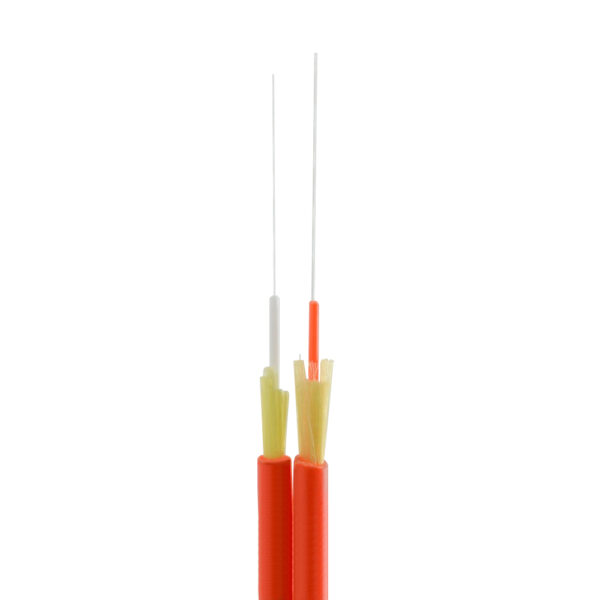

GJFJBV Flat Duplex Tight Buffer Fiber Optic Zipcord Cable, 2mm/3mm, Indoor

Price range: $0.09 through $5.00

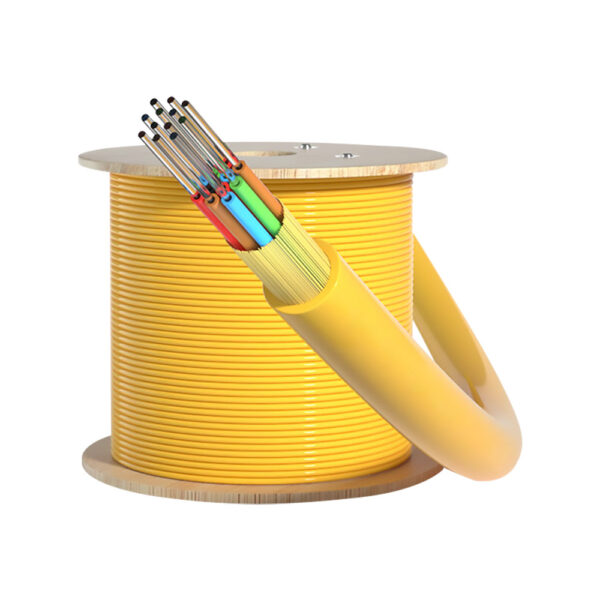

GJFJH Fiber Optic Bundle Cable, Telecom-Grade Single Mode LSZH, 4/6/8/12/24 Core

Price range: $0.28 through $3,259.00

GYFTY/GYFTZY Stranded Loose Tube Fiber Optic Non-Metallic Sheathed Cable, Flame Retardant, EMI Resistant, Outdoor, 2 ~ 216 Core

Price range: $0.40 through $369.00

GYTA Aluminum Armored Fiber Optic Cable, G.652D, Loose Tube, 2 to 288 Cores, Outdoor

Price range: $0.49 through $9,999.00

GYTA53 Direct bury Fiber Optic Cable, Steel Double Armored, Low Attenuation, Outdoor Cable

Price range: $0.70 through $1,500.00

GYTZA Armored Fiber Optic Cable, Stranded Loose Tube, Aluminum Tape, Flame Retardant LSZH, Outdoor Cable Tray & Conduit, 2-288 Cores

Price range: $0.60 through $499.00

GYXTW 2, 4, 8, 12, 24 Core Central Tube Outdoor Armored Fiber Optic Cable for Cable Tray & Conduit

Price range: $0.10 through $700.00

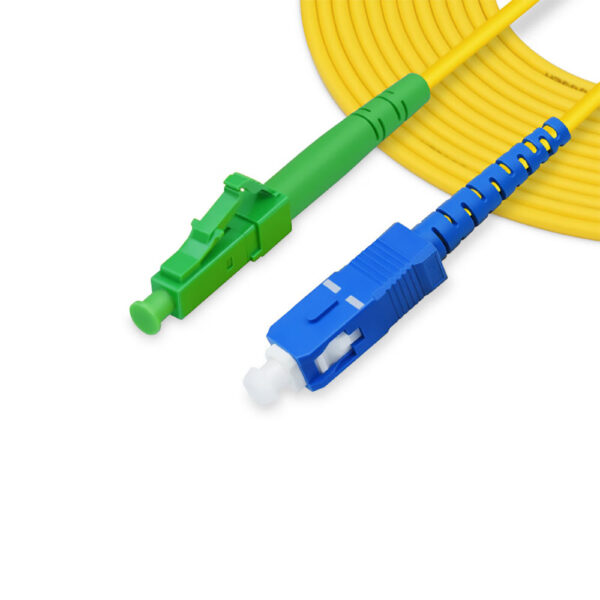

LC APC to SC UPC Single Mode Fiber Patch Cable, Riser (OFNR), 2.0mm, Tight-Buffered

