10 Things You Should Know About Polarization Maintaining (PM) Fiber Splicers

What Is a Polarization Maintaining (PM) Fiber Splicer?

Polarization maintaining (PM) fibers are unique optical fibers that are manufactured specifically to retain the polarization state of light signals and are required for operation in fields such as sensors, modulators, and coherent communication (communication systems that require some form of phase or polarization relationship to encode and decode optical data). PM fibers work differently from normal singlemode (SM) fibers as standard SM fibers would not have the design or the ability to maintain the polarization state of light both during transmission and, most importantly, during signal splices into a network. PM fibers utilize several internal structures in the PM fibers, such as the introduction of stress rods, to create birefringence, which maintains the orientation of polarized light signals as they transmit through the fiber.

PM fiber fusion splicers function as a high precision splicing tool, specifically, PM fiber fusion splicers splice PM fibers together without disturbing or changing their polarization properties during the splice operation. PM fiber fusion splicers splice by aligning the two fiber cores and aligning the fiber’s polarization axes before the splicing operation continues. This differs from the normal single-mode fiber splicing method where the splicing operator aligns only the two cores without regard to maintaining the polarization axes of the polarizing light during the splice.

It is important for engineering professionals to understand how PM fiber splicers function and their unique operation method so they can build networks that operate at a high performance level, where polarization is important and sensitive to optical networks.

Polarization maintaining fiber fusion splicer displayed on a table, showing its design and control panel.

Structure and Characteristics of PM Optical Fiber

PM fibers are designed with interior stress components, such as stress rods, to provide birefringence, or differing indices of refraction for light traveling through the fiber in orthogonal axes. This birefringence and accompanying stress will stabilize the polarization of light as it travels through the PM fiber and will not degrade the signal.

Common PM fiber designs include Panda, Bow-Tie, and Elliptical fibers. Each of these fibers has an identifiable structure with unique design features to meet specific performance needs. For example, the Panda fiber incorporates two cylindrical-shaped stress rods that resemble panda eyes. Panda fibers demonstrate the best performance for polarization maintenance among PM fiber designs.

PM fibers are popular in high-performance optical systems for all applications where the preservation of polarization is of utmost importance (e.g., optical fiber sensors, optical modulators, and coherent communication networks).

How Do Fiber Fusion Splicers Work?

Fiber fusion splicing connects two optical fibers by accurately lining their cores up and using an electric arc to fuse them together. The result is a smooth, low-loss connection. However, PM fiber fusion splicers are specially designed to manage also the complexity of maintaining polarization.

Distinctive assets of PM splicing machines include rotary fiber holders that allow technicians to rotate the fibers to accurately align polarization axes. It is critical to ensure precise alignment of polarization axes because even slight rotational misalignment will degrade the polarization extinction ratio (PER) and increase splice loss.

In addition, PM fiber splicing machines come with advanced imaging on higher-end models and automation controls, which provide accuracy and repeatability to make high-quality splices for polarization-sensitive applications.

The Importance of Precise Alignment in PM Fiber Splicing

To maintain the polarization state while splicing depends heavily on precise core and polarization axis alignment. If the fibers are misaligned, the PER will drop considerably, creating a greater splice loss and degrading the signal.

PM fiber fusion splicers utilize high resolution imaging combined with advanced alignment algorithms to accomplish this task. These assist the technicians in positioning the fibers to sub-micron accuracy, preserving the fragile polarization state and maximizing splice quality.

Key Features of PM Fiber Fusion Splicers

Modern PM fiber fusion splicers use dual fiber end face imaging, which enables the operator to visualize both ends of the fiber simultaneously. This is in contrast to just one view of the fiber end face, giving improved alignment.

Furthermore, modern splicers support ARC calibration to continuously adjust the fusion parameters for the splice as it is occurring. These splicers also support multi-splice angles, typically 0°, 45°, and 90°, to accommodate different PM fiber configurations.

Lastly, modern splicers are also intuitive for the operator and reduce operator errors and provide speed for splicing fiber, creating a valuable synergy for deploying PM networks.

Common Challenges in PM Fiber Splicing

Seamlessly splicing polarization-maintaining (PM) fibers presents a set of unique challenges based on the fibers’ sensitivity to polarization. The reader should consider the two biggest challenges, which are to manage polarization sensitivity during the fusion process and ensure the polarization state is maintained during cable handling. Some adjustments or disturbances can sometimes be very small in nature and still affect the polarization extinction ratio (PER) negatively.

Reducing splice loss and back reflection are both important concerns that need to be addressed to ensure the optimal performance of the network. Both technicians and scientists must utilize well-established fiber handling techniques with proper control of the fusion arc and splicing equipment to reduce the above losses, while considering environmental factors, such as relatively small temperature changes (i.e., in the global climate) and mechanical stress can affect splice quality through their effects on micro bending, tension and birefringence.

Lastly, proficiency in fiber optic fusion splicer troubleshooting applies to both technicians and scientists, to quickly, efficiently and effectively identify the root cause of any problem that may arise, on site or in the laboratory, contributing efficiently to producing repeatable, quality splices in the laboratory or high reliability under demanding conditions.

How to Choose the Right PM Fiber Fusion Splicer

When looking for quality PM fiber fusion splicers, there are many things to keep in mind. First, you want to look at the splicing accuracy. Accuracy is important because it will impact signal integrity and polarization maintenance. Second, speed will matter as the speed of splicing is going to affect the overall installation process and labor costs. Again, for large projects and deployments, it is ideal to have a faster device. The user experience is also important to consider and factors such as ease-of-use and affordability may also be indicators of a PM fiber splicer design. This is because using a PM fusion splicer that has more user-friendly features and functions will alleviate some of the risk of operator error and will provide less training time. Durability and portability of the splicer will also relate to the user experience; if your user or installer is using a splicer in different locations and environments, the durability and portability of the instrument will matter if autonomous employees or contractors are to travel to different site locations.

