You are installing an Internet drop in the hall of a high‑rise building. Instead of using fusion tools and waiting for a specialist, you use the 3L Nut Type SC APC/UPC Quick Connector as a new way to wire. The compact connector is in your toolbox. To use it: put the tail nut on the fiber optic cable, strip back the outer jacket to expose the fiber optic strand, clean and cut the fiber end to an exact length, insert the fiber with a slight bend to maintain tension on the fiber, twist the nut to secure the fiber, then test the light signal. If the light signal passes, move on to the next drop.

In addition to FTTH applications, this connector can be used in Security Camera Networks, Smart Building systems, and will provide a solid connection every time. All screws and nuts will come with a factory test that confirms compliance with ISO telecom standards.

Why Choose 3L Nut Type SC APC/UPC Quick Connector

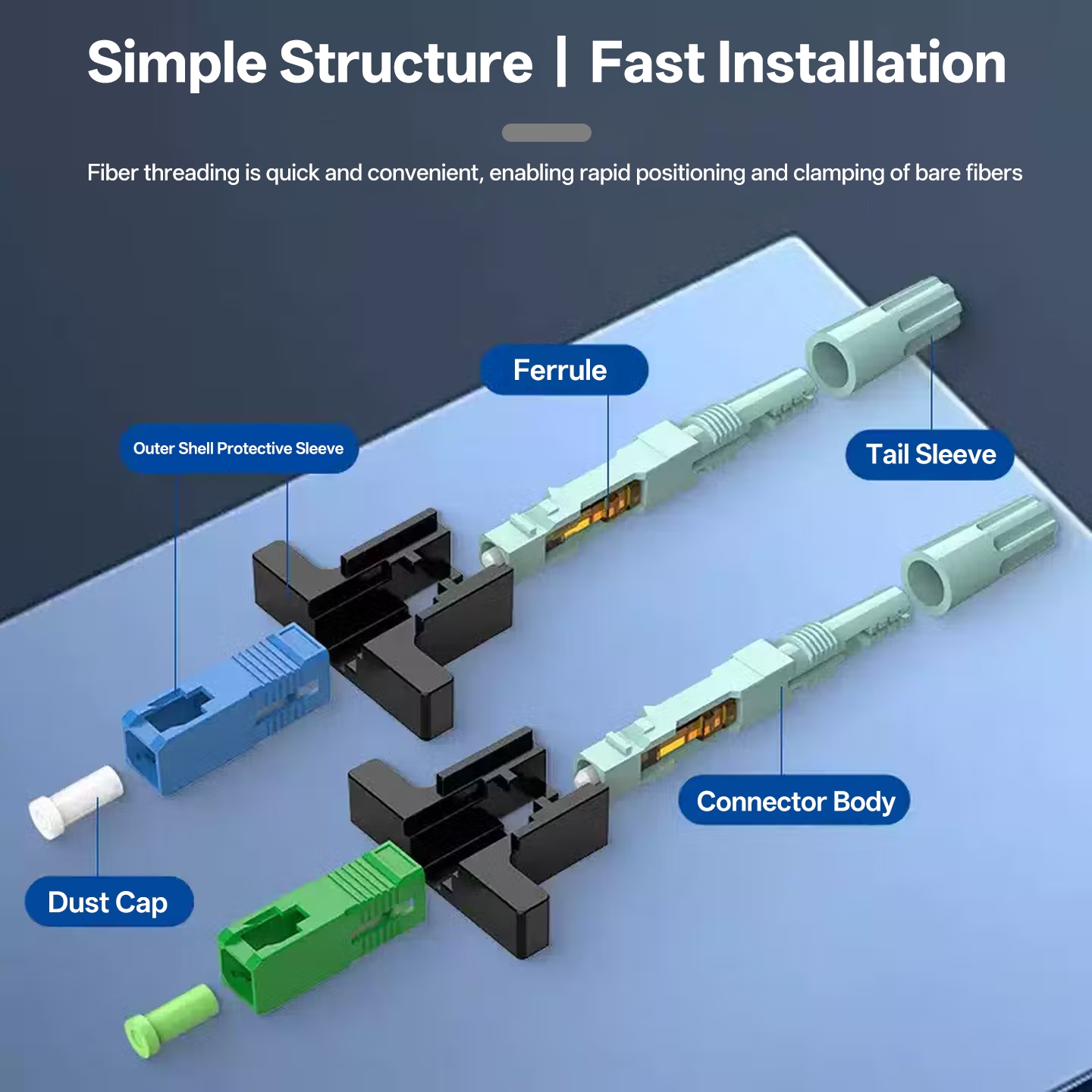

Fieldwork is defined by reliability; dropped signals or lost connections result in overtime hours and unhappy customers. The connector found within this product has been designed to address the above issues. The ceramic ferrule inside aligns the fibers within the connector perfectly, even after multiple reuses.