Price range: $3.29 through $4.99

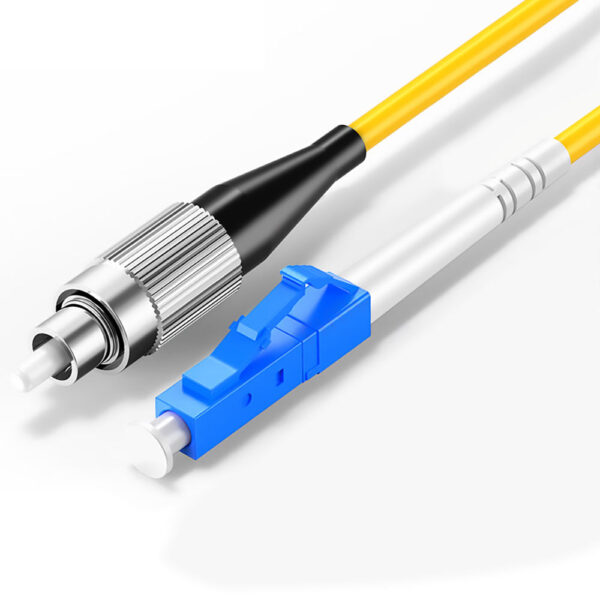

LC UPC Simplex to FC UPC Simplex Fiber Patch Cable, Single Mode, Telecom Grade

Price range: $2.90 through $5.50

LC UPC Simplex to LC UPC Simplex Single Mode Fiber Patch Cord, 9/125, OFNR, 2.0mm

Price range: $5.90 through $14.90

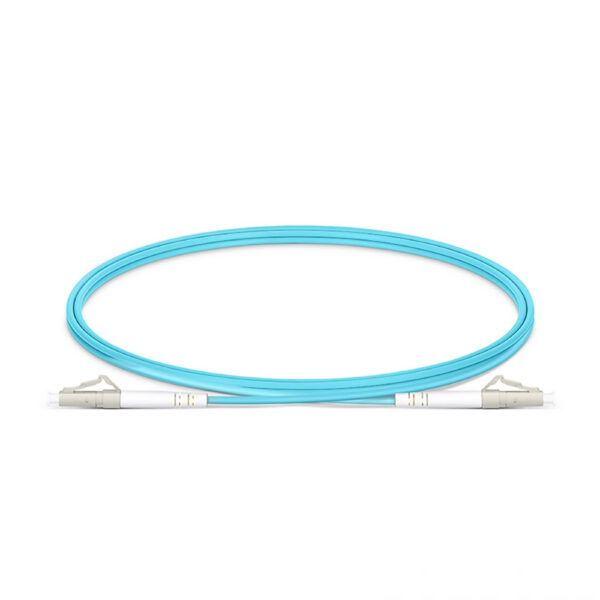

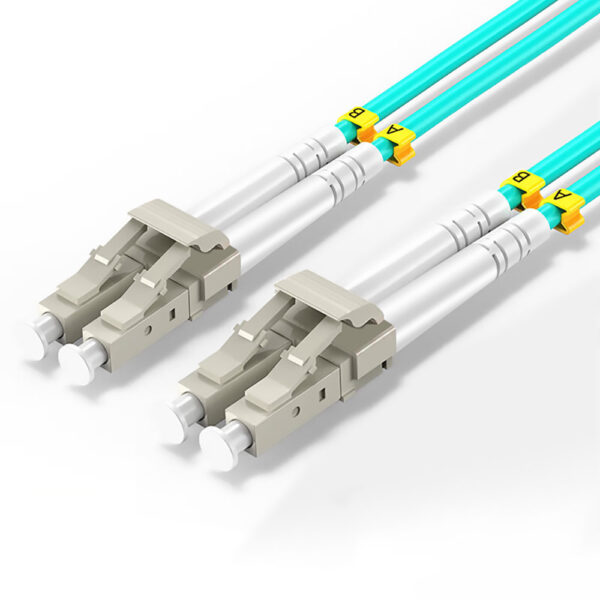

LC UPC to LC UPC Duplex Fiber Patch Jumper Cable, 2m (7ft), Multimode OM3, 10Gb, LSZH, 50/125, 2.0mm, Tight-Buffered

