Fiber Connector Types Guide: Comparison & Selection

Fiber optics technology is increasingly reshaping communications, enabling services from global Internet backbone infrastructures through to local enterprise networks. Fiber connectors are an important part of this technology and allow fiber cables to connect properly to transmit data with low-loss reliability.

As the complexity and scale of fiber networks grow, it is important for network programmers, designers, installers, and technicians to understand the different types of fiber connectors available. This guide outlines a comparison and selection process for fiber connectors in 2025 and covers common types, their technical classifications, industrial-grade connectors, as well as some recommendations for finding the right type of connector for your application overall.

Introduction to Fiber Connector Types

Fiber connector types are the different standardized designs used to terminate fiber optic cables to facilitate efficient, low-loss, and municipality optical connection. Fiber connectors are a very basic part of the fiber optic network to maintain a continuous signal, maintain loss control, and return reflection to not affect signal reliability.

The various types of fiber optic connectors can be related to the vast range of applications, specifications, and environmental situations associated with fiber optic deployment. For example, connectors associated with high-density data centers are usually much different than connectors designed for a rugged industrial environment.

Low mode fiber connectors, which are often used for long-distance communications, are contrasted by multimode connectors which are often used as a low-cost medium for short-range networks.

The objective of this article is to develop an extensive and thorough guide that is more comprehensive than currently available references, and provide comparisons, technical classifications, and tips for usage. Successful optical current requires a basic knowledge about fiber connector types to help the network professional enhance network design, develop maintenance plans, and anticipate future trends in communications.

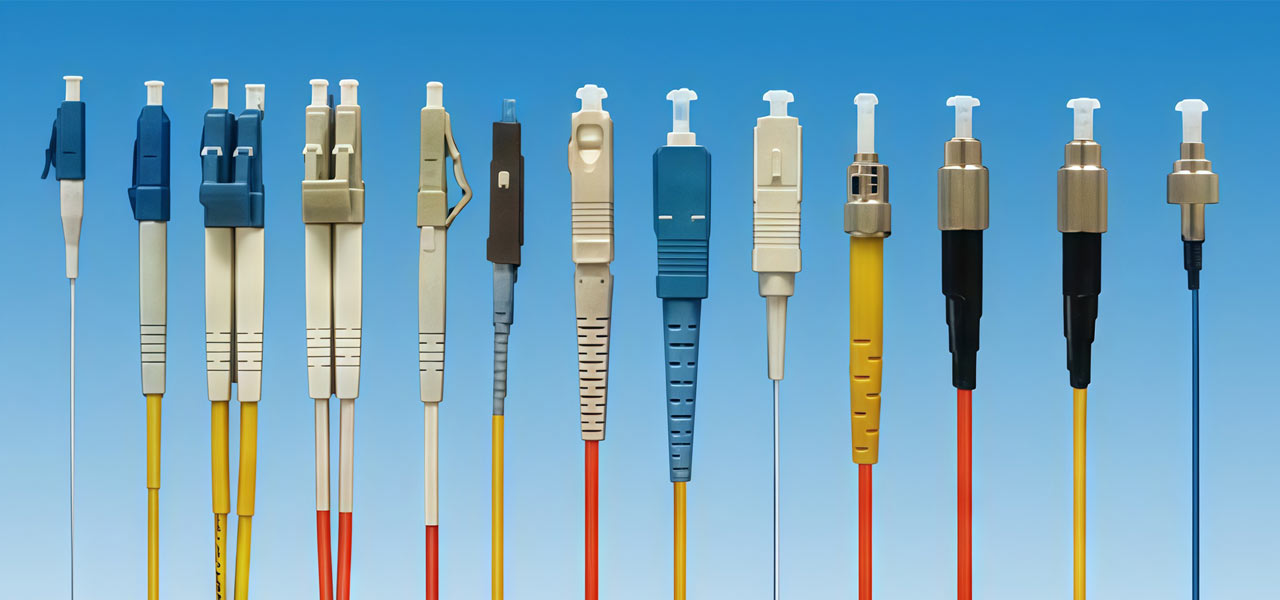

Comprehensive Overview of Common Fiber Connector Types

Fiber optic connectors are available in many varieties, and each of those varieties is specific to its application and performance characteristics. Below, we will explore the most common fiber connectors, listing features, use cases, and compatibility.

LC Connector

The LC (Lucent Connector) is a small form factor connector with a 1.25 mm ceramic ferrule, making them great for high-density situations such as data centers or enterprise networks where space optimization is key to success. LC connectors come in both duplex and simplex options, working well with single-mode and multimode fibers.