Technicians rely on this PEI shell to perform day after day. The areas where technicians must work are often confined, which can lead to tool drops and scratches on the wall. This material is designed to withstand these challenges and is highly resistant to both scratches and flames. Furthermore, it can withstand high impacts. Unlocking this material for reuse takes only seconds, with a maximum of 50 cycles before anything changes regarding performance.

Consider a service technician or crew that will install approximately 20 drops into various apartments in one day. The amount of time, equipment, and setup required to properly fuse cables with traditional methods would take a heavy machine and hours of preparation. Using this product, services can be completed within 90–120 seconds of first use following some initial practice. The bulk 100‑pack of this product will keep service operations running smoothly throughout the entire week.

Detailed Installation Process — 10-Step Quick Installation Guide

- Preparation: The tail nut is to be placed on the 2.0 x 3.0 mm drop cable.

- Stripping: Strip the outer jacket of the drop cable approximately 50 mm from the cable end.

- Gauging: The fiber should be placed within the provided length gauge, marking where to strip the coating off the fiber.

- Coating Removal: The coating must be stripped from the fiber (250 µm/900 µm) at the gauge mark.

- Cleaning: Using alcohol with a lint‑free cloth, clean the bare fiber of any contamination. ⚠️ Important: After proceeding with cleaving, do not touch the end face of the fiber. Doing so will increase the chance of contaminating the fiber.

- Cleaving: You must use a precision cleaving tool in order to obtain a flat 90° end face.

