Copper SFP vs Fiber SFP Modules: The Ultimate Guide to Making the Best Choice

When deciding between a copper SFP and a fiber SFP module, it can be a daunting task, particularly given the considerable impact on network performance and availability of each device. Each module will facilitate a unique set of advantages with respect to speed, distance, and price. Understanding what these trade-offs are will help inform better decisions when rolling out faster, more reliable connections, particularly in fiber. By looking at some important technical factors and other practical considerations, you will be able to determine which is most suitable for your network, to ensure an informed investment in high-speed, scalable infrastructure.

What Are the Fundamental Differences Between Copper SFP and Fiber SFP?

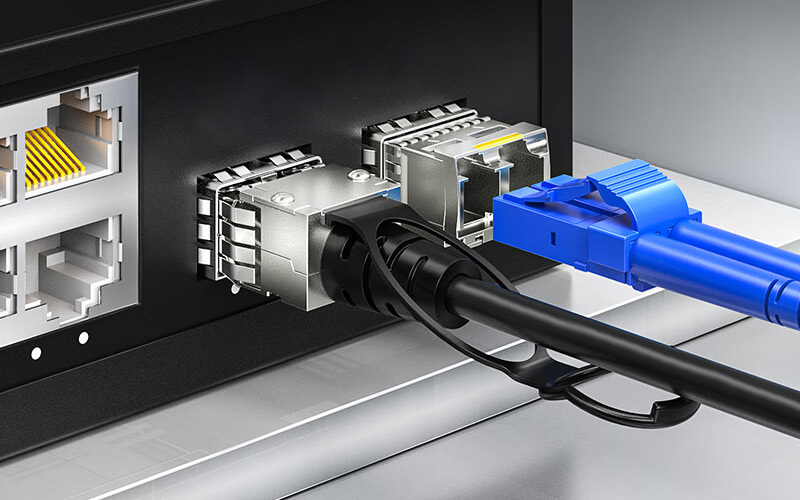

Copper and fiber SFP modules differ primarily in the way they transmit data signals. Copper SFP modules transmit electrical signals over twisted-pair copper cable, just like sound can travel through a wire. The electrical transmission is subject to limitations because of the quality of the wire and its susceptibility to outside electromagnetic interference, which can degrade the signal. Fiber SFP, on the other hand, uses light pulses to transmit data across fiber optic cable, similar to flashing a flashlight through a clear glass tube.

Because this transmission is optical in nature, fiber SFP modules have higher resistance to most electrical noise and will maintain signal strength over longer distances. Since copper cables carry electrical signals, they tend to have higher latency and bandwidth limitations than fiber optic. Copper SFP modules are usually best for shorter distances since they are susceptible to signal degradation and interference. Fiber SFP modules have the unique ability to reduce latency and maintain higher bandwidth, especially within longer, extended networks. Fiber optics do not suffer from electromagnetic interference and provide more reliable performance in situations where there is a lot of electrical equipment.

In summary:

- Copper SFP modules carry electrical signals over copper cables, which tend to be more susceptible to interference and limited distance.

- Fiber SFP modules carry signals via light using fiber optic cables and are, therefore, better for longer distances and less latency.

- Copper cables typically cost less, but fiber optics take advantage of scale and do better in noise interference.

Understanding the difference in these transmission types can help you understand why copper SFP and fiber SFP will serve different purposes in the design of your network around cost, distance, and performance.

Why Is Copper SFP the Preferred Solution for Short-Distance Links?

The copper SFP module, especially the 10G copper SFP, is an excellent solution in scenarios where the network link is a short distance. The advantages of copper over fiber optics include lower cost, easy installation, and lower latency. Copper’s ability to deliver an electrical signal directly to the device means data can be transmitted faster over short distances and with less installation complexity.

The 10G copper SFP is ideal for deployments in close proximity to one another; for example, between network devices in a data center rack. The 10G copper SFP keeps wiring within the network neat and eliminates costly expenditures on fiber optic cabling and labor. In addition, links to and from a server to a switch and the 10G copper SFP’s port to the network will be simple plug-and-play devices, again eliminating downtime from upgrades, maintenance, and hardware issues.

HIGH-LEVEL SFP AND CABLE ADVANTAGES:

Cost: Comparatively, copper cables and modules are less expensive than those based on fiber optics.