Price range: $11.90 through $17.50

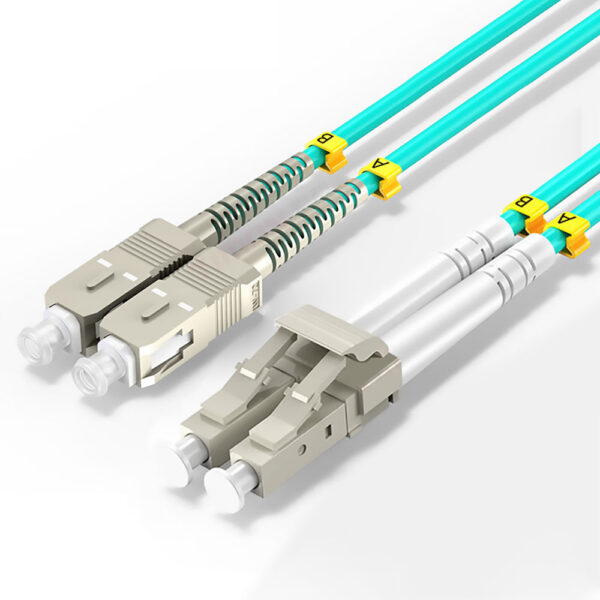

LC UPC to SC UPC Duplex Fiber Patch Cable, Multimode OM3, 10G, LSZH, 10m (33ft), 2.0mm

Price range: $9.90 through $13.90

LC-LC 1m(3FT)/2mm Duplex Single Mode Fiber Patch Cable, UPC, LSZH, Yellow (1m, 2m, 3m, 5m)

Price range: $7.90 through $11.60

LC/SC/FC/ST/LSH Armored Anti-Rodent Fiber Optic Pigtail, Customized 2-48 Fibers OS2 Single Mode

Price range: $14.00 through $59.00

LC/SC/FC/ST/LSH Bundle Fiber Optic Pigtail, Customized 4-96 Simplex OS2 Single Mode Fibers for ODF

Price range: $17.00 through $176.00

LC/UPC to SC/APC Patch Cables, Duplex Single Mode (OS2), 2 Fibers, 9/125µm

Price range: $6.50 through $16.90

LC/UPC to SC/UPC Duplex Fiber Patch Cable, Single Mode (OS2), PVC/LSZH, 2.0mm

Price range: $9.80 through $16.70

LSZH Fiber Optic Cable – Steel Butterfly GJXH-1,2,4B6 FTTH Indoor Drop Cable

Price range: $0.16 through $9.80

LSZH QS Cable – GJYXCH FTTH Steel Butterfly Fiber Optic Cable for Indoor/Outdoor

Price range: $0.28 through $229.00

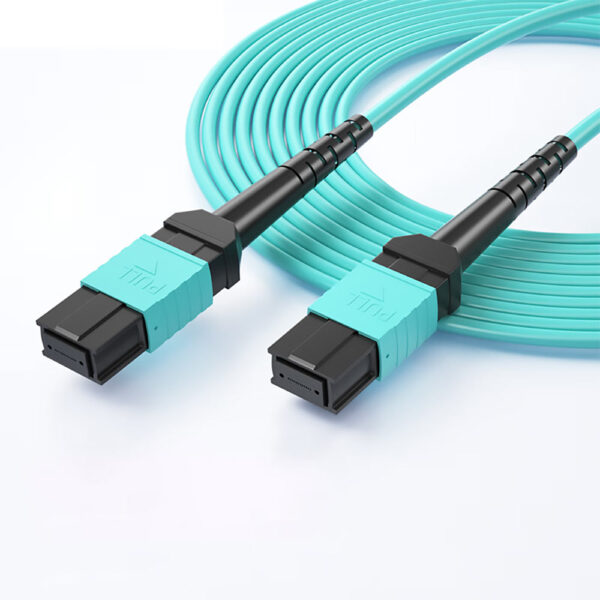

MPO to MPO Patch Cable, OM4, 8/12/24/48 Fiber, Type B, Female to Female, LSZH, 40G/100G MPO Cable

Price range: $126.00 through $259.00

MTP to MTP OM4 12 Strand Multi-Fiber Patch Cable, Type B, Female-Female, LSZH, UPC, 100G

Price range: $109.00 through $169.00

MTP/MPO to MTP/MPO 12 Strand Female Multi-Fiber Patch Cable, OM4, Type B, OFNP, 100G

Price range: $145.00 through $279.00

OM3 24 Core Loose Tube Fiber Optic Breakout Cable, Tight-Buffered, LSZH Jacket, 10Gbps Multimode

Price range: $0.29 through $299.00

OM4 50/125 Multimode Loose Tube Fiber Optic Cable, 10/40/100Gbps, LSZH Jacket

Price range: $0.80 through $829.00

Outdoor ADSS Fiber Optic Cable – Single Mode, 6/12/24/48/64 Core, PE Outer Sheath

Price range: $0.49 through $6.00

Outdoor GYTS 4 Core Aluminum Armored Aerial Duct Fiber Optic Cable, 2-288 Core Optional, Loose Tube

Price range: $0.60 through $1,100.00

SC to SC Single Mode Simplex Fiber Patch Cable, 9/125μm, LSZH Flame Retardant

Price range: $4.98 through $16.00

SC UPC to FC UPC Duplex Fiber Optic Patch Cable, Multimode OM3 10Gb, 50/125μm, LSZH