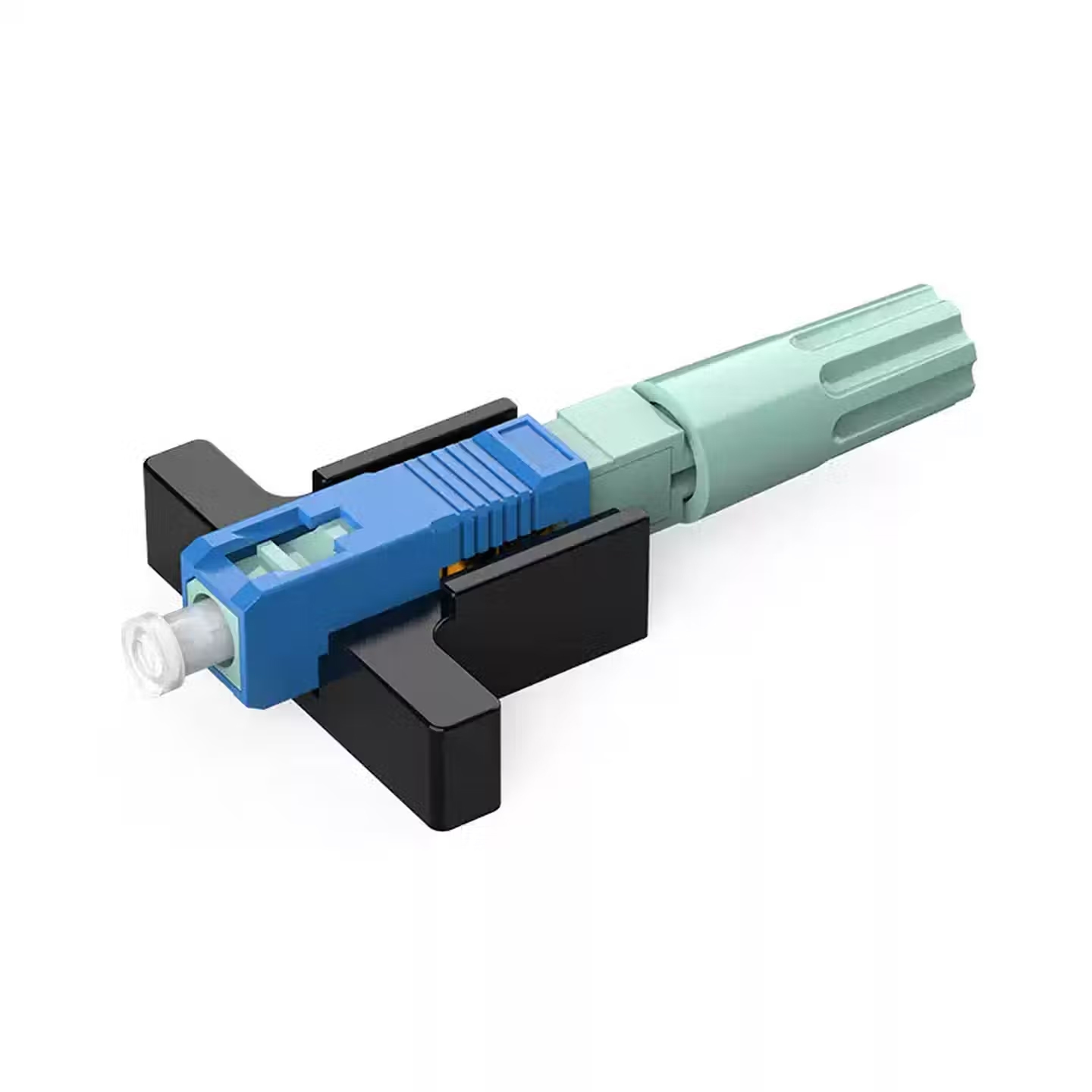

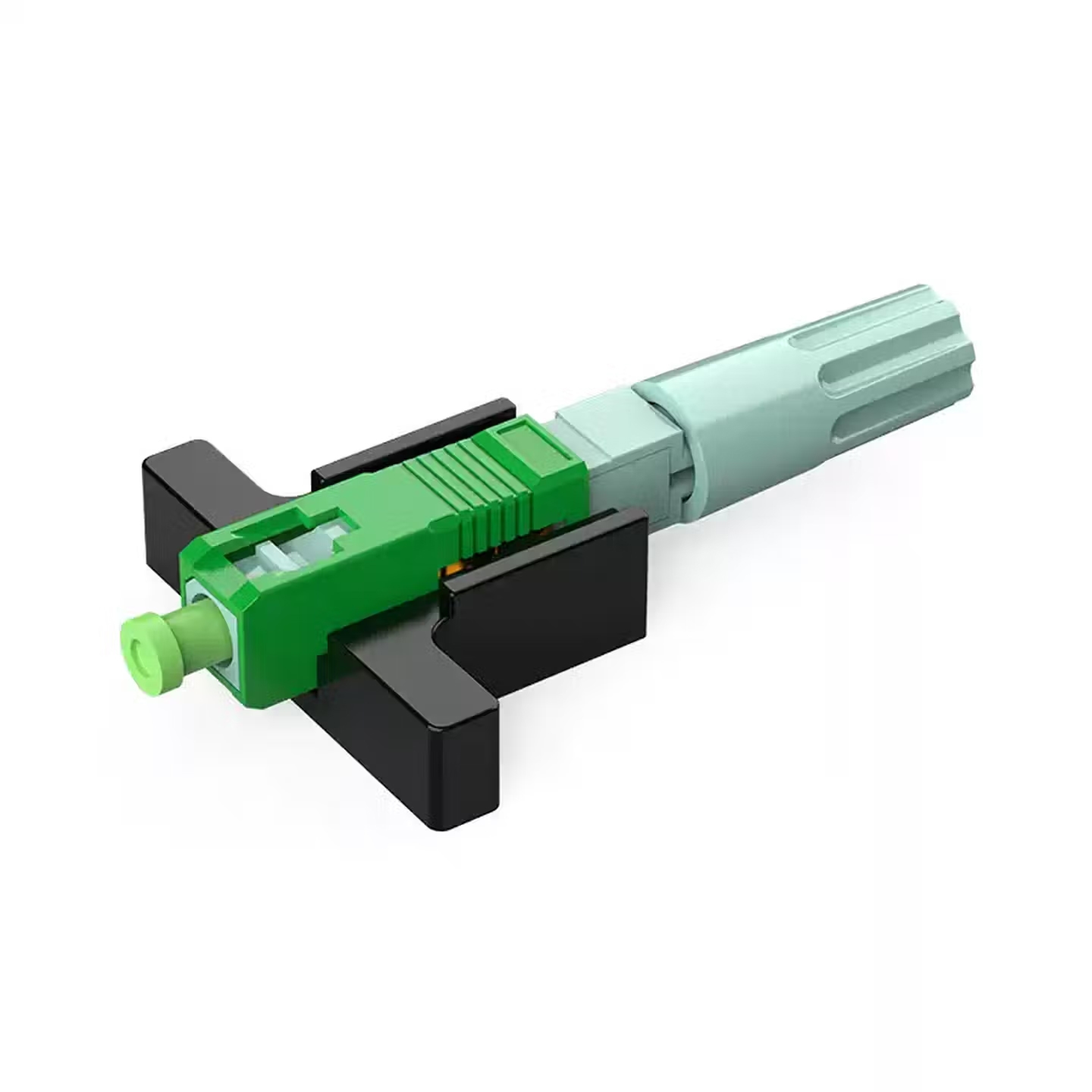

- Unlocking: The black shell must be slid to the “Open” (backward) position.