Easy Deployment: Since RJ-45 connections are fairly standard, the ease of connectivity means faster deployment, connectivity, and maintenance when swapping out modules or if the devices need to be reset.

Latency: Electricity virtually travels instantly over short distances.

Organization: Cost decisions and simplicity are typically at the forefront for using copper; however, this is all enhanced as the copper SFP is all about practical ports, switches, and modules for short distances and with fast link speed to enhance high-speed data transfer within a restricted, constrained network device environment.

How Does Fiber SFP Enable Long-Distance Transmission and Future Scalability?

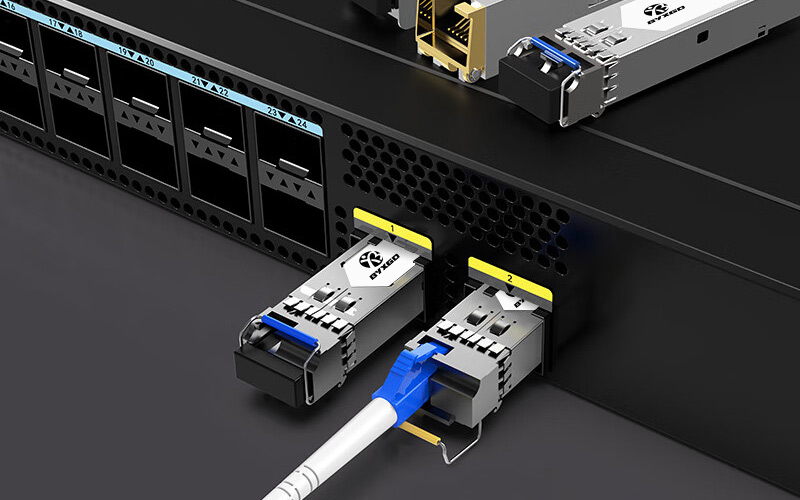

Fiber SFP modules provide unprecedented long-distance data transmission unavailable with traditional copper cables. Fiber SFP modules send data as light pulses through fiber optic cables, which eliminates the electrical interference caused by copper cables. Fiber is superior in terms of distance in crowded areas and has great signal clarity or quality. SFP modules travel for several kilometers without any measurable loss of signal strength, quite unlike the typical hundred-meter range with copper cables.

The extended range of fiber SFP modules is beneficial for large campus or enterprise networks, connections between data centers in separate buildings, and connecting across metropolitan areas. Another benefit is the flexibility of fiber optic SFP modules. Fiber SFP modules allow changes or upgrades to the network without the considerable effort required to pull or rerun all of the cables in a facility or building. Fiber optic SFP modules allow for upgraded equipment or changes to the network layout without inconvenience.

Scalability is also a significant advantage! Fiber SFP is ready for the bandwidth demands and evolving standards of tomorrow, so you always ensure a future-proof network! Fiber optics have low attenuation and are not affected by electromagnetic noise, which means the integrity of the signal is kept as the data rates increase. This reliability makes fiber optic SFP the best choice for infrastructure that may grow in the future.

To summarize the benefits of fiber SFP:

- Long distance reach far beyond the limitations of copper

- Electromagnetic interference is no longer a concern

- Bandwidth is scalable to fit your evolving needs

With fiber SFP, you can rest assured that your network is built to last, accommodates your future needs, and gets data to the destination without interference.

What Are the Performance Differences: Latency, Signal Integrity, and Error Rates?

Copper SFP and fiber SFP modules vary significantly with respect to latency, signal integrity, and error rates. Copper SFP (on the left) modules transmit an electrical signal over copper cables. These copper cables introduce some delay due to resistance and electromagnetic interference, which can create some signal attenuation, especially over longer distances, resulting in additional errors. Fiber SFP modules (on the right) use light to transmit data, which is much faster and without delay or interference.

Copper SFP’s re-shown distance benefit, as it affects latency, is important when latency is paramount. For many real-time applications or high-frequency trading that we interface with, copper SFP stands to gain from its direct electrical connection advantage. However, for throughput-based services needing reach, fiber SFP is far superior in signal fidelity. Light signals are able to travel several kilometers with just a little attenuation, ensuring their error rates stay low, even when still near optoelectronic components.