There are a handful of well known brands that manufacture PM fiber splicing models, each of which has different features and capabilities at varying price points. Investing in support and training is also essential to have operatives take full advantage of the PM fiber splicer and assure high quality splice.

Maintenance and Troubleshooting of PM Fiber Splicers

To achieve the best performance, PM fiber fusion splicers need to be cleaned and calibrated regularly. Cleaning the fiber holders, electrodes, and lenses can help to avoid contamination of the fiber, which can compromise the quality of the splice. When performed regularly, calibration will maintain the fusion arc to achieve repeatable performance.

Encountering a misalignment error, inconsistent performance of the arc, and software issues are common problems seen with fiber fusion splicers. A technician would be well advised to know the troubleshooting procedures included with his or her device, such as recalibration, cleaning, and firmware and software updates, to address possible solutions.

Updating firmware and software included with your splicer is helpful so that you can take advantage of new features and bug fixes, as well as improved automation, once the manufacturer’s pre-programmed settings are taken into consideration. Keeping the splicer up to date is a good way to ensure it remains effective and reliable over time.

Latest Innovations in PM Fiber Splicing Technology

Recent improvements in PM fiber splicing technology have made splicing processes more automated and made the need for operator intervention less important. These automated splicing systems have advanced with built-in intelligence, which can detect the fiber orientation and adjust the alignment automatically and consistently. The performance of these systems has essentially elevated the splice performance, quality, and consistency.

Some splicers can use polarization extinction ratio (PER) meters to measure the quality of the splice on-the-fly. This means the operator can optimize the splice performance for polarization retention and adjust seam quality immediately.

Emerging fiber types and creative splicing methods are enhancing PM fiber networks to deliver high speed and high tolerance to environmental conditions, all for next-generation optical communication systems.

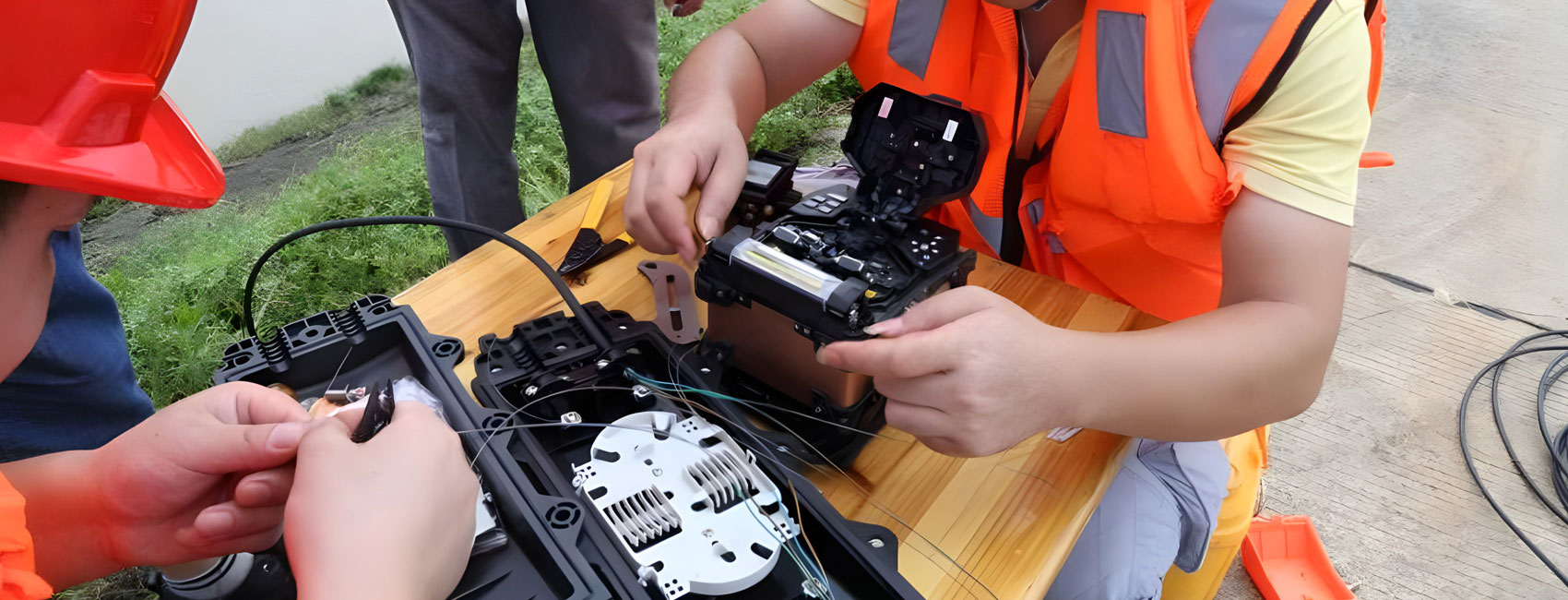

Engineer using a fiber fusion splicer outdoors, connecting cables at a field installation site.

Why PM Fiber Splicers Matter for Your Network

Fusion splicers designed for polarized fiber are an essential component to maintain signal integrity in polarized optical networks. Their capability of accurately aligning the cores of fibers and polarization directions allows for minimal splice loss while maintaining high polarization extinction ratios. These factors are critical in systems such as coherent communications and fiber optic sensors.

Selecting the proper splicers, as well as ensuring proper operator training and maintenance, can help achieve reliable and quality splices that will provide optimal performance and longevity to the network. Consequently, you will have a more reliable fiber optic network when combined with informed choice and best practices (PM Fiber Splicing) to your equipment and MFA splicer maintenance.