Price range: $4.90 through $52.00

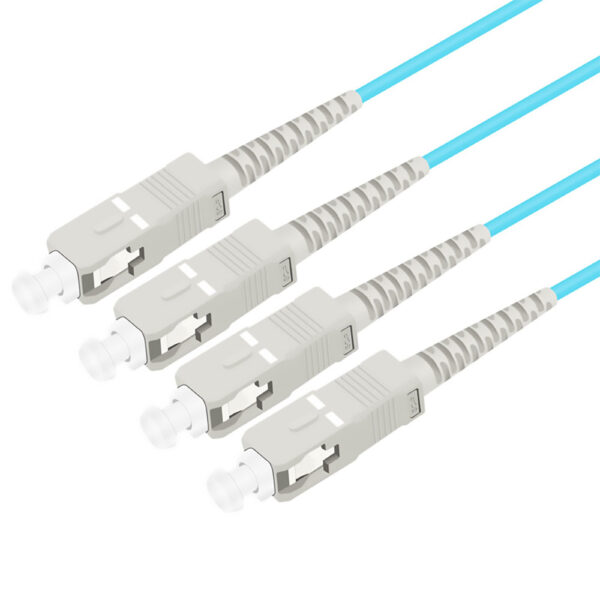

SC UPC to SC UPC OM3 Multimode Fiber Patch Cable, 50/125µm Duplex, 10Gb, LSZH, Data Center Grade, 0.1dB Insertion Loss

Price range: $5.99 through $29.98

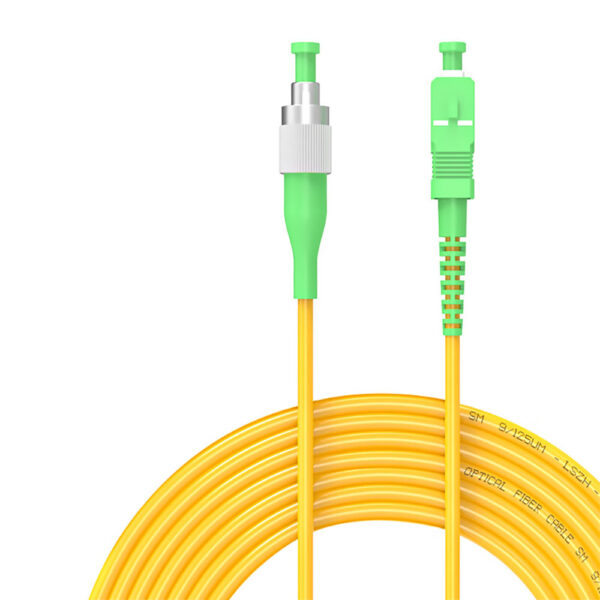

SC/APC to FC/APC Simplex Fiber Patch Cable, Single Mode, 9/125, 2.0mm, Custom Length

Price range: $3.35 through $32.99

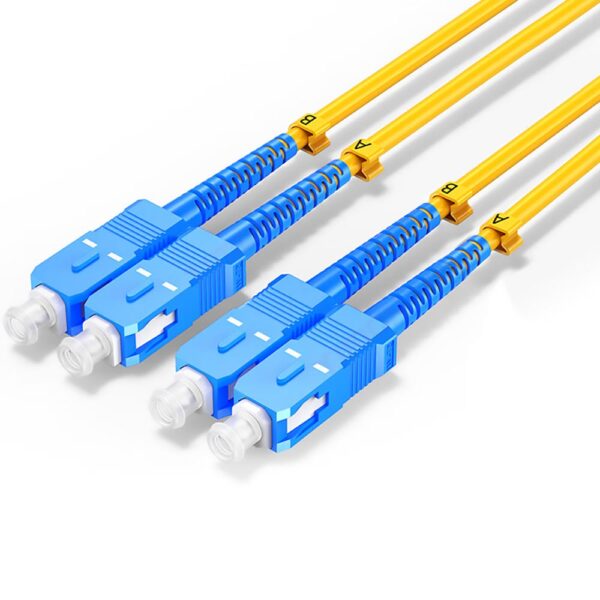

SC/UPC to SC/UPC Duplex Fiber Patch Cable, Single Mode 9/125μm, 2.0mm, OFNR Riser, 2 Fibers

Price range: $4.60 through $9.60Understanding Armored and Indoor/Outdoor Fiber Optic Cables