This holds true even when optical signals take a route through semi-structured, multi-tenant, and any affiliated buildings or facilities. The key differences in performance are:

- Latency: Copper SFP networks produce a bit more delay with longer cables than fiber-reinforced applications; fiber SFP gives you almost instantaneous communication.

- Signal fidelity: Fiber SFP doesn’t take on interference as easily as copper, which nearly always results in application failure.

- Error rates: Copper coax cables are more faulty over greater distances than fiber coax cables in long-distance applications.

Now, most everyone knows that fiber and copper suggest very different applications. Copper SFP makes the most sense for shorter, lower-latency, low-error performance, while fiber SFP is best suited for applications where higher performance is needed, depending on the requirements of the application itself, such as both bandwidth and capacity, as well as distance and fidelity.

Why Are Power Consumption and Thermal Management Critical Factors?

Variable Power and Temperature Affairs play an important role in determining the choice of network module, especially in high-density data center environments. While the 10G copper SFP and SFP copper module typically consume more power than a corresponding fiber module, they do so because they rely on electrical signals which generate heat, both through the cable, as in resistance, and using the copper modules’ internal circuitry. Any extra heat generated requires extra energy and resources to maintain an acceptable temperature threshold in the data center, ultimately costing money.

Fiber SFP modules consume less power than their copper counterparts, because fiber transmits data using light, and fibers produce little to no heat. Therefore, fiber modules help facilitate a cooler environment, ultimately reducing the expense and complexity of cooling infrastructure.

In summary:

- Copper SFPs use more power than they should because of energy losses from electrical transmission.

- Copper’s higher heat output requires a better and more powerful cooling solution.

- Higher cooling needs will result in more cost to run the data center.

- Efficient thermal design is important for operational costs when many SFP copper modules operate at the same time. Selecting copper modules with lower power consumption can reduce costs and improve operational reliability due to overheating potential.

How to Choose Between Copper SFP and Fiber SFP: A Practical Framework

When deciding whether to use copper SFP or fiber SFP, you need to evaluate the key considerations of throughput, latency, power consumption, reach, and cost. Each type of SFP module has features that will take advantage of specific scenarios, so laying out the comparison of copper SFP next to fiber SFP will help clarify the ultimate product for your application.

Throughput and Latency: Copper SFP and fiber SFP can obtain high data rates. For example, 10G copper SFP modules perform very well during high-throughput situations. Copper SFP performs well for short distances with negligible latency. Fiber SFP is better suited to maintaining low latency and stable throughput over longer link distances.

Power usage and heat: Copper SFP inherently consumes more power than fiber SFP modules, which creates more heat and requires additional cooling. Fiber SFP modules have lower power consumption, which eases thermal management and provides lower energy costs compared to copper SFPs.

Reach: Copper SFP works well for links up to approximately 100 meters. Beyond that distance, degradation of the signal limits performance. On the other hand, fiber SFPs are ideal for longer distances of several kilometers, which would be useful in larger networks and for future expansion.

The cost: Copper SFP modules and copper cables may typically be cheaper on the upfront purchase; however, the greater durability and low maintenance of fiber SFP can offset the upfront cost over time and use.

Here’s a quick comparison:

| Feature | Copper SFP (Including 10G copper sfp) | Fiber SFP |

| Throughput | High at short distances | High over long distances |

| Latency | Low at short range | Consistently low |

| Power Consumption | Higher | Lower |

| Max Reach | Around 100 meters | Several kilometers |

| Initial Cost | Lower | Higher |

Taking deployment needs into account is important. For instance, short links that are sensitive to expense would utilize a copper SFP. Conversely, an environment that requires long-distance transmission and does not want to deal with interference would utilize a fiber SFP type. All of this needs to be taken into consideration for efficient network design and scalability.

What Lessons Does a Real-World Hybrid Deployment Offer?