- Insertion: Insert the fiber into the black shell until you see a clean micro‑bend form. This indicates consistent contact.

- Locking: After inserting the fiber, the black shell must be slid to the forward position and tightened by hand.

- Final Check: Snap the dust cap onto the fully assembled unit and test using a light source.

Repeat these ten steps at least once to ensure that you can consistently complete the installation in under 2 minutes.

Reuse and Maintenance Guide

In the future, field connections will require replacement; this is taken into account with this design. To unlock the mechanism, push down on the black shell; to unscrew, turn the tail nut to the left (counter‑clockwise). Remove the fiber from the connector in a slow, even motion. If any residue remains inside the connector, clean out the channel.

The result of testing with 50 insertion losses shows a variation of less than 0.2 dB; if the fiber were to break while inside the connector, it would be necessary to replace the entire connector. Please do not force any components that have become damaged.

To maintain performance levels, please wipe the ends of connectors prior to mating them with a professional cleaner, store all connectors with the dust caps on, and always route all cables so that there are no sharp bends.

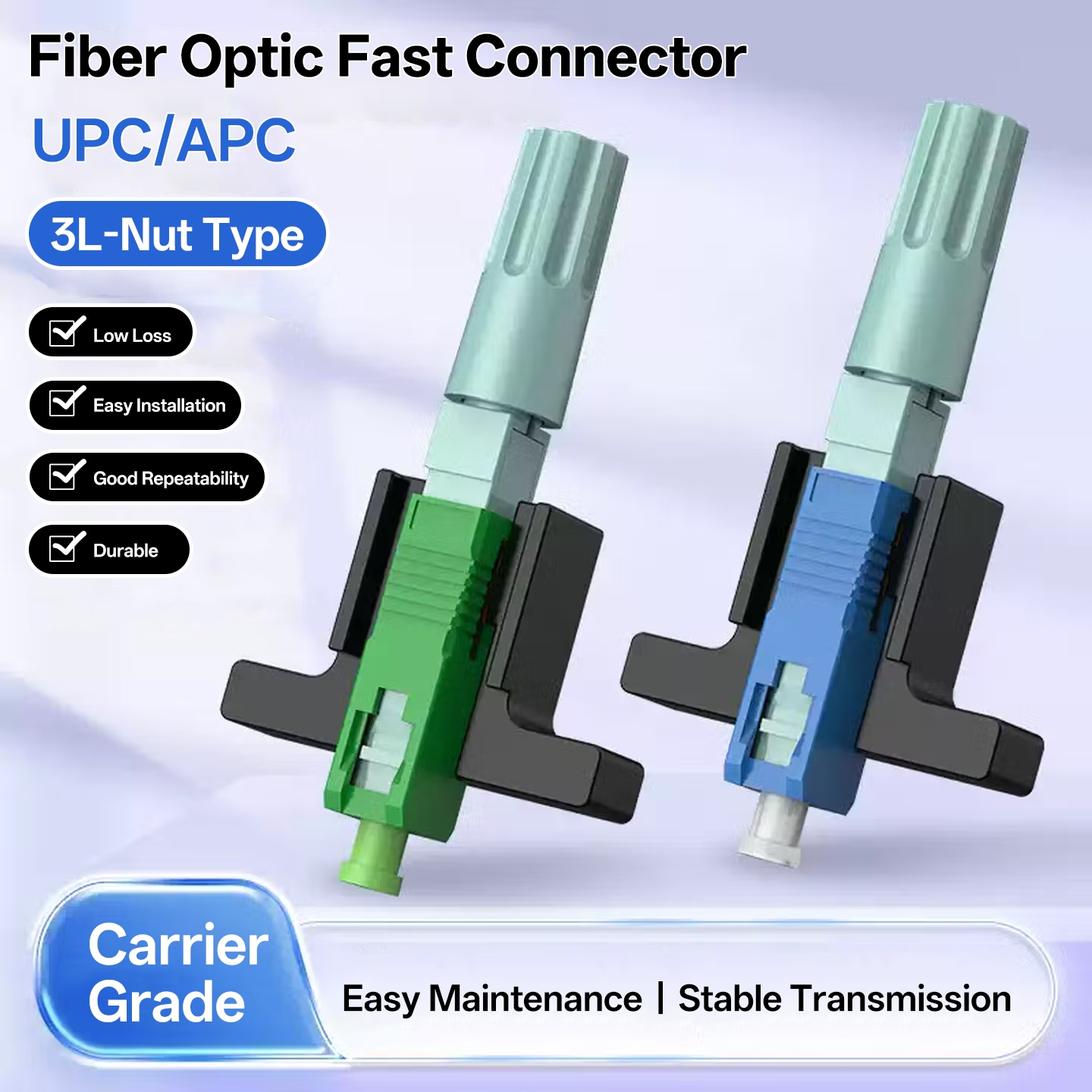

UPC vs APC Selection Guide

Network types dictate the type of polish used. UPC is the most commonly used polish type for traditional telecommunications applications—it has a precision physical contact (PC) polish and appears blue or white. Mobile carriers, Unicom, and other telecommunications providers have been using UPC connectors every day since the inception of their service. This connector has the least amount of reflection, which provides a stable flow of data.

APC is ideal for all types of video broadcasts. The 8‑degree angled green polishing of the APC connector greatly minimizes back reflections. Video transmission, CATV (Cable Television), and all other applications that are sensitive to reflections benefit greatly from the advantages of using an APC connector. You should choose based on what your individual network needs are.

Connector Type Summary

| Connector Type | Polish Angle | Typical Color | Primary Applications |

| SC‑UPC | Pre‑domed / PC | Blue/White | Telecom, mobile, data networks |

| SC‑APC | 8° Angled | Green | Broadcast, video, CATV systems |

Selection Guide

| Feature | 3L Nut Type | Gland Type |

| Locking Mechanism | Threaded screw‑nut locking | Flip‑cover or push‑latch lock |

| Best For | High‑tension, outdoor environments | Rapid indoor deployment & tight spaces |

| Tensile Strength | Superior (>50 N) | Reliable (>30 N) |

| Installation Speed | 90–120 sec | Excellent (~90 sec) |