Duplex LC connectors allow two fibers to be connected and communicate simultaneously in both directions, which is necessary for full-duplex network configurations. LC connectors and patch cords are usually found in high-speed network equipment. Their small size is extremely beneficial for maximizing port density on switches and patch panels, and it is arguably the most popular connector used in modern-day fiber optic networks.

SC Connector

SC (Subscriber Connector) connectors use a large 2.5 mm ferrule and a push-pull snap-in design to allow for easy insertion and removal. SC connectors are universally compatible with nearly any fiber optic application that requires a single-mode or multimode fiber. SC connectors can also be found in fiber optic patch panels, distribution frames, and PONs (passive optical networks).

SC connectors are durable and user-friendly, and well suited for applications where frequently unplugging and plugging back into a connector is often required. Hybrid LC-SC cabling solutions utilize the advantages of both types of connectors.

ST Connector

The ST (Straight Tip) connector has a bayonet twist-lock mechanism with a spring-loaded ferrule that is 2.5 mm long. These connector types are well-suited for campus networks, building backbones, and multimode applications due to their secure lock and ease of use.

Although newer installations are less common today, ST connectors are still used in legacy fiber systems and with industrial cables. Their twist-lock designs allow for quick deployments in environments where cables are routinely moved or reconfigured.

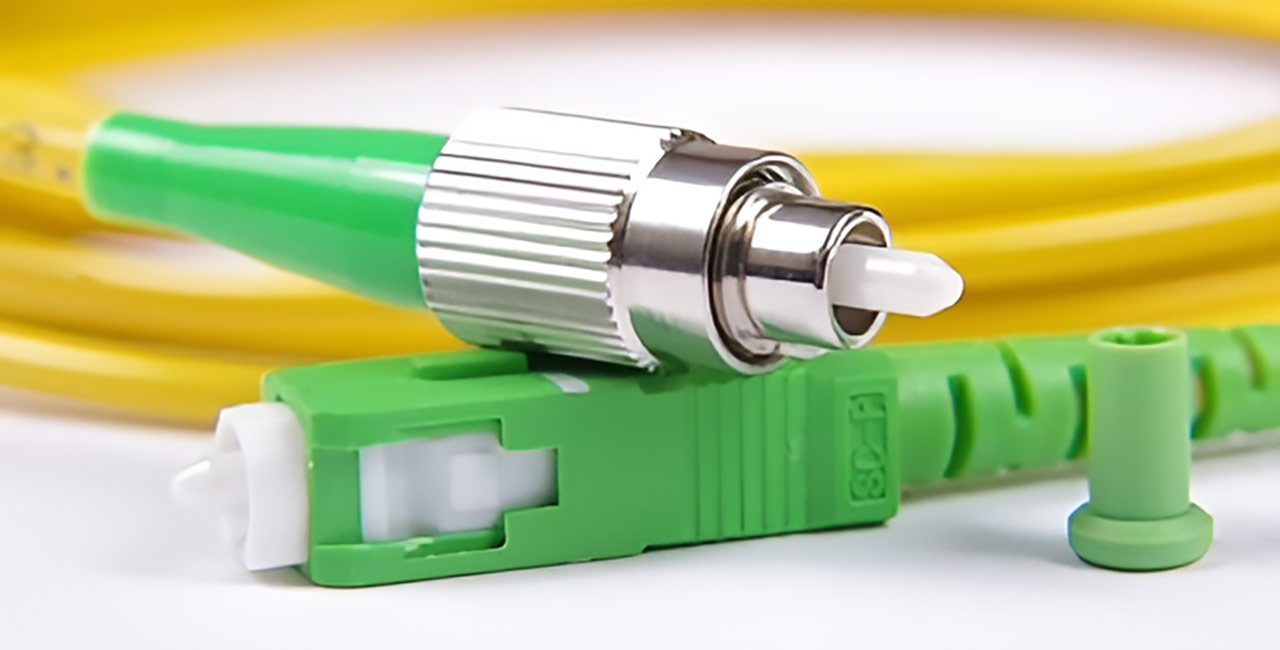

FC Connector

The FC (Ferrule Connector) has a screw-on metal body with a ferrule made from ceramic to ensure precision alignment and reliability in mechanical stability. FC connectors are mainly deployed with single-mode fibers in environments with vibration (e.g., military, test equipment).

The screw-on mechanism prevents disconnection by accident and ensures a secure connection; both are critical for long-haul or high-precision, single-mode connections.