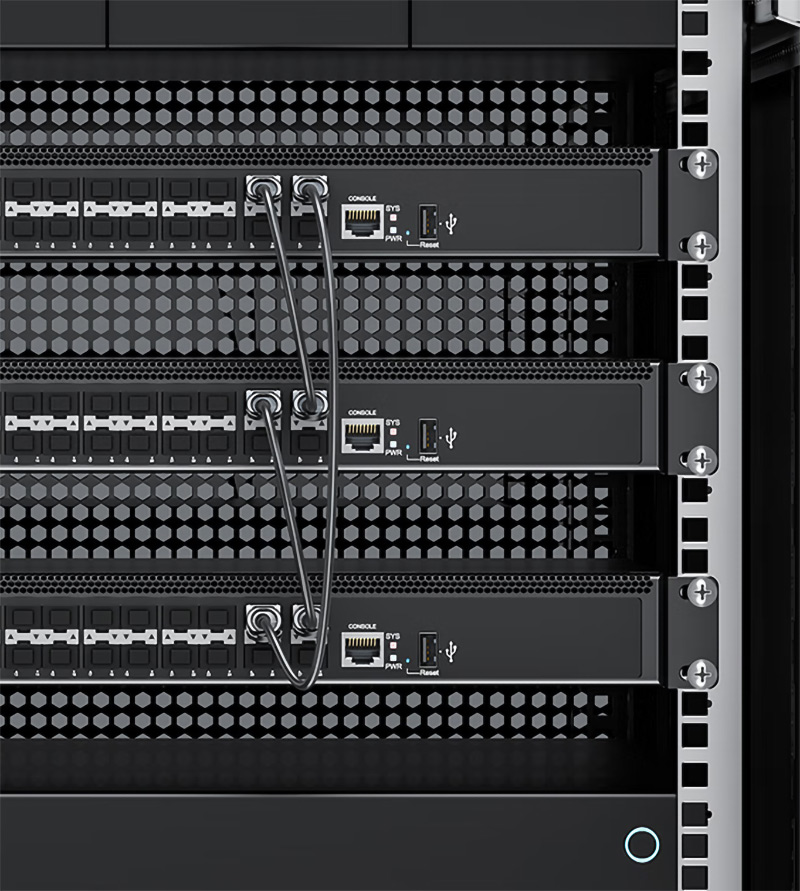

Insights from a real-world enterprise deployment incorporating both SFP copper modules and SFP fiber optic modules provide valuable insight into the balance of cost and performance. In a hybrid network deployment, the copper SFP module will handle your connected devices with short-distance links to servers with minimized cost and installation. Fiber SFP will be used to extend connectivity between your data centers or at least across buildings while maintaining low latency and signal integrity for longer distances.

This model creates an advantage from a cost-of-ownership perspective, using copper whenever possible to minimize cost and fiber whenever necessary to maximize performance. The results are measurable, and the performance effects include increased overall efficiency of the network by prioritizing traffic between fiber links to increase throughput. In addition, deploying copper SFP modules can minimize costs on short-distance linked devices without signal loss.

Hybrid deployment lessons learned include the following:

- Cost Effectiveness: The combination of modules increases network deployment uptime and minimizes server rack and switch installation costs.

- Performance Balance: Fiber modules add reliability over longer distances for connections between buildings, and copper can be used to minimize delay issues from a local connection to the copper SFP modules connected to the device, switch, or server rack.

- Network Flexibility: Hybrid deployments lead to device and network adaptation with accessible infrastructure changes.

The hybrid deployment approach utilizing both SFP copper modules and SFP fiber optic modules used by an enterprise assists in scalability and expenses, enabling the enterprise to create a resilient, efficient network architecture.

How Does Installation Complexity Influence Network Design and Costs?

The complexity of installation drives the design of the network and overall costs. Copper SFP modules usually use known RJ-45 connectors with twisted-pair cabling that can generally make cabling easy and reduce installation time. Fiber SFP modules require handling of delicate fiber optic cables with specific connectors that tend to entail additional installation skills in order not to damage the fiber optic cabling.

Fiber installations involve careful connector alignment and cleaning to maintain signal quality, adding to the time and labor costs. Maintenance for fiber SFP modules is also more demanding than copper SFP modules in that even the slightest bend in the fiber, as well as dirt, can degrade fiber performance. Copper SFP modules are generally more straightforward for maintenance and replacement and are less volatile to physical impact.

Furthermore, there are a few practical tips available to potentially minimize downtime:

- Use pre-terminated fiber cabling to minimize connector handling.

- Train personnel on fiber optic maintenance, as this is the first step to avoid common mistakes made during installation.

- Plan cabling layout to minimize physical inaction and make maintenance easier.

- Label cables when installing or repairing to speed troubleshooting or maintenance activity.