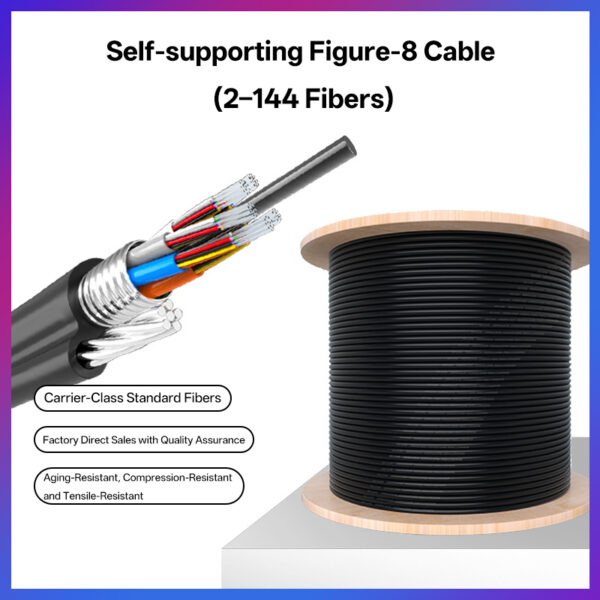

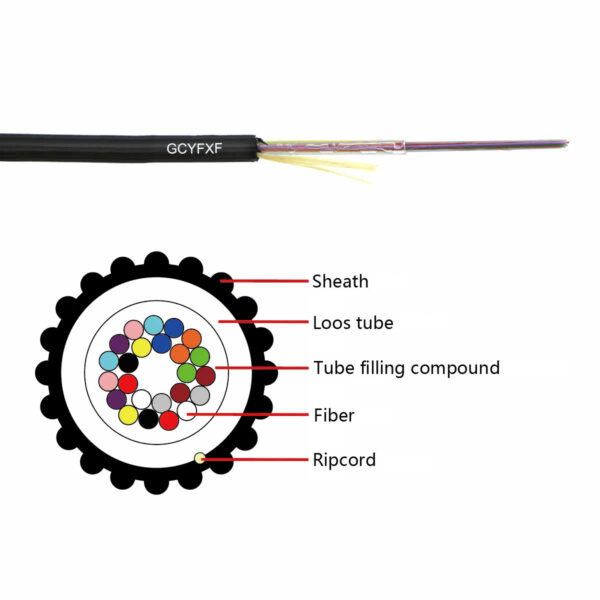

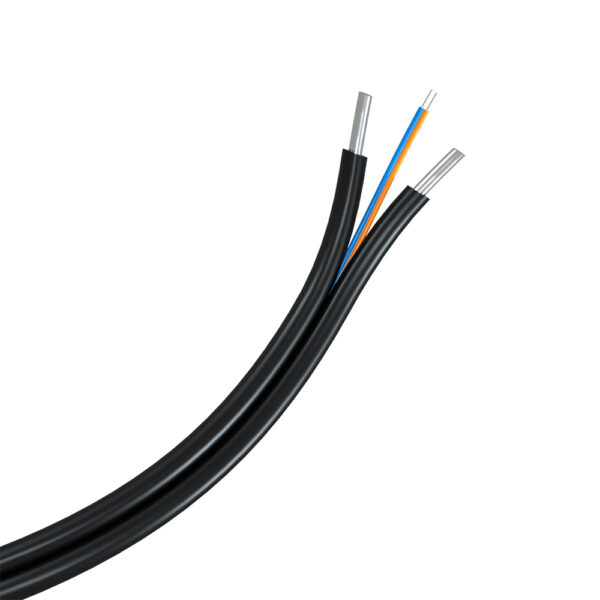

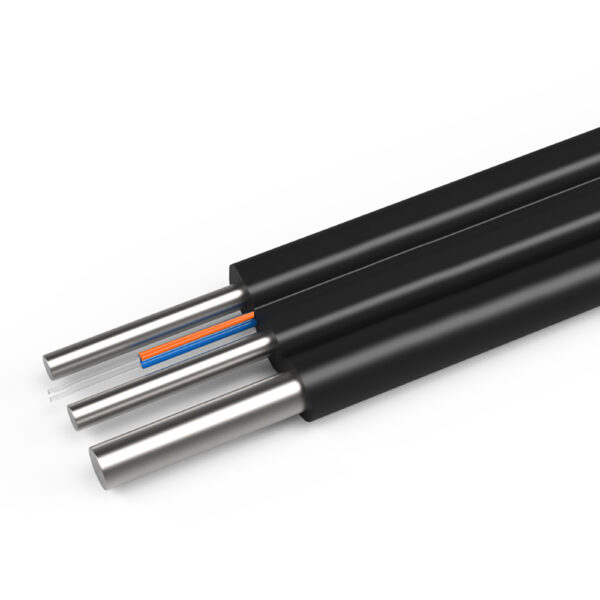

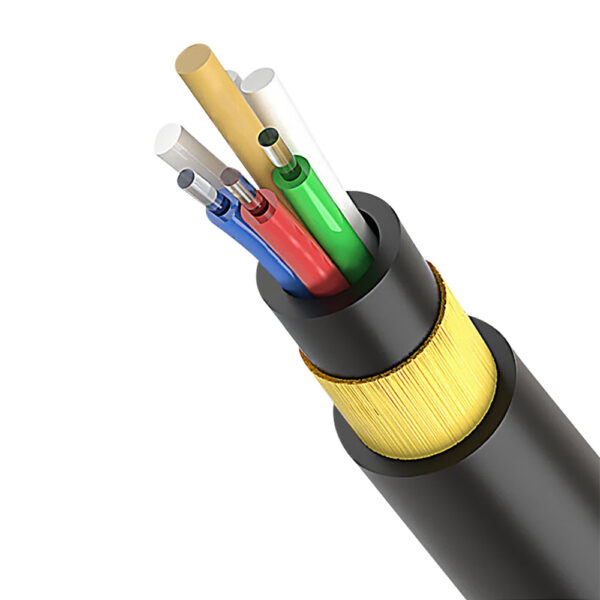

Armored fiber optic cable is designed for the most high-risk environments. It is protected against rodents, moisture, and accidental cuts by a metal shield. Indoor/outdoor fiber optic cable has, at least, multiple plastic jackets providing enough resilience for the flexing required from outdoor environments into offices or risers where the elements and bending are the main concerns.