| Reuse Cycle | 50+ times (Non‑destructive) | 50+ times (Snap‑lock mechanism) |

| Typical Use | Aerial drops, Building backbones | FTTH residential ONT, Indoor wall outlets |

Technical Specifications

| Parameter | Specification |

| Total Length | 58 mm |

| Compatible Cable | 2.0 × 3.0 mm Drop Cable |

| Ferrule Material | Ceramic |

| Insertion Loss | ≤0.3 dB (tested at 1310 nm & 1550 nm) |

| Return Loss | ≥50 dB (UPC), ≥55 dB (APC) |

| Operating Wavelength | 1200–1600 nm |

| Temperature Range | -40°C to +75°C |

| Bare Fiber Pull Strength | >5 N |

| Clad Fiber Pull Strength | >10 N |

| Overall Tension Resistance | >50 N |

| Assembly Reuse | >50 times |

| Mating Durability | 500 cycles |

| Mechanical Durability | IL variation ≤0.2 dB, RL ≤5 dB |

| V‑Groove Material | Ceramic |

| Back Cover Color | Black |

| Expected Lifespan | 500 cycles |

| Compliance Standards | Telecom Grade, IEC61754‑4 |

| Certifications | ISO, SGS, ROHS |

Ratings derive from pull tests, temperature cycling, and repeated matings. Field conditions remain well within these limits.

Common Applications

Home installation technicians place drops in units. Security installers run the wires for camera systems. Building engineers connect buildings to local networks. Broadcast engineers provide television feeds to studios. Smart factories use connected sensors. High‑speed rail projects need secure connectivity. Quick and durable connectors meet all these needs.

Troubleshooting Field Problems

Occasionally, batch installation may have higher loss than normal. Check that all pieces are measured with the length gauge. It will give you an exact coating length to use. Ensure the cutter blade is in good condition. Flat‑ended blades will produce a smooth mating surface, while angled‑blade cutting will increase losses. Clean the ends of all parts very thoroughly. Dust and oil contamination reduce signal quality. Maintain a slight curve internally in the connector. Too tight a curve will misalign the signal cores.

Clean and organized workspaces significantly decrease the chances of running into problems. Poor preparation is often responsible for most problems you will experience.

Package Contents

Whenever an order is placed, a single box is shipped with 100 of each SC‑UPC / APC 3L Nut Type connector. A visual quick‑start guide lists the steps needed to install. Each package will include a single precision‑length gauge to ensure proper lengths. Connectors are shipped in plastic bags inside individual protective boxes.

Regardless of whether a team’s work is done installing residential complexes or installing on a rail, the connections hold up, and the signals stay strong throughout all phases. These connectors help complete all projects on time and on budget.

Reviews

Clear filtersThere are no reviews yet.