Finally, the choice between copper SFP and fiber SFP can impact not only performance but also the efficiency of installation procedures as well as the work burden on staff. Copper is great when quick installation is most important, while fiber is best in future-ready networks that can justify a higher upfront installation burden for long-term benefit.

What Are Best Practices for Compatibility and Long-Term Reliability?

To guarantee compatibility of SFP copper modules with SFP fiber optic modules, as well as reliability over time, careful selection of vendor and firmware is a critical step. Testing interoperability on a regular basis allows organizations to identify potential problems before major network failures occur due to components that don’t get along or older firmware running on their modules.

Additionally, having some sort of monitoring in place is essential for maintaining uptime. Proactive monitoring tools can track performance on each module or signal quality on each fiber and notify a technician before signal quality fails and causes a network issue. Furthermore, regularly scheduled preventive maintenance, such as cleaning the fiber connectors or checking every module’s updated/released firmware, can lengthen the lifespan of SFP copper modules and SFP fiber optic modules and provide continued consistent performance.

Recommendations for maintaining quality SFP copper modules and SFP fiber optic modules:

- Acquire modules from established vendors that are known for compatibility.

- After upgrades or new modules, schedule the interoperability testing.

- Have continuous monitoring established to identify where performance drops before service fails.

- Schedule maintenance for cables and modules in advance.

These suggestions ensure that SFP copper modules and SFP fiber optic modules will provide long-lasting stability, effective management, and reduce unforeseen failures of service.

What Emerging Technologies Will Shape the Future of Copper and Fiber SFP?

Innovative technologies are expected to make advancements over time regarding 10G copper SFP and fiber SFP modules. We are already seeing newer and higher-speed copper standards that aim to go beyond 10G and provide various advantages. In addition to better data throughput, each of these upgraded copper modules will maintain the cost-effectiveness of using copper for short links. These technologies will help minimize the concerns colloquially known as “issues” regarding power usage and heat that many of us have encountered with copper SFP modules in the past.

On the fiber SFP side, “low-power” fiber optic modules are already being offered that enjoy improved operational efficiency with little, if any, compromise to distance or speed. These modules are perfect candidates for larger data centers and large-scale network environments. Advances in compact integrated optics have also minimized size and cost.

Both of these technologies are an important part of supporting 5G infrastructure and edge computing. Fiber SFP modules will allow for high capacity and very long-term use as an effective “5G backhaul.” The upgraded 10G copper SFP module will be geared to handle edge nodes with “fast” and “easy” connectivity to support “latency-sensitive” applications.

The most important trends we should expect are:

- Higher-speed copper SFP standards capable of expanding short-range capabilities.

- Energy-efficient fiber SFP modules that will eventually lower operational costs.

- 5G and edge computing will be integrated into more flexible architectures in networks.

These are foundational approaches to building faster networks and smarter networks that will scale to exploit future data requirements.

Conclusion

Opting between copper SFP and fiber SFP relies on a few important considerations. Distance plays a role—copper SFP works best for short-distance solutions, while fiber SFP works best for long-distance applications. Cost matters too—copper modules will usually have a lower acquisition cost, but fiber will be the better option if you expect to upscale.

Performance can vary depending on the application: while copper SFP falls short of throughput expectations when distance is a factor, low latency is achievable closer to the link, while fiber SFP can support upgraded throughput over long distances, without signal integrity loss or latency. Power consumption must also be factored into operational costs (for everyday use), while fiber SFP is generally more energy-efficient.

We suggest using a data-driven framework to assess throughput, latency, reach, and estimated costs when determining what option to choose; balancing copper SFP, fiber SFP, and 10G copper SFP options can help you make the best use of your budget while looking towards the future.

Reference Sources

- Wikipedia

Small Form-factor Pluggable (SFP)

This Wikipedia article details the SFP interface as a modular slot for fiber optic or copper transceivers, explaining their applications, standards, and form factors. - Sopto

What is Copper SFP Transceiver Module?

This page explains the copper SFP module, its features, differences from fiber SFP modules, usage scenarios, and cable requirements. - QSFPTEK

SFP meaning, Fiber SFP and Copper SFP Types

This resource covers classifications of SFP modules, describing copper SFP and fiber SFP types, connectors, transmission distances, and typical applications.