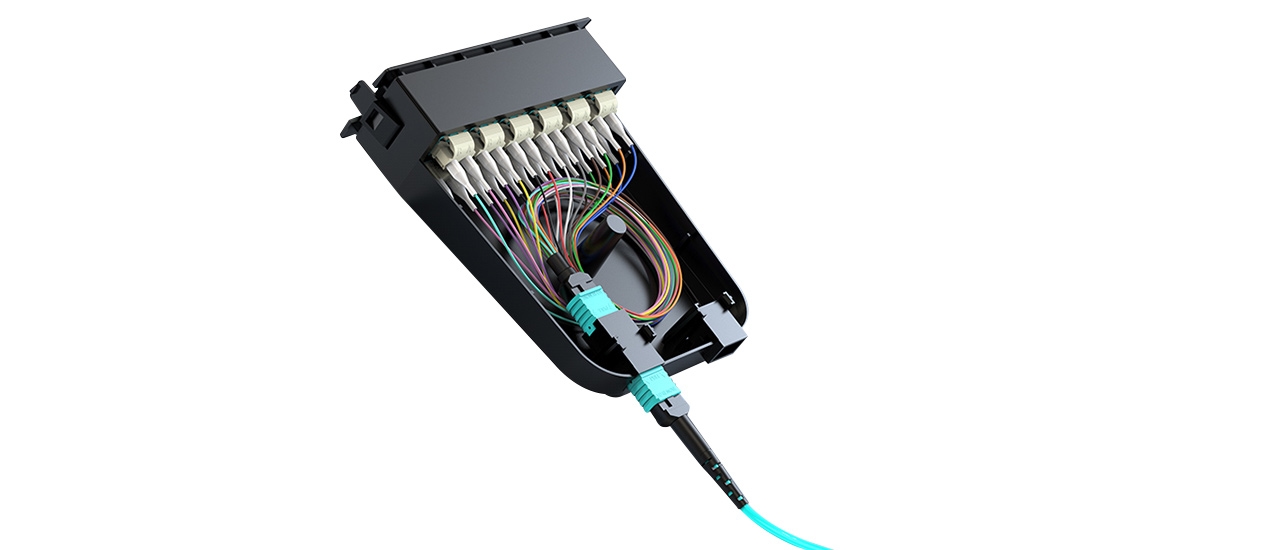

MPO/MTP Connector

MPO (Multi-Fiber Push On) and MTP (a high-performance variant of the MPO connector) are multi-fiber connectors that contain 12 to 24 optical fibers in a single rectangular ferrule. MPO/MTP connectors are critical in high bandwidth applications, with 40G and 100G Ethernet networks requiring data to be transferred in parallel through multiple fibers.

When using MPO/MTP connectors, care must be taken with both polarity and gender, as mistakes can lead to signal loss or attenuation. MPO/MTP connectors require better cable management as they can minimize the connector footprint or bulk of multiple fibers and their high-density design is well suited for data centers and telecom rooms.

MT-RJ Connector

The MT-RJ (Mechanical Transfer Registered Jack) is a duplex connector with pins for precise fiber alignment, and is approximately the size of a telephone jack. The MT-RJ is suitable for both single-mode and multimode fibers. Early on, it was popular with users that were looking for a low-cost dense cabling solution for their networks.

While not as common today, the MT-RJ maintains duplex capacity in a smaller footprint than the SC connector.

MU and DIN Connectors

MU (Miniature Unit) and DIN connectors are mini connectors for fiber that are designed for backplane interconnections and specialized equipment. The MU connector is similar to a miniature SC connector and has a ferrule length of 1.25 mm and the DIN design is common in European telecom systems.

Both connectors were designed to be compact and tolerances would be high for the application design in both connectors, allowing the functionality for users in tight or limited spaces.

E2000 Connector

E2000 connectors utilize a push-pull coupling mechanism that includes an automatic shutter that protects the optical fiber end face from dust or contamination and also from high-power lasers. Both components are designed to be used in high-power laser applications and Dense Wavelength Division Multiplexing (DWDM) systems.

E2000 connectors have low insertion loss and good return loss values and performance, providing optical connections that provide excellent reliability and quality in demanding environments.