I recall a factory job where loss of data simply couldn’t happen. We used armored fiber optic cable to give us peace of mind when installing underground fiber optic cable, and we were up against heavy equipment and wildlife. On the other hand, we were to connect multiple buildings on a school campus, and the flex of the indoor/outdoor fiber optic cable was great for routing through ductwork, with ease of transition to humidity and UV.

Whether protecting against construction deterrents in industrial areas or integrating your network into a commercial building, selecting the type of fiber optic cable will always ensure your connection is reliable and bulletproof. There were lessons and experience learned with every project - we learned it was easier to select the fiber optic cable for both our complete installation and the environment, not just from the specification or code requirements but from the on-ground experience and risk.

Single-mode vs Multi-mode Fiber: What You Need to Know

Single-mode fiber optic cable (for example, OS1 and OS2) uses a very small 9μm core that will restrict, or keep light traveling along a single mode. This essentially means very little signal loss over long distances. In fact, single-mode fiber optic cables are generally the backbone of a city's network or a data center, and can run up to 40km, or even longer.

Campuses and larger enterprises tend to choose single-mode (sold as OS1 or OS2) because it helps provide greater connectivity reliability and speed when connecting to far away buildings or pathways.

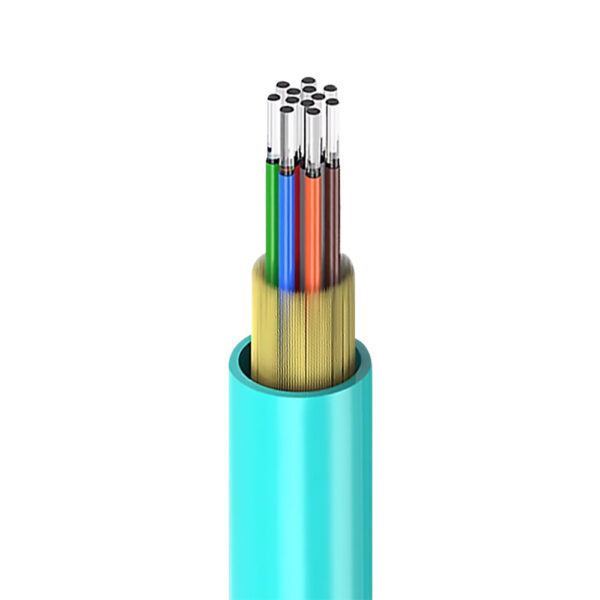

Multi-mode fiber optic cable uses OM1, OM2, OM3, OM4, or OM5, and the core size is much larger (50μm or 62.5μm), allowing the light to travel as multi-modes (as compared to 1 mode with single-mode). This is often used in short runs in the office, on one floor, or closet to closet with a data closet. This is an ideal multimode fiber optic cable and supports 40Gbps up to 100m or more with OM3 and OM4. In conclusion, most home users or smaller enterprises are likely to choose multi-mode due to its balance between high bandwidth and high cost efficiency across a relatively local connection.

| Type | Core Size | Bandwidth (MHz·km) | Color | Max Distance at 10Gbps |

| OS1/OS2 | 9μm | Unlimited | Yellow | 10,000m+ |

| OM1 | 62.5μm | 200 | Orange | 33m |

| OM2 | 50μm | 500 | Orange | 82m |

| OM3 | 50μm | 2,000 | Aqua | 300m |

| OM4 | 50μm | 4,700 | Aqua | 400m |

| OM5 | 50μm | 28,000 | Lime Green | 400m |

Fiber optic cable manufacturers produce both types for different applications. I’ve assisted fast-growing offices in upgrading to OM4 multi-mode fiber for file servers, allowing them to keep costs reasonable and their speed at a decent rate. I’ve also assisted factories with large connection sites in upgrading to single-mode fiber optic cables while eliminating issues with lapses and slower speeds.

To determine the appropriate fiber optic cable for your situation, it always begins with, "Is your run a longer distance or shorter distance? Are you wiring in a home, office, or on a campus?" Selecting an appropriate type of fiber based on your true situation will address costs and performance. If you are still not sure, please reach out to fiber optic cable manufacturers or a skilled installer with their previous installations. They have generally witnessed similar scenarios.