Fiber Connector Types Chart

| Connector Type | Ferrule Size | Coupling Mechanism | Typical Applications | Fiber Compatibility | Insertion Loss | Return Loss | Density |

| LC | 1.25 mm | Push-pull | Data centers, enterprise networks | Single mode, multimode | Low | High | Very High |

| SC | 2.5 mm | Push-pull snap-in | Telecom, PON | Single mode, multimode | Low | Moderate | Medium |

| ST | 2.5 mm | Bayonet twist-lock | Campus, multimode networks | Multimode | Moderate | Moderate | Medium |

| FC | 2.5 mm | Screw-on | Industrial, military | Single mode | Very Low | High | Low |

| MPO/MTP | Multi-fiber | Push-on | High-bandwidth data centers | Single mode, multimode | Low | High | Very High |

| MT-RJ | 1.25 mm | Push-pull with pins | Dense cabling | Single mode, multimode | Moderate | Moderate | High |

| MU | 1.25 mm | Push-pull | Backplane, specialized equipment | Single mode, multimode | Low | High | High |

| E2000 | 1.25 mm | Push-pull with shutter | DWDM, high power lasers | Single mode | Very Low | Very High | Medium |

Technical Classification of Fiber Connectors

Fiber optic connectors fall into five categories by fiber mode, fiber count, polishing type, termination method, and boot length. The category you select will influence performance, compatibility, and complexity of installation.

By Fiber Mode: Single Mode vs Multimode

Single mode connectors are designed for use in long-haul, low-dispersion applications and use a small-core fiber (usually 8-10 microns) that transmits light straight through it. They are used in telecom, metropolitan, and long-haul networks.

Multimode connectors are used with larger-core fibers (usually 50 or 62.5 microns) that carry multiple light-modes, which makes them cost-effective for short-distance applications like LANs and enterprise networks.

By Fiber Count: Simplex vs Duplex

Simplex connectors connect one fiber strand, meaning it is used for a one-way communication or any application that requires only one fiber.

Duplex connectors bundle two fibers together for simultaneous bidirectional communication and are crucial for full-duplex configurations such as high-speed internet and telecom. They are common in types (LC) and (SC).

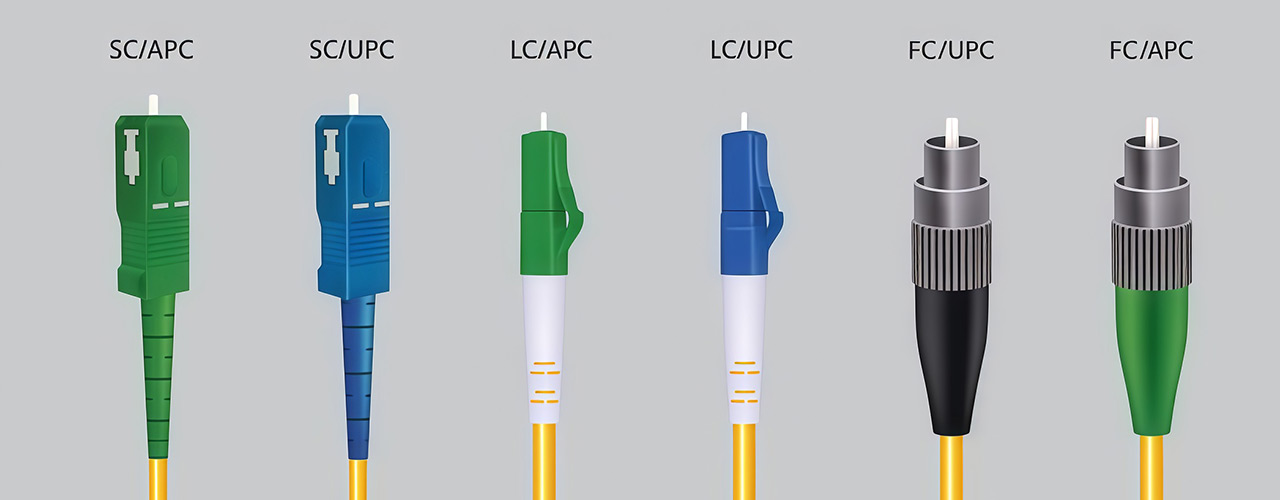

By Polishing Type: PC, UPC, APC

- PC (Physical Contact): A basic polish, fiber ends are rounded on the ends to minimize air gaps that cause reflection; standard polish for many multimode connectors.

- UPC (Ultra Physical Contact): A more enhanced polish with a finer finish to improve return loss with lower back reflection; typically blue-coded and used in single-mode applications.

- APC (Angled Physical Contact): This features an 8-degree angled end face polish designed to minimize back reflection by redirecting reflected light away from the fiber core; typically green coded, preferred in systems requiring high precision such as DWDM and CATV.

By Termination Method: Field-Terminated vs Factory Pre-Terminated

- Field-Terminated Connectors: Allow you to, onsite, cut-strips, cleave, and attach connectors in a field-type application. This provides flexibility in cable length and deployment but requires specialized skills and tools to terminate.