Simplex and Duplex Fiber Optic Cables Explained

Simplex fiber optic cables only use one fiber strand, and therefore, the single-mode and multi-mode fiber optic options are typically for one-way data transmissions—like what you would use for sensor links or modest monitoring. Conversely, duplex fiber optic cables use two fibers that can send two-way transmissions side by side. This capability is a requirement for the majority of office networks, as data centers are in a constant state of continuous data flow. The choice between simplex and duplex fiber optic cabling is scene-dependent on the specific network topology.

For example, I recently conducted a network upgrade in an office building that had racks where the equipment was "daisy-chained" connecting switches, and it required duplex fiber optic patch cables so there could be continuous flows of data sent in both directions. Security cameras placed outside along the perimeter of a building were using simplex fiber optic network cabling, so each camera was connected back to the control room directly, to keep things simple and within budget.

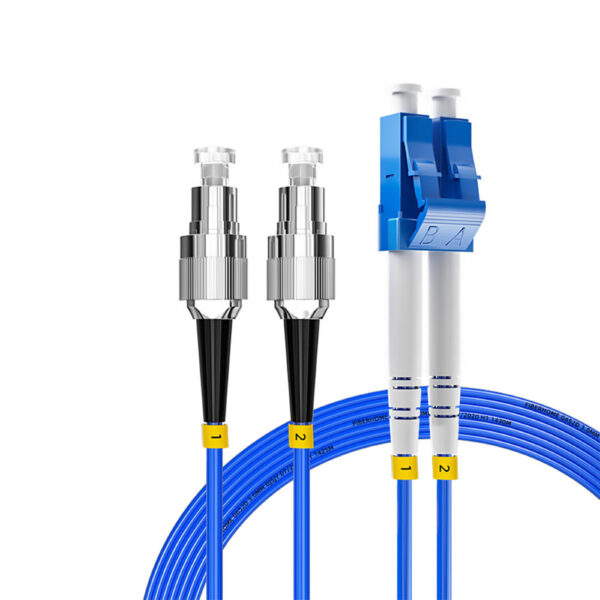

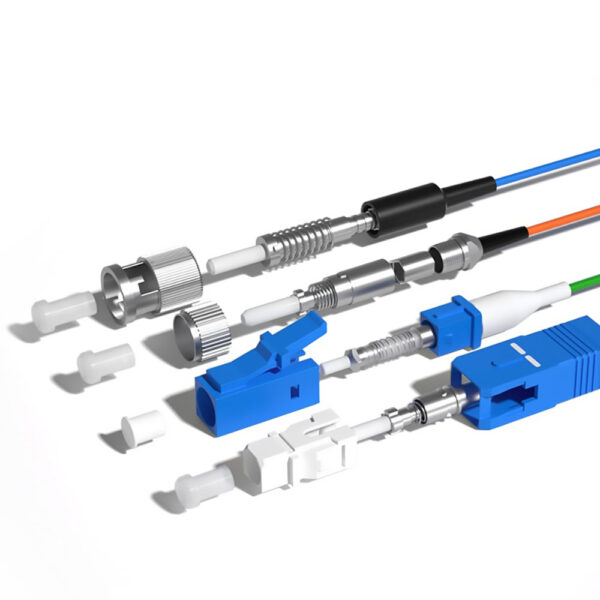

In both situations, attention must be given to the types of fiber optic connectors that are used with the fiber cables. Fiber patch cables used inside a switch will have duplex LC or SC connectors on the ends, whereas simplex fiber optic connectors will work where signals must only go downstream or in one direction.

In both cases, the correct balance to install fiber optic cabling is between network and installation efficiency.

Direct Buried vs Armored Fiber Optic Cable: When and Why

Direct buried fiber optic cable is a type of fiber optic cable that is made to be buried directly in the ground without any additional conduit. This type of fiber cable has a thick water-blocking layer and jacket that has the ability to withstand the pressure of the soil, moisture, and temperature. Armored fiber optic cable has a secondary layer of protection, usually made of a metal sheath, that provides a higher level of protection against bites from rodents, crushing forces, and is the best choice for installation when the cable will be exposed to mechanical forces.

While working on the expansion of an industrial site, our team needed to connect several outbuildings, each hundreds of meters apart, in one of the outbuildings. Along the driveway, which had a lot of vehicle traffic, we used armored fiber optic cable to protect against a loader accidentally digging into the cable or crushing it because of a loader or large vehicle driving on top of the cable. Across open grassy space where only moisture and freezing temperatures would be a risk, we used direct buried fiber optic cable.

The performance of direct buried fiber optic cable and armored fiber optic cable does vary in cost as well. Armored fiber cable is the more expensive option that provides a greater level of performance and protection, while direct buried fiber optic cable can lower costs, but should only be used in non-aggressive applications.

| Cable Type | Protection Level | Installation Cost | Best Used For |

| Armored Fiber Optic Cable | High | Higher | Industrial or risk zones |

| Direct Buried Fiber Optic Cable | Medium | Lower | Open fields, soft soil |

Making smart choices includes evaluating your work route for digging hazards, wildlife, and equipment relocation. In some cases, mixing both on the same property gives the right mix of security and budget control.

How Fiber Optic Patch Cables Link Armored and Indoor/Outdoor Fibers

Fiber optic patch cables fulfill a critical role in connecting armored fiber and indoor/outdoor fiber optic cables as the flexible link in any modern network. Patch cables provide the ease of connecting devices, patch panels, and types of cables without splicing fiber and causing outages. The significance of patch cables manifests quickly when the layout changes or hardware changes, usually in offices and data center-type environments.

Reliability in a connection requires accuracy in connector match-ups. For patch cables, LC and SC connectors are common connector types used to make a secure and easy snap-in connection for either single-mode or multi-mode patch cables. Compatibility is vital, because when extending the backbone armored fiber into an indoor section, you want to be careful to match the physical types of connectors as well as the types of cables (single-mode or multi-mode) to avoid very expensive mistakes.

I experienced a prolonged connection issue at a distribution facility that arose after a new switch was added to the network. The source of our connection problem was discovered to be a matching problem with the cable connectors (one was SC, the other LC) and an overlooked single-mode/multi-mode connector type conflict. The corrected cables in the exact configuration that allowed the fiber optic patch cables to stabilize the data flow almost instantly. Again, this experience just re-emphasized the importance of checking connector type/mode compatibility and length before plugging a new segment into the network.

For better performance and better maintenance time in the future, patch cables should be short, clearly labeled, and have the correct fiber optics specifications for future bandwidth. The return on investment in fiber optic patch cables for network performance and maintenance means time, money, and troubleshooting saved down the road by investing in the right connector type and cable compatibility.

Installation Best Practices and Latest Industry Standards

To install fiber optic cables correctly, start with route planning and duct preparation. Make sure all bends in the fiber optic cable are gentle; acute angles can degrade the signal. Color-coded cables for each link that you plan to install—and a solid fastener—will mitigate any potential confusion down the road when a future upgrade or repair is needed. When ordering cables or connectors for the installation, ensure these are suitable for supporting 40G or 100G along the link. Be certain that any new equipment is also rated for high-frequency data throughput—this will also ease any transitions down the road.

I once upgraded an entire office, then wrongly pulled fiber optic HDMI cable through too sharp a turn in the conduit. It micro-cracked almost immediately, causing the internet signal to drop on and off. Rerouting the HDMI line and adding some fiber guides eliminated the issue permanently, but I learned several valuable lessons: respect the bend radius of all cables and inspect the cables before covering them within a wall or ceiling.

In most cases now, we strongly recommend testing each installed run with modern testing equipment during a fiber optic installation, not just a visual inspection. In spite of the broadband fiber optic vs. cable thought process around reliability, which may hold some weight, we still need to comply. Upon compliance, we should expect a strong and low-loss signal if everything up to this point is compliant and continues to comply with best practice guidance. Whenever new technology is released, keeping everything current with best practice guidance on installation and network/technical guidance will keep every network installation strong, safe, and updated for fast, repeatable upgrades.

FAQ:

How do I know the difference between the different OM fiber types?

When I need to check the type of cable installed, I typically check for color coding on the sheath. OM1 is typically orange with a 62.5μm core, or OM3 and OM4 are typically aqua blue with a 50μm core. Most fiber optic cable manufacturers label these specs clearly on the cable to confirm the same specs match the patch cable when required during an upgrade or replacement.

When do I really need armored fiber optic cable?

I always leave it to my judgment when laying fiber optic cable, but I use armored fiber optic cable if the line is going to be laid underground or run across a busy work area or in proximity to heavy machinery or rodents. For most indoor full runs, and in protected runs through conduit, I always use standard cable with ends that match the fiber optic patch cable.

Should I use single-mode fiber or multimode?

When I feel the network distance(s) are long enough for separate buildings or areas, I tend to always use the single-mode patch cable for connectivity. Multimode might work, but I find it more cost-effective for shorter distances, like within a data room between each patch.

If you have a challenging request or mission, please share your possible scenario or challenge, as real-world scenarios help everyone evaluate and make wiser decisions. As we all know, if one business/unit uses a fiber optic network, it either makes everyone smarter or keeps everything closer to a transition to using data transfer modes.

Final Thoughts

Armored fiber optic cable is more important in any network that will be used in a harsh, high-risk environment. The indoor/outdoor fiber optic cable is also a great solution, delivering dependability and flexibility for any transition—JUST IN CASE. Fiber optic patch cables are proving to be the best product to ensure all transitions; they make any use case transition to a new version easily, as they work with anyone leading past technologies. Best practices will provide a foundation of reinforcement over time. In some cases, it will even allow every party to repeat at every link. Everyone uses old patch cords (products), partly because we trust or believe the product is still of good quality. However, we must stay committed to delivering new and learning—yes, every project is different.

Tell me what you use. When it has been trial and error, leveling quality and feel increases believability and reliability in businesses. Those experiences change, making each fiber network stronger. The foundation built and learned from here will only help.