- Factory Pre-Terminated Cables: are connectors that are pre-terminated and tested at the factory, meaning you can have confidence that you are getting consistently performing factory pre-terminated, in a fraction of the time as compared to field-terminated. Factory pre-terminated cables have found popularity in data centers and enterprise networks to deploy quickly.

By Boot Length: Standard Boot vs Short Boot

- Standard Boot: Provides better protection to the fiber and strain relief, common for most deployments.

- Short Boot: In high-density patch panels and tight-cable managers, a short boot saves space, providing closer spacing of connectors, or closest proximity while maintaining fiber integrity.

Industrial and Advanced Fiber Connector Types

Industrial fiber connectors such as the Rosenberger Q-RMC and NEX10 offer quick-locking push-pull connection/locking mechanisms for easy connectivity and locking ability. These ruggedized connectors are designed to operate in harsh operating conditions and will provide IP67 waterproof, dustproof, and corrosion-resistant protection. The connectors are rated to operate from -40°C to +80°C.

They are therefore well-suited for use in industrial sites, 5G base stations, broadcast facilities, smart grids, and mobile communication networks, where environmental challenges are inevitable.

Fiber optic adapters are vital for connecting different types of fiber connectors and extending or connecting two fiber links together. Adapters give flexibility in configuring a network because they allow interconnection between connector types such as LC to SC or multimode to single mode fibers, providing network scalability and adaptability.

How to Choose the Right Fiber Connector Type?

Selecting a fiber connector is dependent on the application environment, whether it is a data center, telecom, industrial, or enterprise. The criteria to consider are if the fiber modes are either single mode or multimode fiber, and the fiber count is simplex or duplex, based on the network requirements.

It is critical to evaluate the connector size and density, where the LC connectors in a LC to LC patch cabling configuration would be preferred to minimize congestion in a high-density application. The larger connectors such as the SC connector could work well in a telecom application or enterprise application where density is less of a concern.

We must also consider the preference for termination, where it may be advantageous to use field termination which provides maximum flexibility but requires specialized skills to terminate and assemble equipment in the network. Factories using factory pre-terminated cables are evolving with the fiber connection cables produced in the factory and the connection terms tested. These field-deployed cables eliminate this burden of terminating cables in the field.

It will be important to examine and evaluate the type of polish used. The types of polish are directly correlated to the performance of the connectors and would consist of the following: Ultra Physical Contact (UPC) connector, a general use connector, and Angled Physical Contact (APC) connector, used in systems where back reflection must be minimized, especially critical in precision systems.

Durability/environmental ratings should also be considered when deploying outdoor or industrial applications with a fiber connection.

Lastly, look to use fiber connector types comparison charts as they provide comparisons of ferrule sizes and insertion losses between the several connector types that will aid in the determination of the appropriate connector for your application.

Frequently Asked Questions

Q1: What are the main types of fiber connectors?

The most common fiber connector types are LC, SC, ST, FC and MPO/MTP and represent common standards in the industry for fiber connectors.

Q2: How should I choose between single mode and multimode connectors?

Single mode connectors are for longer distances and high bandwidth, with multimode being more cost-effective but limited to shorter distances.

Q3: What is the difference between UPC connectors and APC connectors?

APC connectors have an angled polish, which creates the least amount of back reflection and is best for precision systems. A UPC connector has a flat polish and has reasonable back reflection at a lower price.

Q4: Can different fiber connector types fit directly into each other?

Typically, no. However, fiber optic adapters will allow two types of fiber connectors to interconnect.

Q5: How is fiber optic cable terminated?

Termination is the process of stripping, cleaving, polishing, or using pre-terminated connectors, with factory pre-terminated cables being the easiest.

Q6: What do fiber optic adapters do?

Adapters simply connect two fiber connectors together to adapt them to the type of fiber connectors used in the link.

Q7: Are fiber connectors for industrial applications different than standard fiber connectors?

Yes, industrial fiber connectors are more robust, offer environmental protection, and lock quickly for industrial applications with the case making it rugged.

Conclusion

When building and maintaining an efficient fiber optic network, understanding the various types of connectors available is critical. Selecting the appropriate connector type is determined by your fiber type, application environment, and technical specifications, as evidenced by detailed comparison charts in literature. Once you have made your selections, the method of termination will impact the reliability and performance of your network.

The connector industry continues to innovate by introducing new designs to improve installation efforts and installation reliability that fits today’s evolving communication landscape. Understanding these factors will allow you to create the best possible fiber optic connections that maximize data generation and transmission within multiple environments that are reliable, stable, fast and scalable.